Testing method of rock true triaxis with ultrasonic phased array real-time imaging system with

A real-time imaging system, ultrasonic phased array technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem that the nature and size of the acoustic emission source cannot be given, the shape of the crack cannot be obtained, and Size, can only give the general location of cracks, etc., to achieve the effect of intuitive results, small size, and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

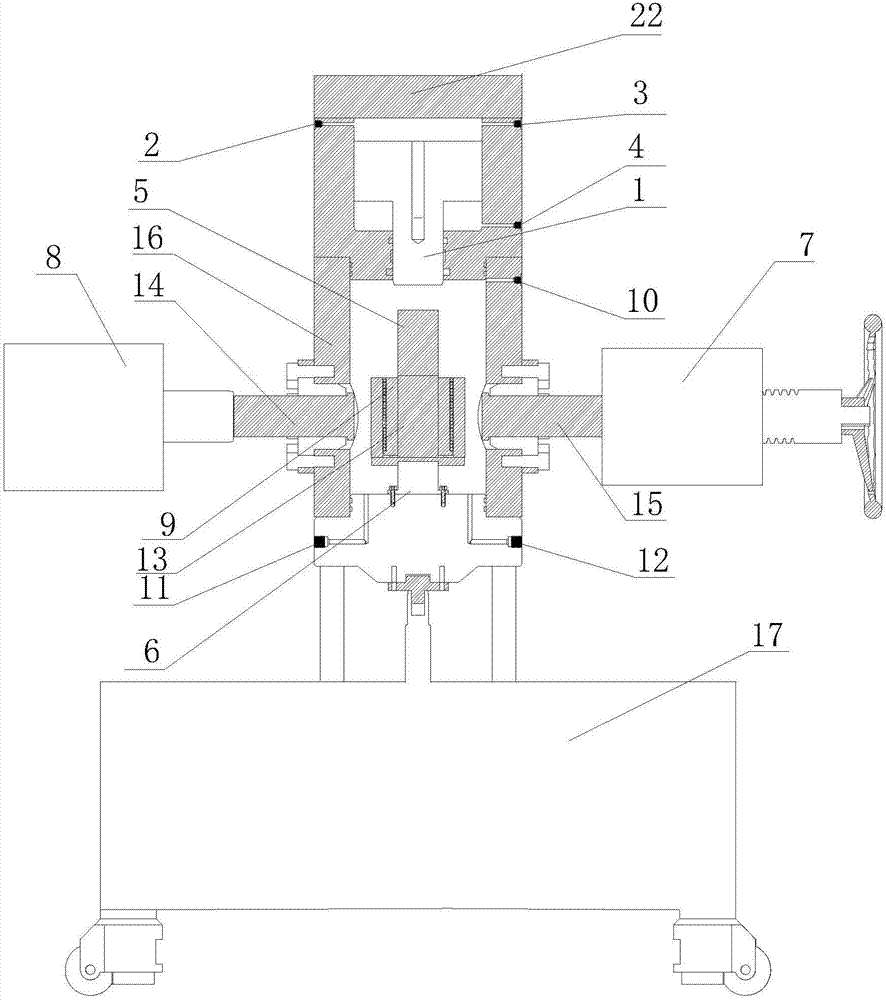

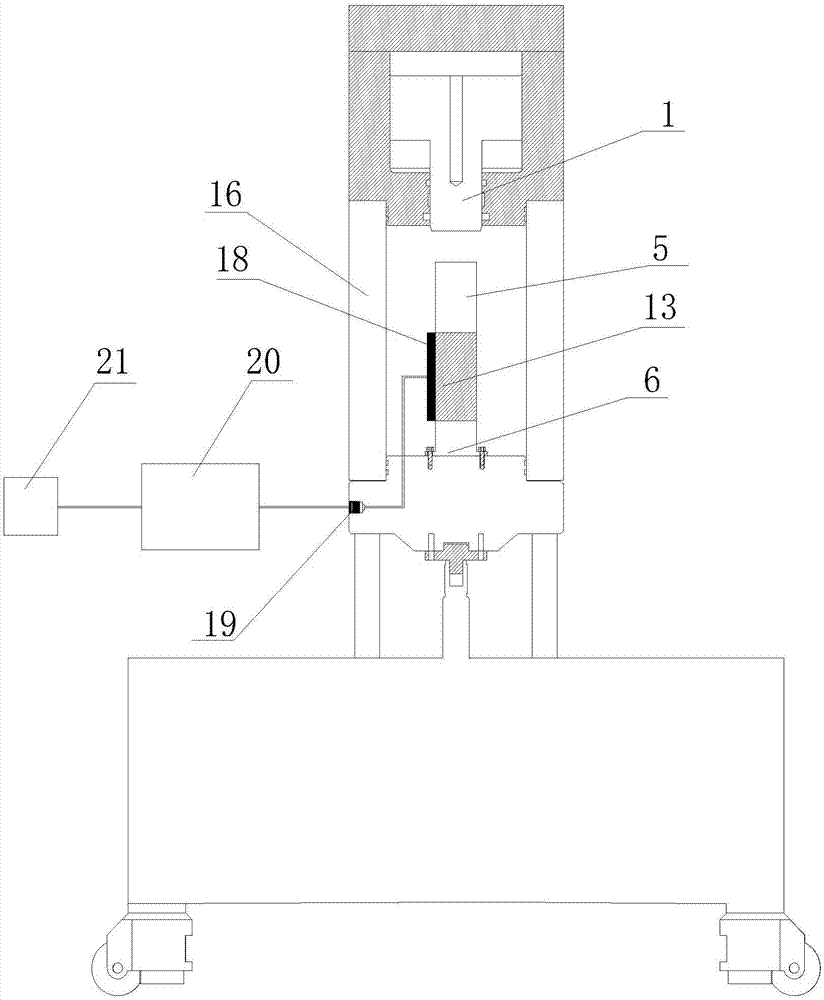

[0024] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

[0025] Referring to the accompanying drawings, it can be seen that the rock true triaxial test method with an ultrasonic phased array real-time imaging system is characterized in that it includes the following steps:

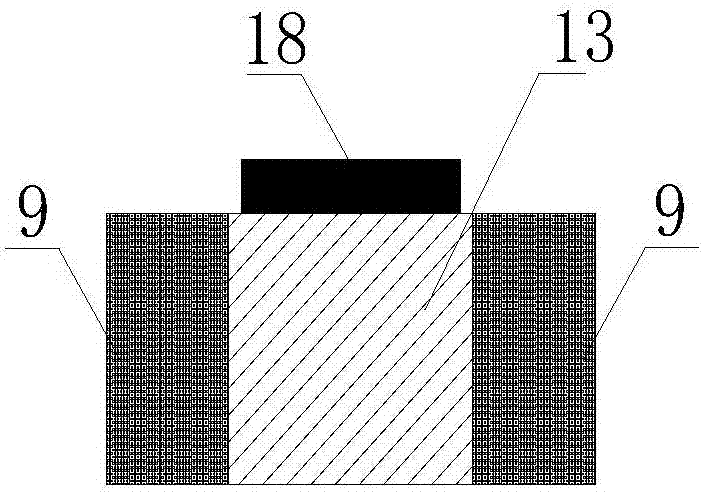

[0026] Step 1: Place the sample 13 between the square upper indenter 5 in the confining pressure chamber 16 and the square lower indenter 6 in the confining pressure chamber 16, and use rubber sleeves to place the sample 13 and the square upper indenter 5 And the square lower pressure head 6 sets, and the rubber sleeve is sealed with a clamp; a base 17 is arranged below the confining pressure chamber 16; the acoustic wave emi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com