Waterproof and moistureproof covered electrode coating suitable for underwater wet welding and spraying method thereof

A wet welding and welding rod technology, applied in the coating, the device for coating liquid on the surface, the pretreatment surface, etc., to achieve uniform properties, solve the problem of moisture absorption, and have obvious effects of waterproofing and moisture-proofing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

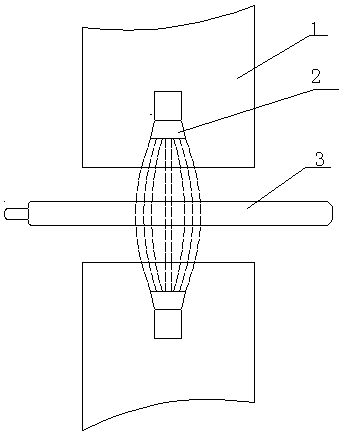

[0025] The outer layer of the electrode is covered with a coating, and one end of the electrode is not covered with a coating. A waterproof coating is sprayed on the coating by electrostatic spraying, including the following steps:

[0026] (1) Preparation of coating materials: The coating is proportioned according to the following parts by weight: 65 parts of epoxy powder, 15 parts of curing agent, 10 parts of rare earth oxide, and 10 parts of fluorite powder. Among them, the particle size of epoxy powder 80 μm, the curing agent is a mixture of T-31 curing agent and diethylenetriamine, and the powder is mixed evenly;

[0027] (2) Pretreatment of welding rods: firstly dry the welding rods at 220°C for two hours, and use the heat generated by the temperature during drying to absorb a large amount of epoxy powder and other coating powders, even if the surface of the welding rods has Unevenness or shrinkage cavity defects are also easily filled and covered by powder, which can en...

Embodiment 2

[0032] The components of the coating in this embodiment are proportioned according to the following parts by weight: 70 parts of epoxy powder, 16 parts of curing agent, 12 parts of rare earth oxide, 12 parts of fluorite powder, the particle size of the epoxy powder is 70 μm, The rest of the steps are the same as in Example 1, and will not be repeated here, wherein, the electrostatic voltage is 70 kV, and the spraying distance is 160 mm.

[0033] After cooling to form a film, visually observe that the coating surface is smooth, uniform in color and free of bubbles. Use a thickness gauge to detect the coating thickness at three different positions on the electrode, and measure the coating thickness at 4 points evenly distributed around the circumference of each position. The coating thicknesses at these three positions are 0.17mm and 0.18mm respectively. , 0.21mm, in line with the design requirements of the coating.

Embodiment 3

[0035] The components of the coating in this embodiment are proportioned according to the following parts by weight: 75 parts of epoxy powder, 20 parts of curing agent, 15 parts of rare earth oxide, 15 parts of fluorite powder, the particle size of the epoxy powder is 120 μm, The rest of the steps are the same as in Example 1, and will not be repeated here, wherein, the electrostatic voltage is 75 kV, and the spraying distance is 190 mm.

[0036] After cooling to form a film, visually observe that the coating surface is smooth, uniform in color and free of bubbles. Use a thickness gauge to detect the coating thickness at three different positions on the electrode, and measure the coating thickness at 4 points evenly distributed around the circumference of each position. The coating thicknesses at these three positions are 0.18mm and 0.21mm respectively. , 0.21mm, in line with the design requirements of the coating.

[0037] In summary, the present invention uses a powder electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com