Dust recovery device

A technology of dust recovery and smoke dust, which is applied in the field of environmental protection and resource reuse, can solve the problems of shortened filter bag life and affect dust removal efficiency of bag filter, so as to prolong the life of filter bag, avoid dust flying, and facilitate dust settlement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further detailed explanation through specific implementation mode below:

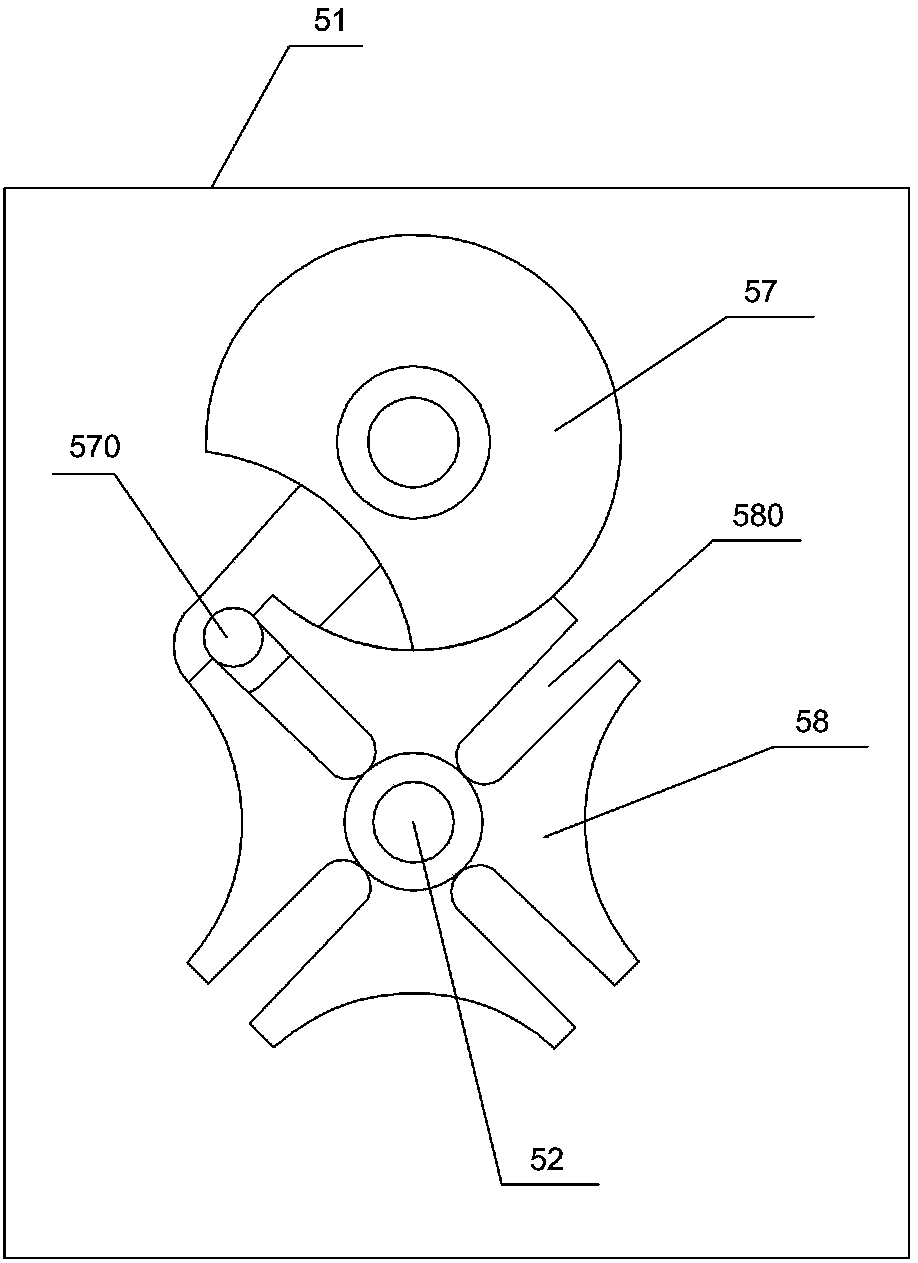

[0023] The reference signs in the drawings of the description include: smoke and dust pipe 1, water cooling pipe 2, water suction ball 3, bag filter 4, installation box 51, rotating shaft 52, cam 53, louver 54, high-pressure spray head 55, perforated louver 56 , dial 57, round pin 570, sheave 58, radial groove 580.

[0024] Such as figure 1 As shown, the dust recovery device of this embodiment includes a dust pipe 1, on which a cooling mechanism, a pre-dust removal mechanism, a dust drying mechanism and a bag filter 4 are arranged in sequence along the direction of the dust.

[0025] The cooling mechanism is used to reduce the temperature of the dust. The cooling mechanism adopts the water cooling method, including the water cooling pipe 2 attached to the outer wall of the dust pipe 1. The water cooling pipe 2 is filled with flowing cold water. Institutional movement.

[0026] The pre-dust rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com