Method and device for managing humidity sensitive element

A technology of a humidity-sensitive element and a management method, which is applied in the field of the management method and device of the humidity-sensitive element, can solve the problems of waste, loss, and the quality of electronic products cannot be well guaranteed, so as to ensure the quality and reduce the loss and waste. , the effect of improving the efficiency of management and control and the quality of management and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

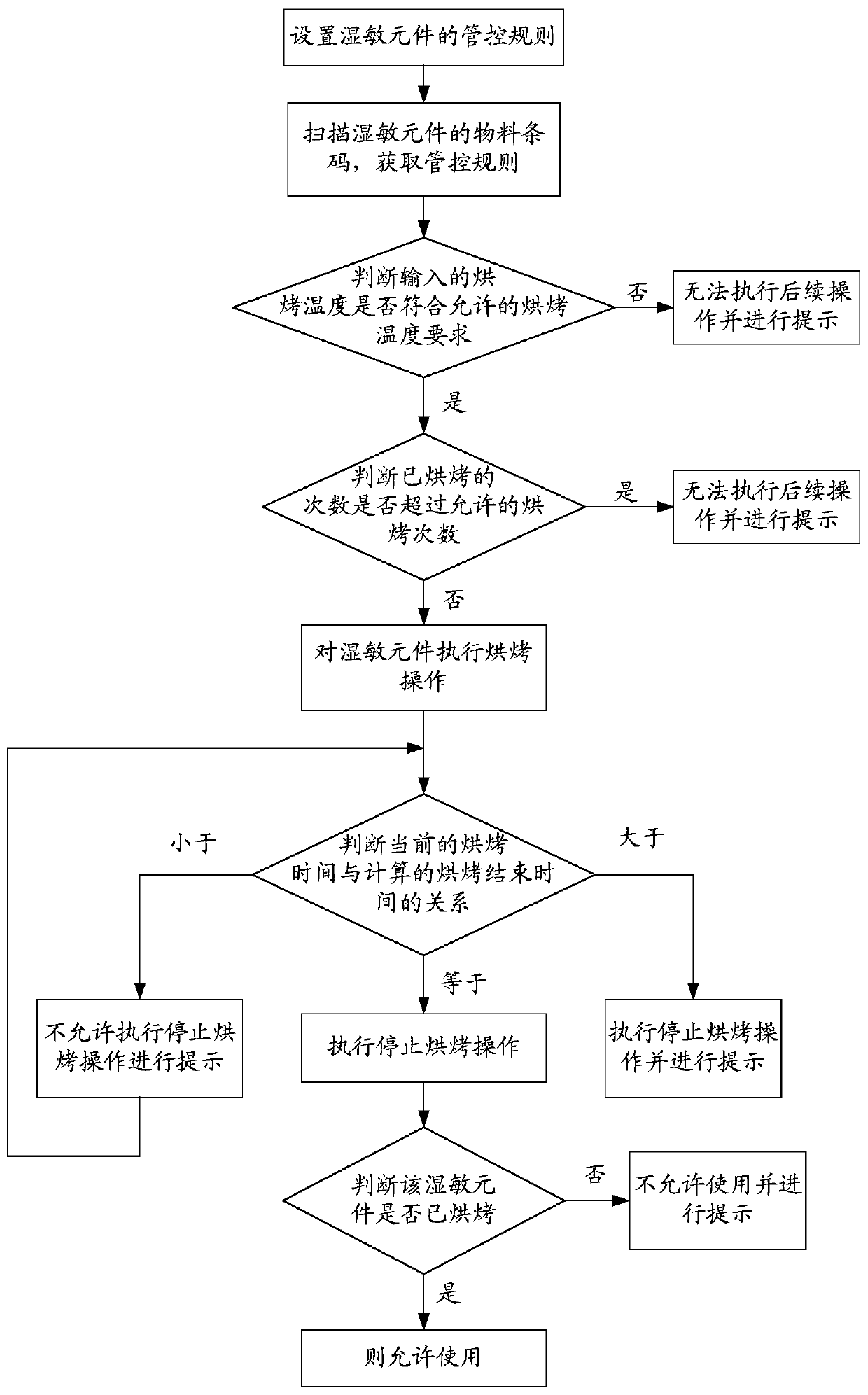

[0039] see figure 1 As shown, a preferred embodiment of the management method of a moisture sensitive element of the present invention, the method includes the following steps:

[0040] Step S1, set the control rules of the humidity sensor, the control rules at least include setting the allowable baking temperature, baking time and baking times; for example, in specific implementation, you can set the allowable The baking temperature is 60°C, the allowed baking time is 30 minutes, and the allowed baking times are 20 times; it is also possible to set the allowed baking temperature of a certain humidity sensor B to 72°C, and the allowed baking time is 55 minutes, the number of bakes allowed is 15 and so on.

[0041] Step S2, scan the material barcode on the humidity sensor, and obtain the control rules of the humidity sensor according to the material barcode; input the baking temperature on the baking interface, and judge whether the input baking temperature meets the allowable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com