Multi-round acetic fermentation method and method for improving quality of aged vinegar based on multi-round acetic fermentation

A technology of acetic acid fermentation and old mature vinegar, applied in the field of vinegar processing, can solve the problems of incomplete fermentation of vinegar grains, loss of nutrients, etc., and achieve the advantages of promoting growth and reproduction, improving product quality, reducing acid pollution and loss of nutrients. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

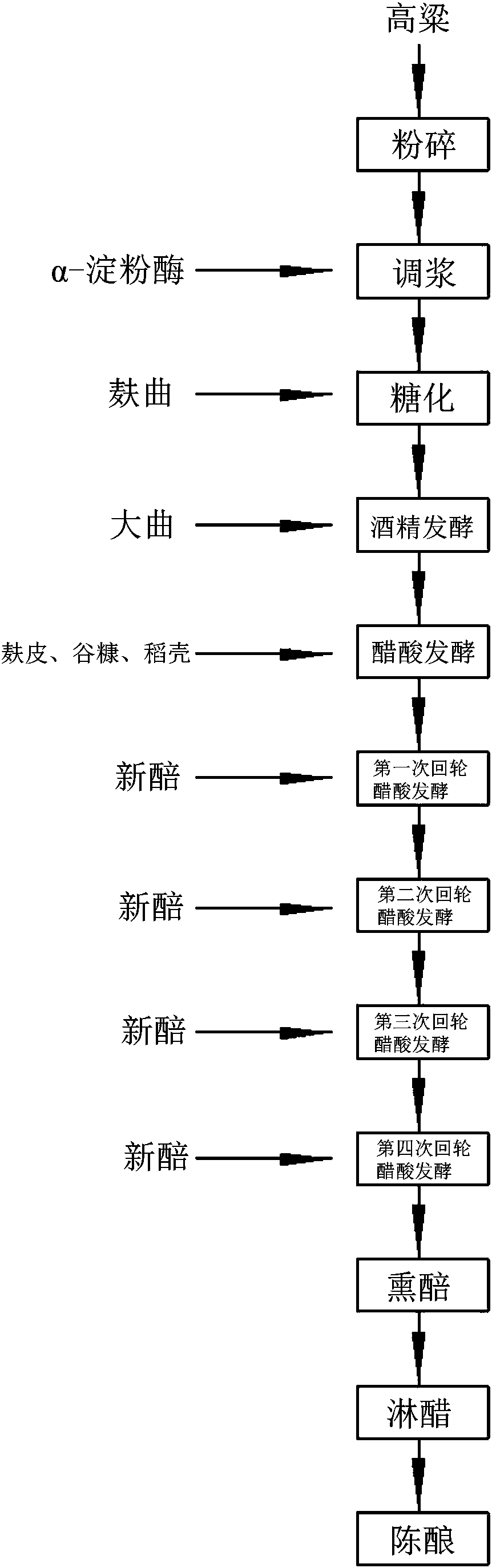

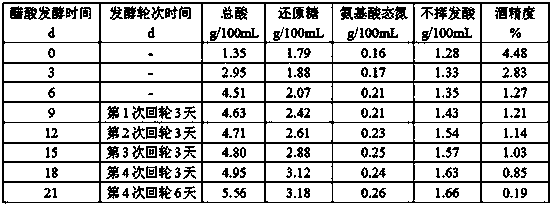

[0030] A method for improving the quality of mature vinegar based on multiple rounds of acetic acid fermentation, comprising the steps of:

[0031] (1) Raw material crushing: select high-quality sorghum, remove impurities and crush to 40 mesh, add hydrating material at 50°C~55°C for 4 hours.

[0032] (2) Cooking and gelatinization: After adding water, add 0.20% α-amylase of sorghum mass, mix well and control the temperature at 95°C~98°C for 1.0h.

[0033] (3) Saccharification: when the temperature drops to 60°C~65°C, add bran koji with a specific gravity of 15% sorghum and keep it for 1 hour.

[0034] (4) Alcoholic fermentation: the temperature is lowered to 32±1°C, adding Daqu 50% by weight of sorghum and 0.2% yeast, stirring evenly for alcoholic fermentation; two days before fermentation, open-top fermentation is carried out, and the temperature is controlled at 28°C~32°C ℃, seal on the third day, and carry out anaerobic fermentation for 10-12 days; when the alcohol content...

Embodiment 2

[0046] A method for improving the quality of mature vinegar based on multiple rounds of acetic acid fermentation, comprising the steps of:

[0047] (1) Raw material crushing: select high-quality sorghum, remove impurities and crush to 40 mesh, add hydrating material at 50°C~55°C for 4 hours.

[0048] (2) Cooking and gelatinization: After adding water, add 0.20% α-amylase of sorghum mass, mix well and control the temperature at 95°C~98°C for 1.0h.

[0049] (3) Saccharification: when the temperature drops to 60°C~65°C, add bran koji with a proportion of 20% sorghum and keep it for 1 hour.

[0050] (4) Alcoholic fermentation: the temperature is lowered to 32±1°C, adding Daqu 50% by weight of sorghum and 0.2% yeast, stirring evenly for alcoholic fermentation; two days before fermentation, open-top fermentation is carried out, and the temperature is controlled at 28°C~32°C ℃, seal on the third day, and carry out anaerobic fermentation for 10-12 days; when the alcohol content reach...

Embodiment 3

[0062] A method for improving the quality of mature vinegar based on multiple rounds of acetic acid fermentation, comprising the steps of:

[0063] (1) Raw material crushing: select high-quality sorghum, remove impurities and crush to 40 mesh, add hydrating material at 50°C~55°C for 4 hours.

[0064] (2) Cooking and gelatinization: After adding water, add 0.20% α-amylase of sorghum mass, mix well and control the temperature at 95°C~98°C for 1.0h.

[0065] (3) Saccharification: when the temperature drops to 60°C~65°C, add bran koji with a specific gravity of 18% sorghum and keep it for 1 hour.

[0066] (4) Alcoholic fermentation: the temperature is lowered to 32±1°C, adding Daqu 50% by weight of sorghum and 0.2% yeast, stirring evenly for alcoholic fermentation; two days before fermentation, open-top fermentation is carried out, and the temperature is controlled at 28°C~32°C ℃, seal on the third day, and carry out anaerobic fermentation for 10-12 days; when the alcohol content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com