Environmental-friendly baking oven

A baking oven, an environmentally friendly technology, applied in the field of baking ovens, can solve the problems of poor baking effect, ugly appearance of the oven, unhealthy and unhygienic food, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

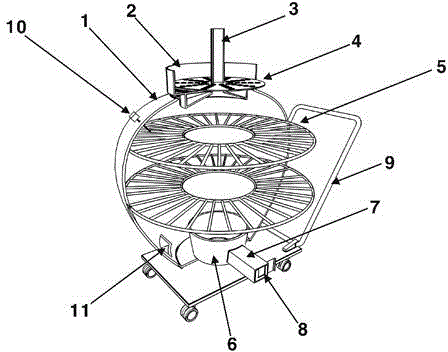

[0020] Example 1, such as figure 1 The schematic diagram of the oven structure is shown. This diagram is a schematic diagram of the structure after the cylinder is thrown away. The oven is mainly composed of cylinder 1, heat preservation pot 2, exhaust pipe 3, grate 4, baking frame 5, and carbon basin Fixing frame 6, oxygen pipe 7 form.

[0021] Cylinder 1 adopts a large crock pot or ceramic cylinder. The shape of cylinder 1 is a spherical shape. The size of cylinder 1 can be adjusted according to needs. The height of cylinder 1 is 50cm-100cm, and the maximum diameter of cylinder 1 is 40cm to 80cm, usually the ratio of the height of the cylinder 1 to the maximum diameter of the middle is 5:4, the upper end of the cylinder 1 with a spherical segment structure has an upper port, the lower end is a flat bottom, and the inner bottom of the cylinder 1 is welded with a carbon basin on the flat bottom Fixture 6, the upper port is equipped with insulation pot 2, the diameter of the u...

Embodiment 2

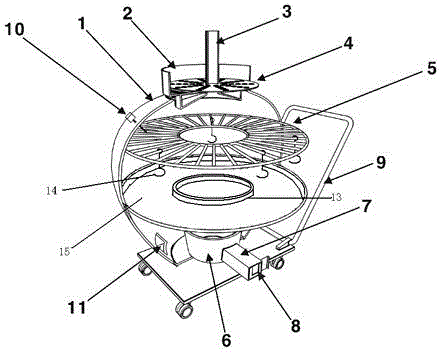

[0032] Embodiment 2 The baking oven of this embodiment is basically the same as that of Embodiment 1, the difference is that the heat preservation pot 2 is a pan with a through hole in the middle, and is placed on the cylinder body 1 to serve as the upper cover of the cylinder body 1. Exhaust pipe 3 passes through the through hole of heat preservation pot 2 and is welded with heat preservation pot 2 to form an integral body. The lower port of exhaust pipe 3 is an inverted bell mouth, that is, the bottom port is greater than the upper port, which is convenient for the discharge of steam in cylinder body 1.

Embodiment 3

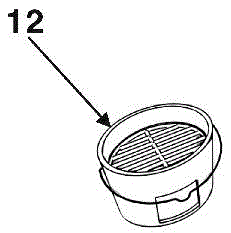

[0033]Embodiment 3 The specific working process of this baking oven is as follows: first ignite the charcoal in the carbon basin 12, hook the carbon basin 12 with a fire hook and place it in the carbon basin fixing frame 6 of the cylinder body 1, preheat the oven, After reaching a certain temperature according to the thermometer 10, place the food to be baked on the baking rack 5 for baking, and compare the temperature shown by the thermometer 10 with the optimum temperature required for baking, and control the food by adjusting the temperature. The valve 8 controls the amount of trophism, and adjusts the temperature to the optimum temperature for baking. After the food is baked, take out the heat preservation pot 2, and pass the baked food through the special L-shaped clip, from the top of the oven to the bottom of the oven. In the oven, pass through the inner ring of the upper baking rack 5 and clamp the food of the lower baking rack 5, take it out and place it on the grate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com