Car dashboard mesh cloth hanging cloth mechanism

A technology for automotive dashboards and mesh fabrics, which can be applied to home appliances, other home appliances, and household components. It can solve the problems of reduced overall production capacity, low efficiency, and slow production cycle, and achieve stable driving force, high position accuracy, and stability. sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

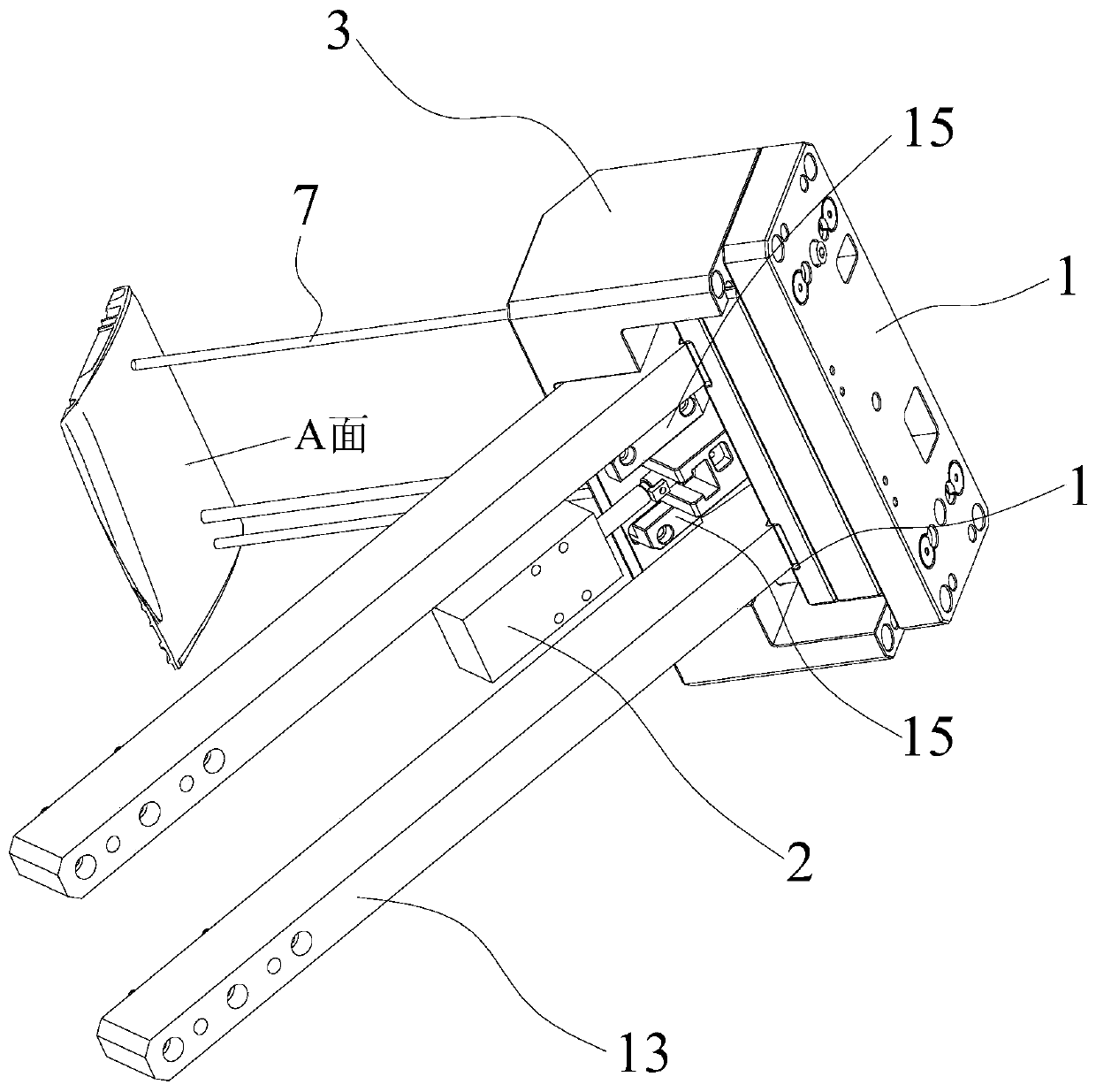

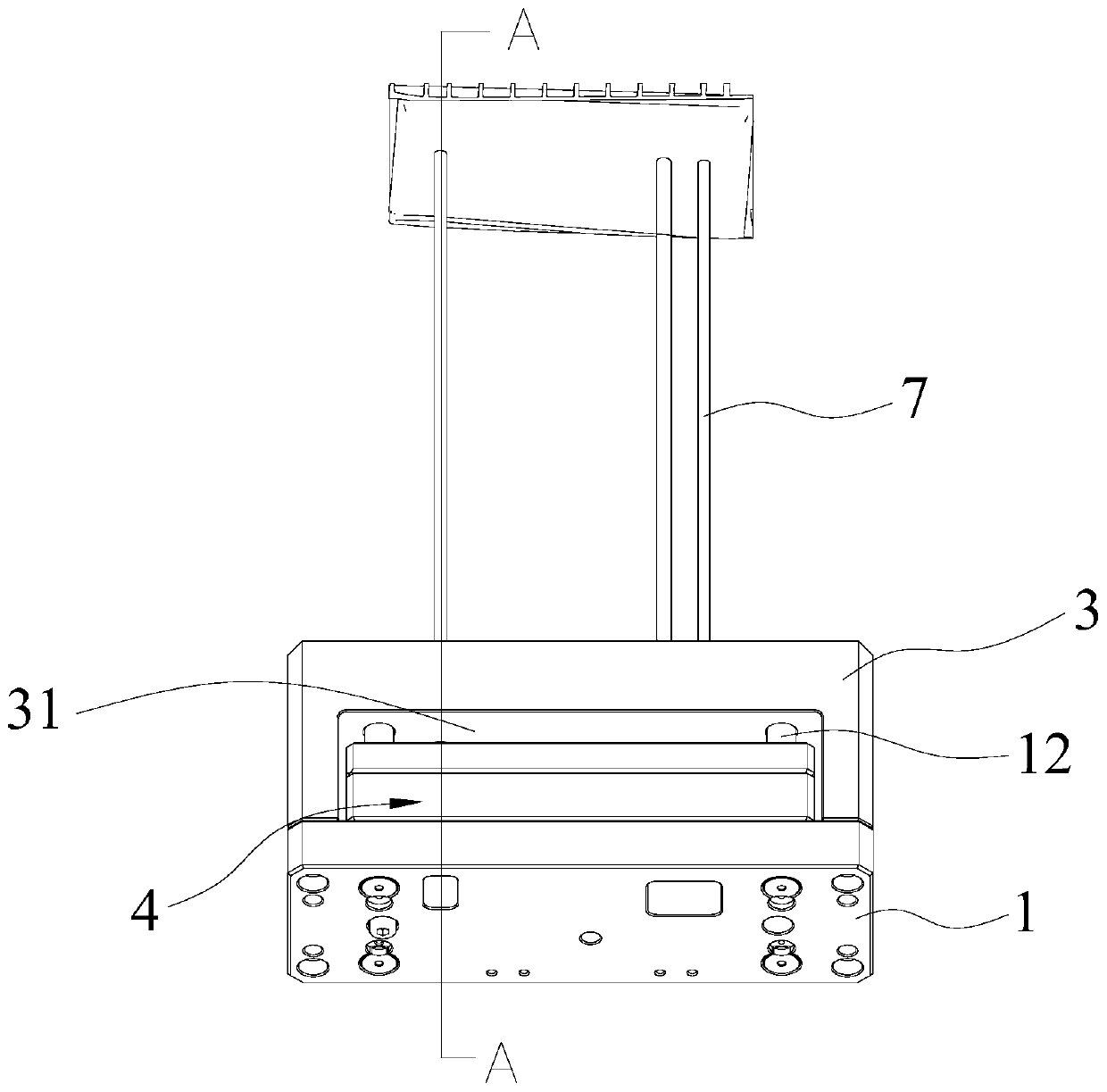

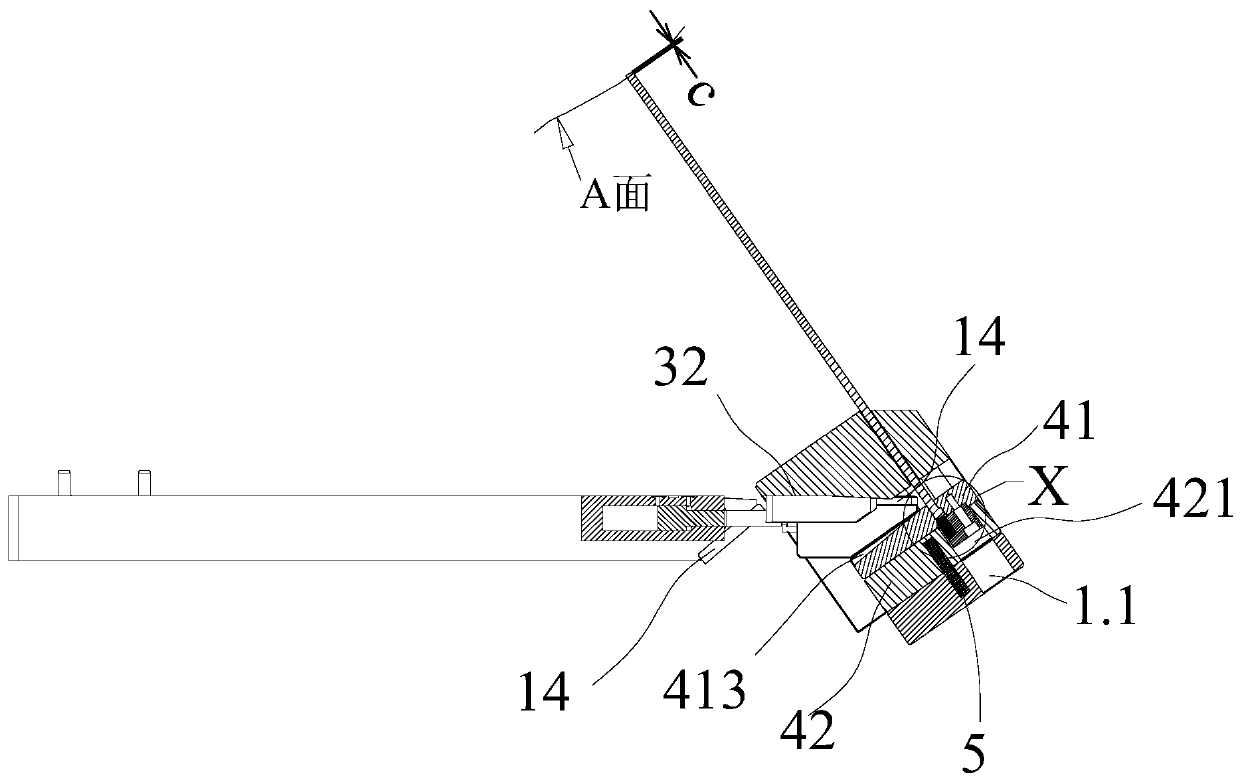

[0022] Such as Figure 1~5 As shown, the present invention provides a kind of cloth hanger mechanism for automobile instrument panel, which comprises a bottom plate 1 and an oil cylinder 2. 3. The end of the fixed plate 3 close to the installation base plate 1 is provided with an installation cavity 31, and the thimble plate 4 is slidably provided in the installation cavity 31. After the thimble plate 4 is installed in the installation cavity 31, there is a gap between the thimble plate 4 and the installation cavity 31. There is a gap for the thimble plate 4 to slide up and down in the installation cavity 31, and a large spring 5 is provided between the side of the thimble plate 4 close to the installation base 1 and the installation base 1, and a hanging spring 5 is provided on the thimble plate 4 to slide. The cloth needle 6 and the hanging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com