Continuously adjustable throttle valve

A throttling valve and flow adjustment technology, which is applied in valve details, diaphragm valves, valve devices, etc., can solve the problems of inability to accurately control the flow rate, shorten the practical life, sudden changes in flow rate and pressure difference, etc., to ensure that The effect of using, ensuring fluency, and ensuring the effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

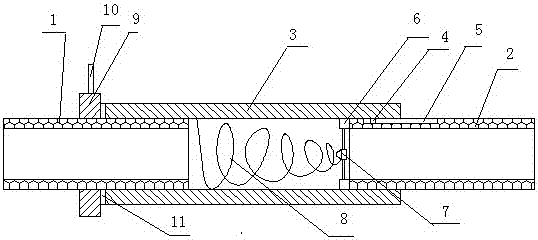

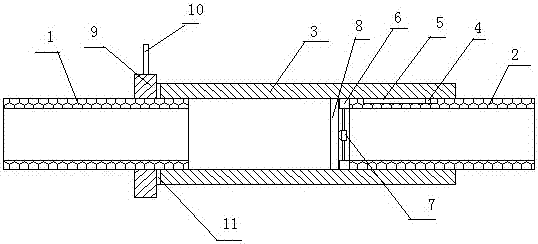

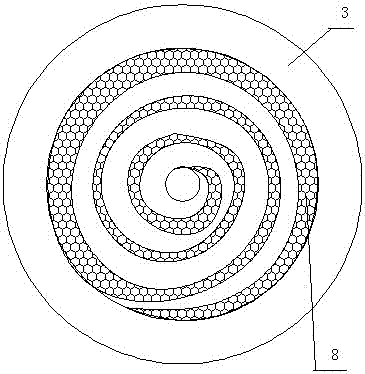

[0015] Below in conjunction with accompanying drawing, the present invention is further described:

[0016] As shown in the attached figure, a continuously adjustable throttle valve is provided with a water inlet pipe 1 and a water outlet pipe 2. The two ends of the pipe 3 are socketed on the outside of the water inlet pipe 1 and the water outlet pipe 2 with a slight gap. The inner pipe wall connecting the flow regulating pipe 3 and the water outlet pipe 2 is provided with a sliding table 4. The water outlet pipe 2 is provided with a chute 5 matched with the slide table 4, and the two ends of the chute 5 are respectively closed, and the flow regulating pipe 3 slides on the water inlet pipe 1 and the water outlet pipe 2 through the slide table 4 and the chute 5. The end of the water outlet pipe 2 is provided with a baffle, and the baffle is composed of a ring piece 6 and a center piece 7, the ring piece 6 is connected with the center piece 7 through a pole, and the center piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com