Breathable three-dimensional shoe upper structures and making process thereof

A production process, three-dimensional technology, applied in the direction of shoe uppers, footwear, lamination auxiliary operations, etc., can solve the problems of poor flexibility and variability, inconsistent with diversification, complex processes, etc., to achieve good aesthetics, enhance aesthetics, Strong and stable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

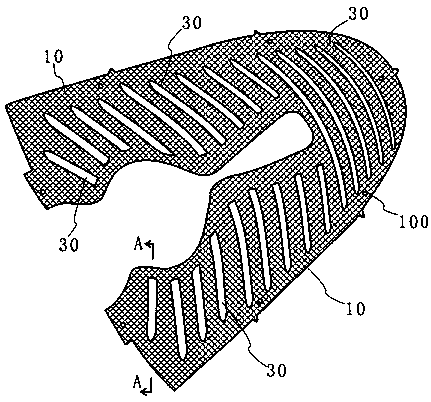

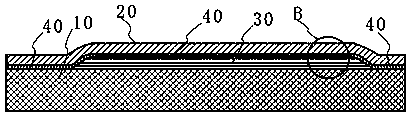

[0031] like Figure 1-3 As shown, this embodiment provides a breathable three-dimensional upper structure, including a mesh base layer 10, a mesh surface layer 20, and a three-dimensional offset printing layer 30 and a joint layer 40 between the mesh base layer 10 and the mesh surface layer 20, Both the outline shape of the mesh surface layer 20 and the outline shape of the mesh base layer 10 correspond to the overall outline shape of the shoe upper.

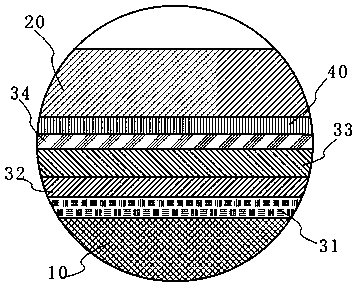

[0032] In this embodiment, the three-dimensional offset printing layer 30 is successively an oily varnish layer 31, a water-based three-dimensional gold oil layer 32, a foaming color paste layer 33 and a dot printing layer 34 from bottom to top, and the water-based three-dimensional gold oil layer 32 and hair The thickness ratio of the bubble color paste layer 33 is (5~6): 4, and the three-dimensional offset printing layer 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com