Optical Components and Optical Modules

A technology of optical components and photoelectric conversion elements, applied in the field of optical modules, can solve the problems of large peak value and low 3dB cut-off frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

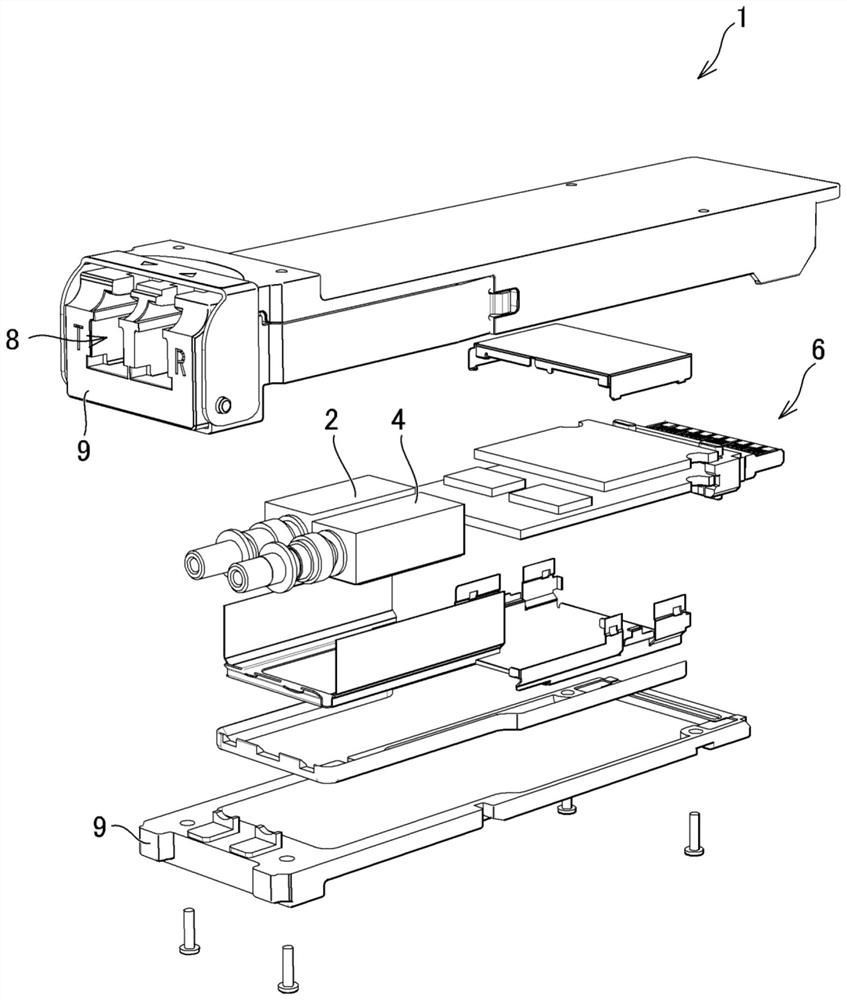

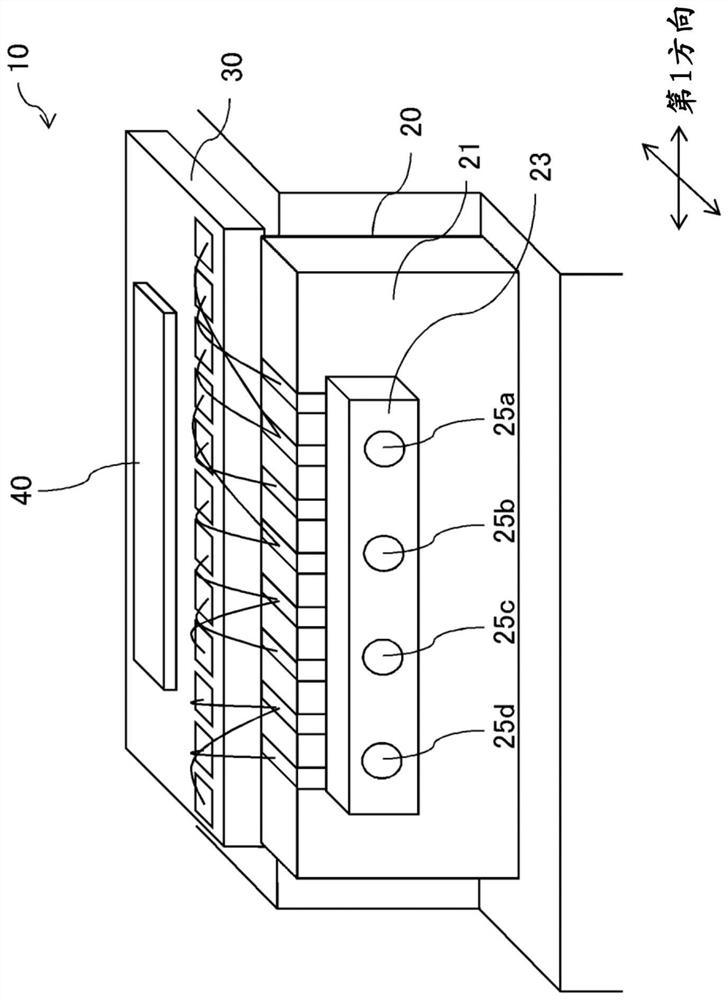

[0042] figure 1 It is an exploded perspective view of the optical module 1 according to the first embodiment. The optical module 1 is built with two optical components. Specifically, it is an optical sending assembly 2 (TOSA: Transmitter Optical Sub-Assembly) for converting electrical signals into optical signals and an optical receiving assembly 4 (ROSA: Transmitter Optical Sub-Assembly) for converting optical signals into electrical signals Receiver Optical Sub-Assembly, light receiving sub-assembly). On the transmitting side, the electrical signal transmitted from the main substrate (not shown) is passed to the circuit substrate in the optical module 1 via the electrical interface 6 to be converted into an optical signal, and the optical signal is transmitted through the optical interface 8 . On the receiving side, an optical signal is received, and an electrical signal is output to a main-side substrate (not shown). The optical module 1 has a housing 9 composed of a pa...

no. 2 Embodiment approach

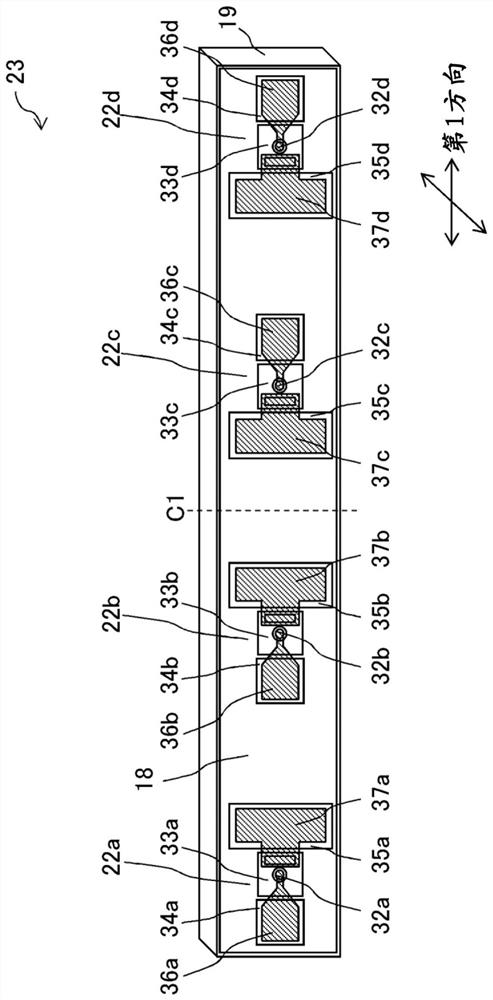

[0084] Figure 11 It is a perspective view of the light-receiving element array 230 according to the second embodiment viewed from the front side. The light-receiving element array 230 according to the second embodiment has the same light-receiving element as that according to the first embodiment, except that the arrangement of each light-receiving element 22 and the connection wiring connecting each light-receiving element 22 to the element terminal group 24 are different. The structure of the array 23 is the same, and therefore, repeated descriptions are omitted. Here, a configuration different from that of the light receiving element array 23 according to the first embodiment will be described.

[0085] In the light receiving element array 230 , a first light receiving element 22 a , a second light receiving element 22 b , a third light receiving element 22 c , and a fourth light receiving element 22 d are sequentially formed on the semi-insulating Fe-doped InP substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com