Intelligent material allocation and binning U-shaped assembly line operation method and device

A streamlined and intelligent technology, applied in storage devices, packaging, packaging machines, etc., can solve problems such as low efficiency of transportation space utilization, errors in distribution and packing operations, lack of automated management, etc., and achieve efficient use of limited transportation space , reduce operating costs, and improve the effect of arrival speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

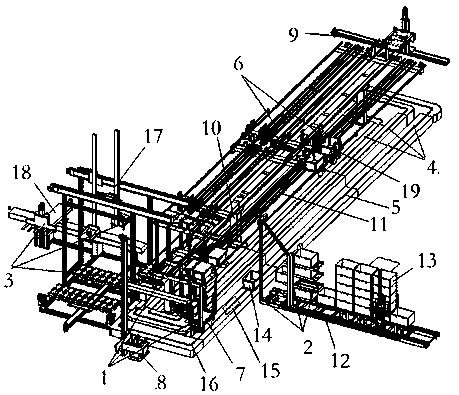

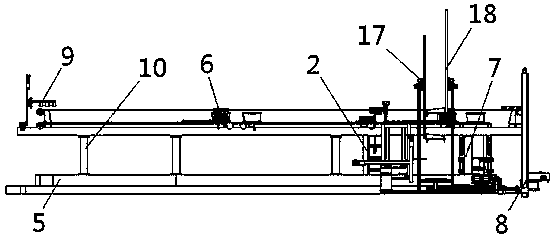

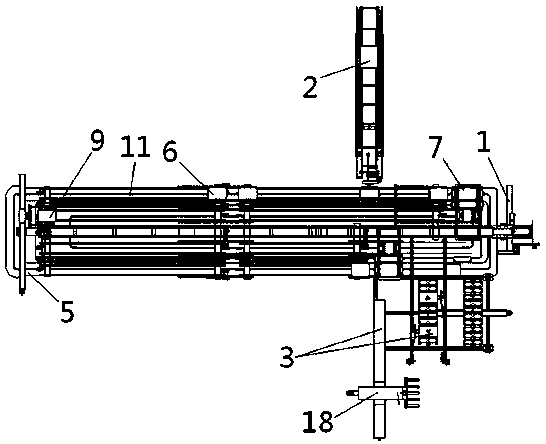

[0030] The accompanying drawings show an embodiment of the present invention, and it can be seen from the accompanying drawings that the present invention relates to a material intelligent distribution and boxing assembly line operation system, including a delivery box cover storage and distribution system 1, a material storage system 2. The delivery box stacking and loading system 3 and the delivery box distribution transmission system 4; among them, the delivery box distribution transmission system 4 is a "U"-shaped intelligent assembly line 5, and the material storage system 2 is distributed in On each operating station outside the "U"-shaped intelligent assembly line 5, the storage system device 6 of the delivery frame cover storage and distribution system 1 is located above the "U"-shaped intelligent assembly line 5, and the delivery The sub-frame system device 7 of the frame cover storage and distribution system 1 is located on one side of the head of the "U"-shaped intel...

Embodiment 2

[0037] The basic principle of Embodiment 2 is the same as that of Embodiment 1, except that the structure of the intelligent assembly line is different. It is an intelligent material distribution and packing assembly system, including a storage and distribution system for delivery frame covers, Material storage system, delivery box stacking and loading system, and delivery box distribution transmission system; among them, the delivery box distribution transmission system is a ring-shaped intelligent assembly line, and the material storage system is distributed on the outside of the ring-shaped intelligent assembly line On each work station, and according to the system instructions, carry out distribution for the passing delivery frame; the delivery frame cover storage and distribution system includes the delivery frame cover storage system device and the delivery frame cover sub-frame system device, the delivery The frame cover collection and storage system device collects and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com