Organic light-emitting diode display device and manufacturing method thereof

A light-emitting diode and display technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as low production efficiency, long production process, and bad accumulation, so as to improve efficiency, reduce defect rate, and improve The effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

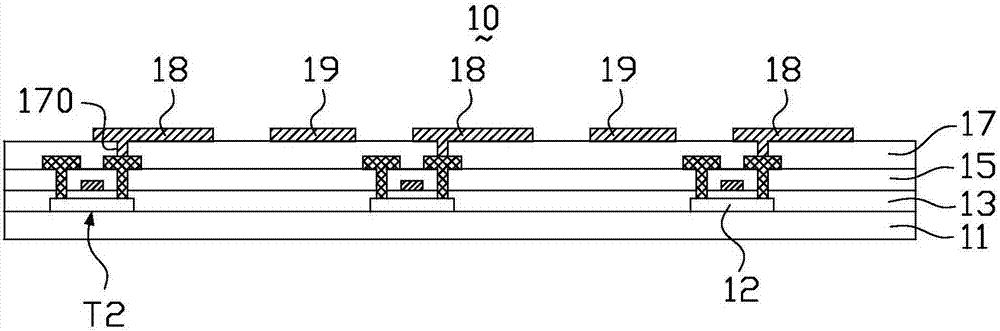

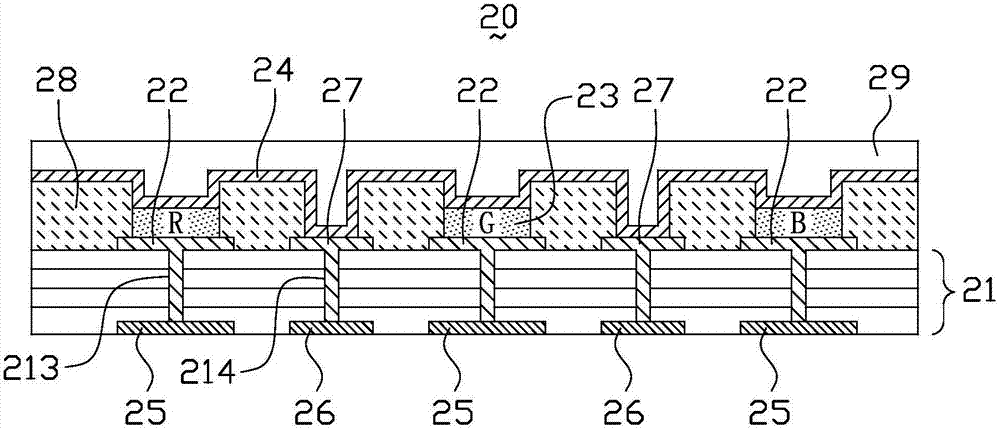

[0047] figure 1 is a schematic cross-sectional view of the array element substrate in the first embodiment of the present invention, figure 2 is a schematic cross-sectional view of the organic light emitting diode substrate in the first embodiment of the present invention, image 3 It is a schematic cross-sectional view of the organic light emitting diode display in the first embodiment of the present invention, please also refer to Figure 1 to Figure 3 , the organic light emitting diode display comprises an array element substrate 10 and an organic light emitting diode substrate 20, the array element substrate 10 and the organic light emitting diode substrate 20 are manufactured separately, and a thin film transistor array element (TFT) is formed on the array element substrate 10 An organic light emitting diode (OLED) is formed on the organic light emitting diode substrate 20, and then the two substrates 10, 20 are bonded together to form the organic light emitting diode d...

no. 2 example

[0080] Figure 10 is a schematic cross-sectional view of an organic light emitting diode display in a second embodiment of the present invention, Figure 11 is a schematic plan view of the array element substrate in the second embodiment of the present invention, Figure 12 It is a schematic front view of the organic light emitting diode substrate in the second embodiment of the present invention, Figure 13 It is a schematic diagram of the back of the organic light emitting diode substrate in the second embodiment of the present invention, please also refer to Figure 10 to Figure 13 , the structure and manufacturing method of the organic light emitting diode display in the second embodiment are basically the same as those in the first embodiment above, where the main difference is that the second bonding electrodes 19 on the array element substrate 10 are only distributed on the array element substrate 10 peripheral edge area and connected into a "mouth" shape (such as F...

no. 3 example

[0082] Figure 14 is a schematic cross-sectional view of an organic light emitting diode display in a third embodiment of the present invention, Figure 15 It is a schematic front view of the organic light emitting diode substrate in the third embodiment of the present invention, Figure 16It is a schematic diagram of the back of the organic light emitting diode substrate in the third embodiment of the present invention, please also refer to Figure 14 to Figure 16 , the structure and manufacturing method of the organic light emitting diode display in the third embodiment are basically the same as those in the first embodiment, the main difference is that the second bonding electrodes 19 on the array element substrate 10 are only distributed on the array element substrate 10 peripheral edge area and connected into a "mouth" shape (see Figure 11 shown), the fourth bonding electrode 26 and the fifth bonding electrode 27 are not provided on the organic light emitting diode sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com