Bowl-shaped plug assembly tool and application method thereof

A technology for assembling tools and bowls, which is applied in the direction of manufacturing tools, hand-held tools, workpiece clamping devices, etc., can solve the problems of bowl-shaped blockage, easy knocking, internal combustion engine safety hazards, and low installation efficiency, etc., to improve product quality, Safe and reliable sealing performance, the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0037] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

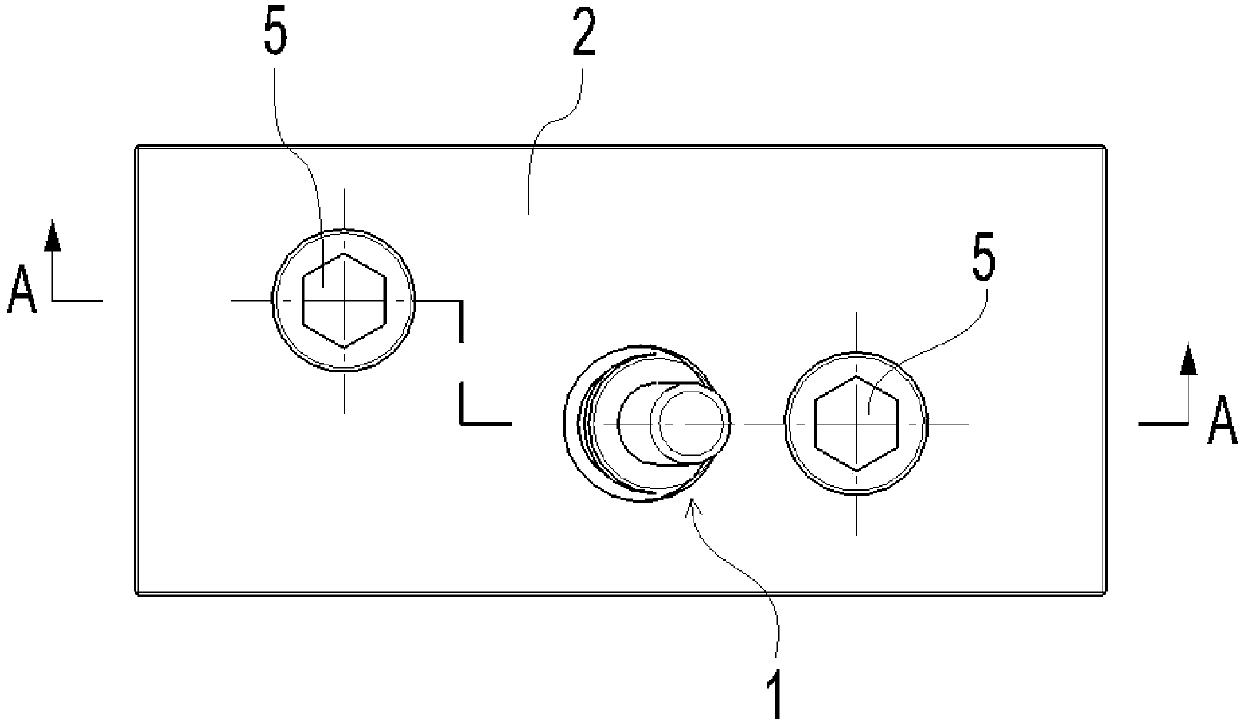

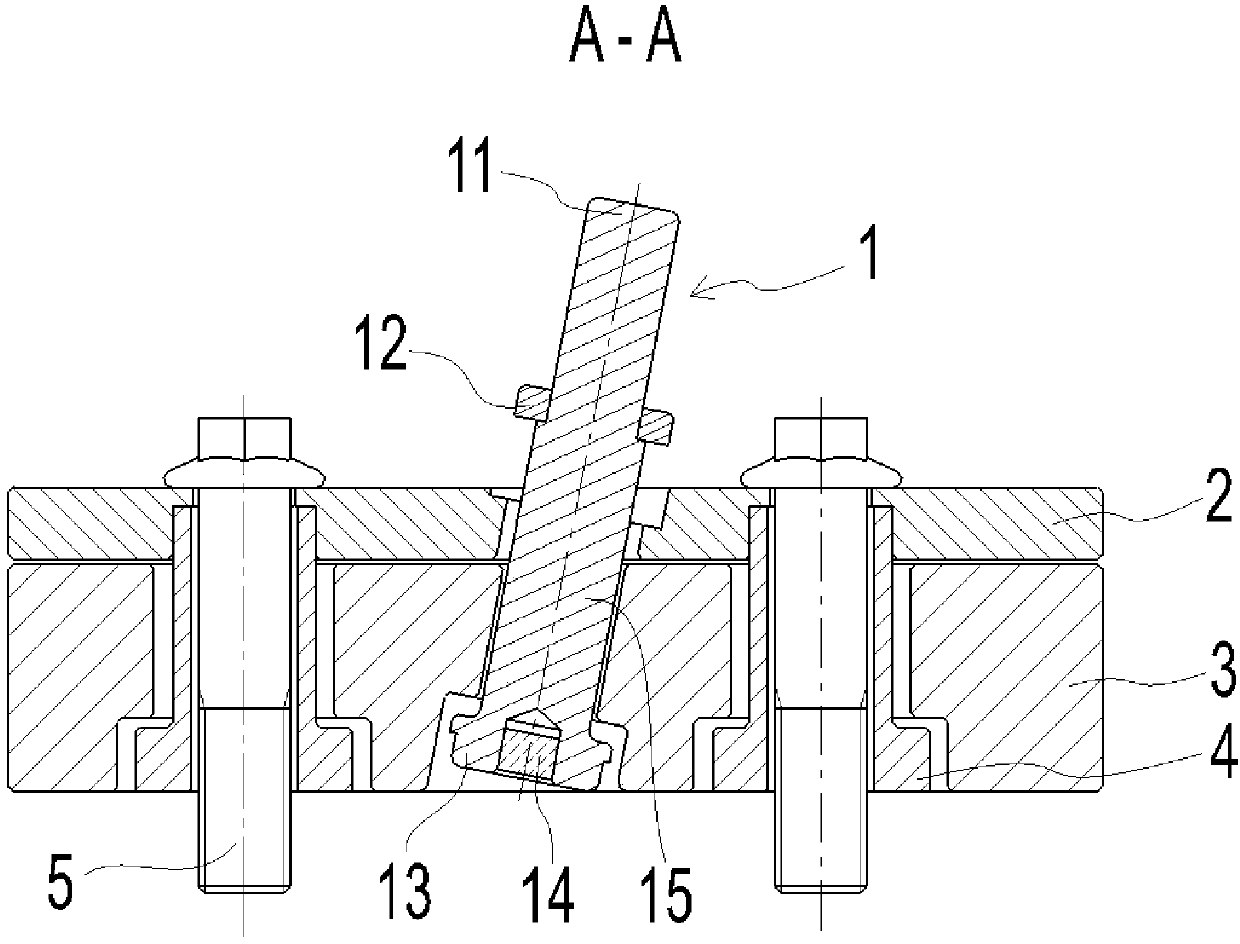

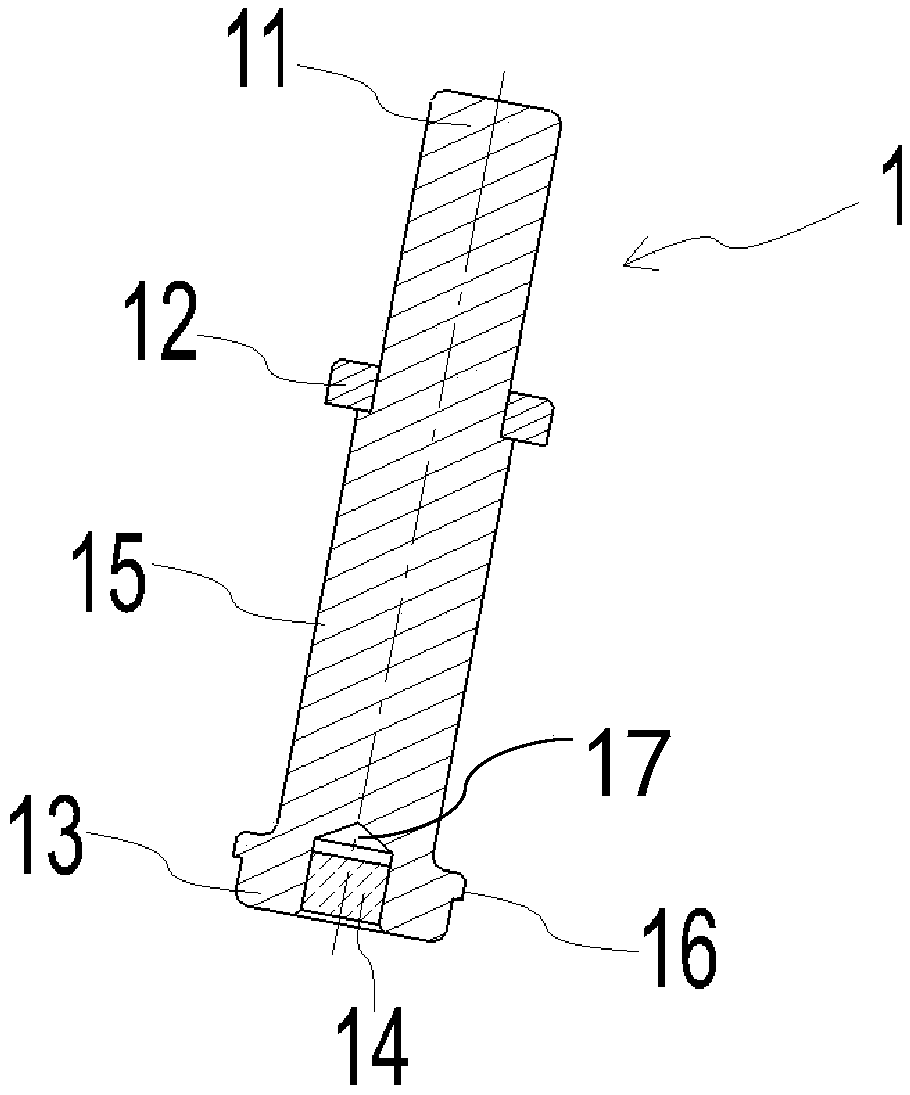

[0038] Such as Figure 1 to Figure 2 as shown, figure 1 is a top view of an assembly tool for a bowl-shaped plug according to the present invention. figure 2 is a cross-sectional view A-A of an assembly tool for a bowl-shaped plug according to the present invention. An assembly tool for a bowl-shaped plug according to a specific embodiment of the present invention, which is used to block the inclined oil passage 61 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com