Concrete additive production reactor

A reaction device and additive technology, applied in the field of concrete additive production reaction device, can solve problems such as insufficient mixing, and achieve the effects of increasing the amount of mixing, uniform mixing of raw materials, and strengthening of the mixing function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

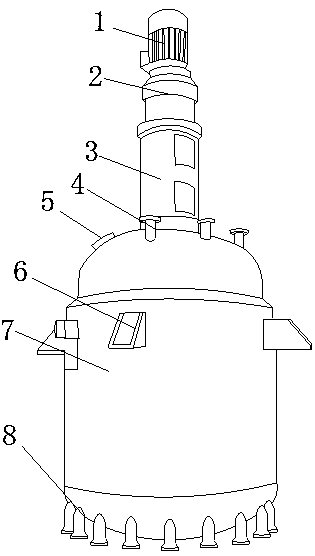

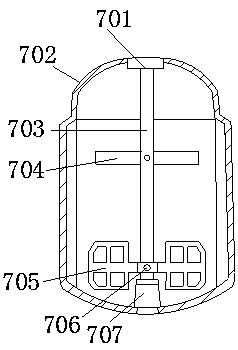

[0019] see figure 1 , figure 2 , the present invention provides a technical solution of a concrete additive production reaction device: its structure includes a motor 1, a reducer 2, a frame 3, an exhaust port 4, a cover 5, a support 6, a tank body 7, and a support frame 8, The reducer 2 is embedded and connected to the frame 3, the exhaust port 4 is integrated with the tank body 7, the cover 5 is embedded and connected to the tank body 7, and the support frame 8 is arranged on the tank body 7, the tank body 7 includes a fixed disk 701, a casing 702, a rotating rod 703, a balance rod 704, a stirring paddle 705, a paddle fixing block 706, and a discharge port 707. The fixed original disk 701 is embedded and connected to the casing In 702, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com