Method for filling dug well or waste pumping well with sand for recharging underground water and storing water

A technology of groundwater and sand, applied in water supply devices, drinking water devices, water resources protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

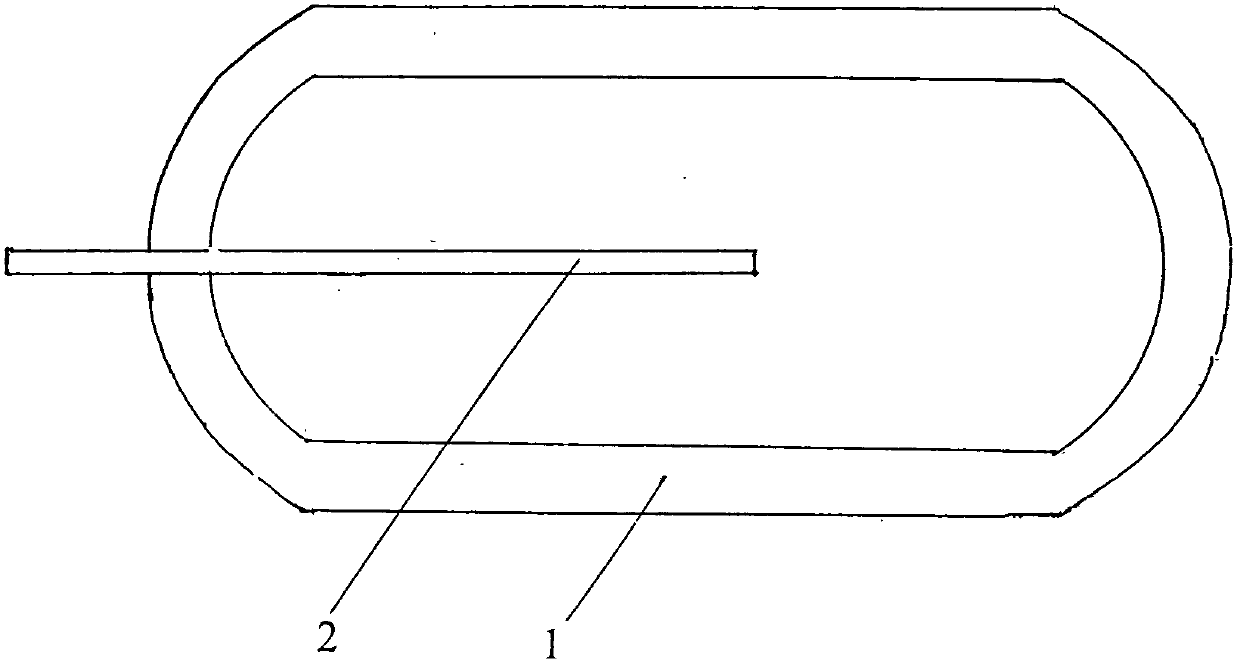

[0023] Pre-made water column ( figure 1 ) or water polo ( figure 2), using pure pebbles and cement instead of sand, the cement blocks poured from pure pebbles and cement, because there will be gaps between the pebbles, water can seep through, considering the wall thickness of the water column (1) or the wall of the filter ball The thickness (3) is 40mm to 60mm, and the middle is a hollow cylinder or a hollow sphere. The gap between the stones is water seepage. If the setting is long, the volume can be set large. The diameter of the sphere can only be smaller than the diameter of the wellhead, so the volume is limited. If the pumping volume is small, use a spherical one, and if the pumping volume is large, use a cylinder. If necessary, the cylinder should be lengthened. The water column and the water ball are placed in the well, surrounded by sand, without external damage. The ordinary stones are cleaned, mixed with ordinary cement, and the mold is poured. The production is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com