Device for accurately taking membrane in single-piece mode

A technology of a material retrieving device and diaphragm, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty in maintaining the ideal shape and insufficient softness and rigidity of the diaphragm, so as to save costs, overcome insufficient softness and rigidity, and avoid damaged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

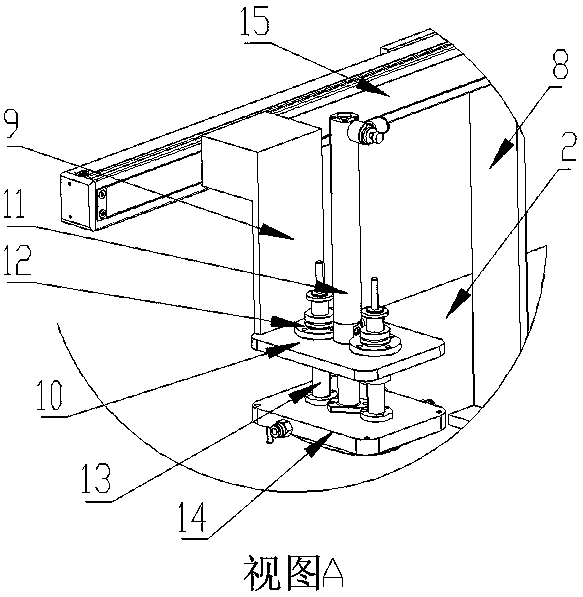

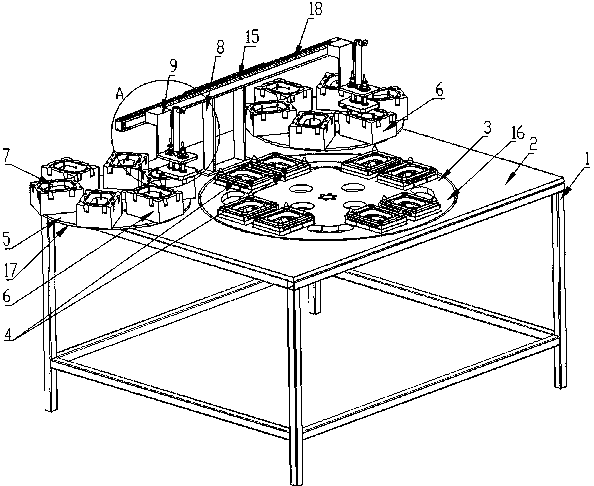

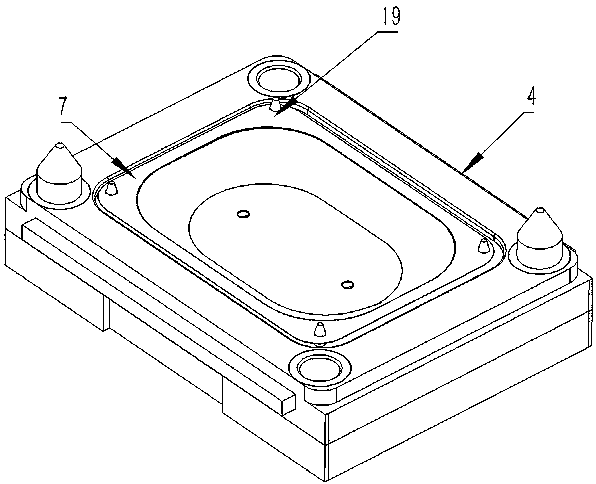

[0013] Embodiment 1, see Figure 1 to Figure 5 , a diaphragm accurate sheet-feeding device, comprising a frame group 1, a table 2, a fixture circulation platform 3, a diaphragm assembly fixture 4, a diaphragm cycle feeding rotary table 5, a diaphragm carrier 6, a diaphragm 7. Bracket 8, slider fixing block 9, lifting cylinder fixing plate 10, lifting cylinder 11, linear bearing assembly 12, guide shaft 13, profiling suction cup group 14, transfer module 15, fixture circulation mechanism 16, diaphragm circulation Feeding mechanism 17, diaphragm transfer and suction mechanism 18, diaphragm positioning pin 19, adsorption small hole 20, air pipe joint interface 21, profiling suction cup body 22, negative pressure chamber 23, diaphragm positioning pin avoidance hole 24; : The clamp circulation mechanism 16, the diaphragm circulation feeding mechanism 17, and the diaphragm transfer and suction mechanism 18 are respectively installed on the table board 2 of the frame group 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com