Composite sulfur-fixing agent for coal combustion, composite sulfur-fixing coal-water slurry and sulfur-fixing method in furnace with burning

A composite, coal-water slurry technology, applied in the field of desulfurization, can solve the problems of low sulfur fixation efficiency, unsatisfactory ultra-low and ultra-clean emissions, and difficult utilization of desulfurization products, achieving low cost, low transportation costs, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Grinding limestone to prepare fine calcium carbonate: get calcium carbonate content 95%, particle diameter 1cm bulk limestone, drop in the dragon roller mill, grind 10min, measure the specific surface area of the grinding product by Blaine's specific surface area meter, convert to Particle size (mm), so that the particle size is less than or equal to 5 microns, and the particle size changes with the grinding time as attached figure 1 .

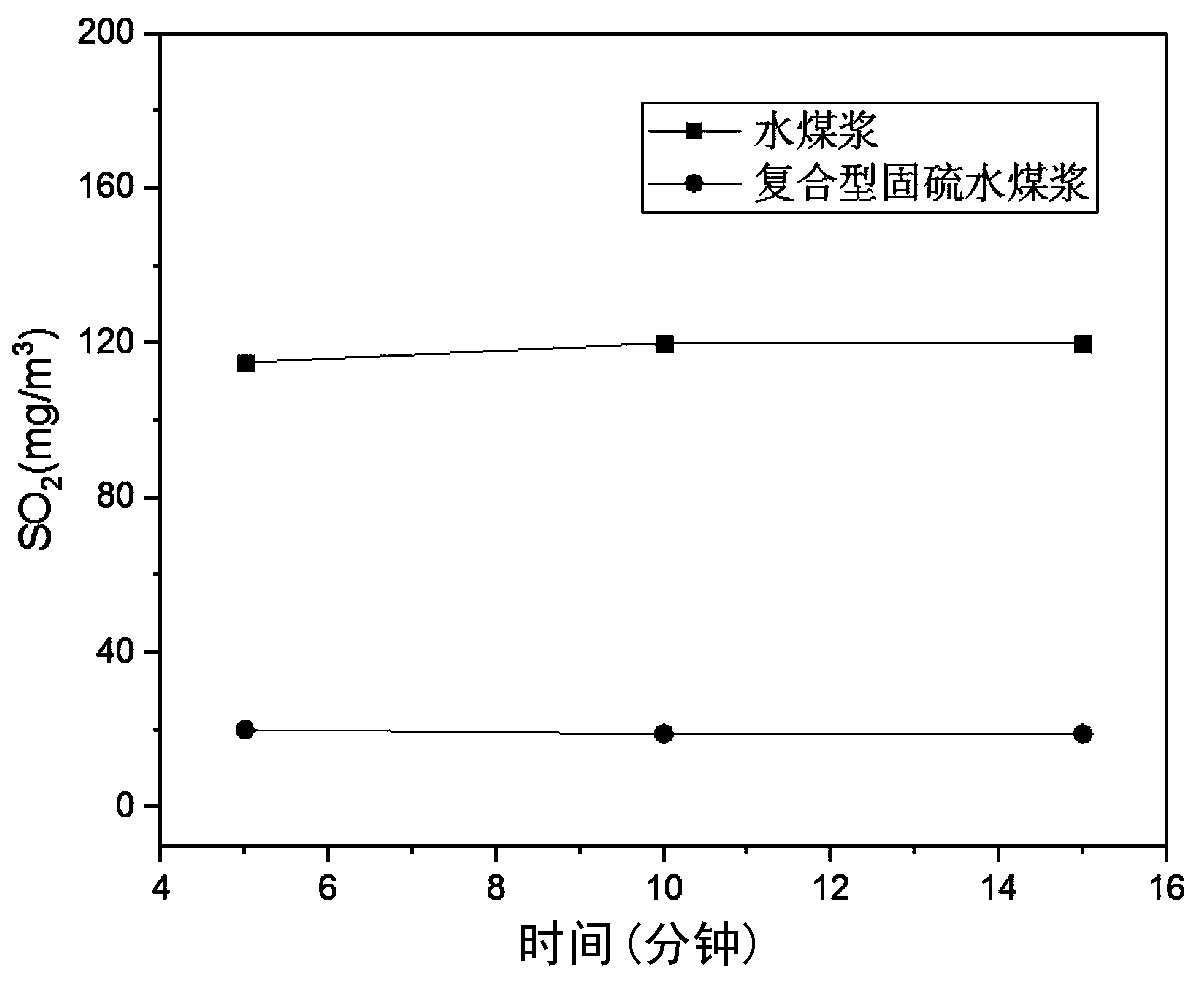

[0053] (2) Mix fine calcium carbonate with coal water slurry according to different ratios of calcium and sulfur to make sulfur-fixing type coal water slurry: measure the total sulfur of coal water slurry according to the national standard GB / T214-2007 "Determination of total sulfur in coal" by Coulomb method content, the total sulfur content in this example is 0.5%, according to the calcium-sulfur molar ratio of 1.5:1, add the fine calcium carbonate prepared in Example 1 into the coal-water slurry, stir with a mixer at a speed of...

Embodiment 2

[0063] (1) Grinding limestone to prepare fine calcium carbonate: get calcium carbonate content 95%, particle diameter 1cm bulk limestone, drop in the dragon roller mill, grind 10min, measure the specific surface area of the grinding product by Blaine's specific surface area meter, convert to Particle size (mm), such that the particle size is less than or equal to 5 microns.

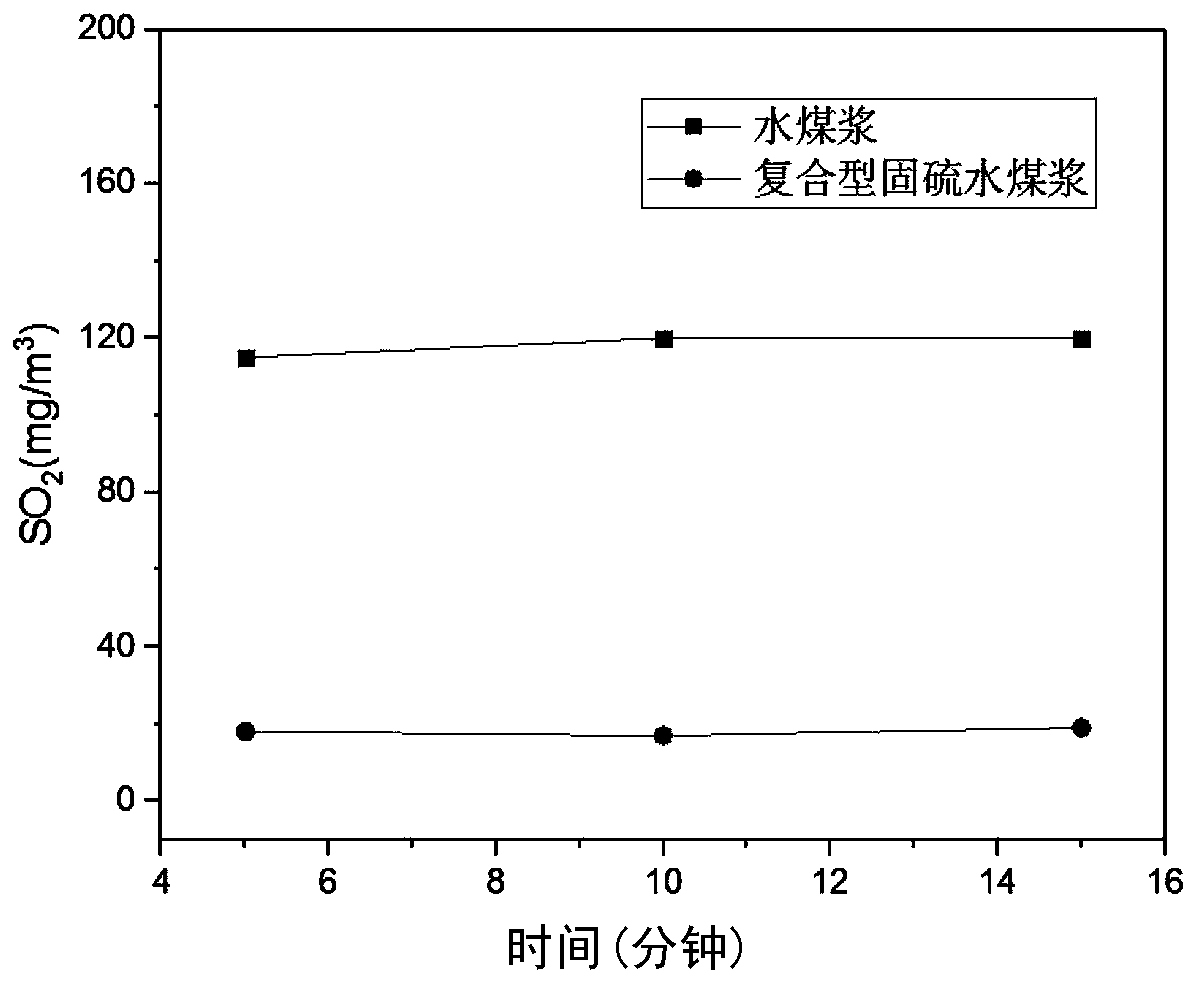

[0064] (2) Mix fine calcium carbonate with coal water slurry according to different ratios of calcium and sulfur to make sulfur-fixing type coal water slurry: measure the total sulfur of coal water slurry according to the national standard GB / T214-2007 "Determination of total sulfur in coal" by Coulomb method content, the total sulfur content in this example is 0.5%, according to the calcium-sulfur molar ratio of 2.0:1, add the fine calcium carbonate prepared in Example 2 (1) into the coal-water slurry, stir with a mixer at a speed of 500 rpm for 10 minutes and mix uniform.

[0065] (3) Preparation of ...

Embodiment 3

[0074] (1) Grinding limestone to prepare fine calcium carbonate: get calcium carbonate content 95%, particle diameter 1cm bulk limestone, drop in the dragon roller mill, grind 10min, measure the specific surface area of the grinding product by Blaine's specific surface area meter, convert to Particle size (mm), make the particle size less than or equal to 5 microns.

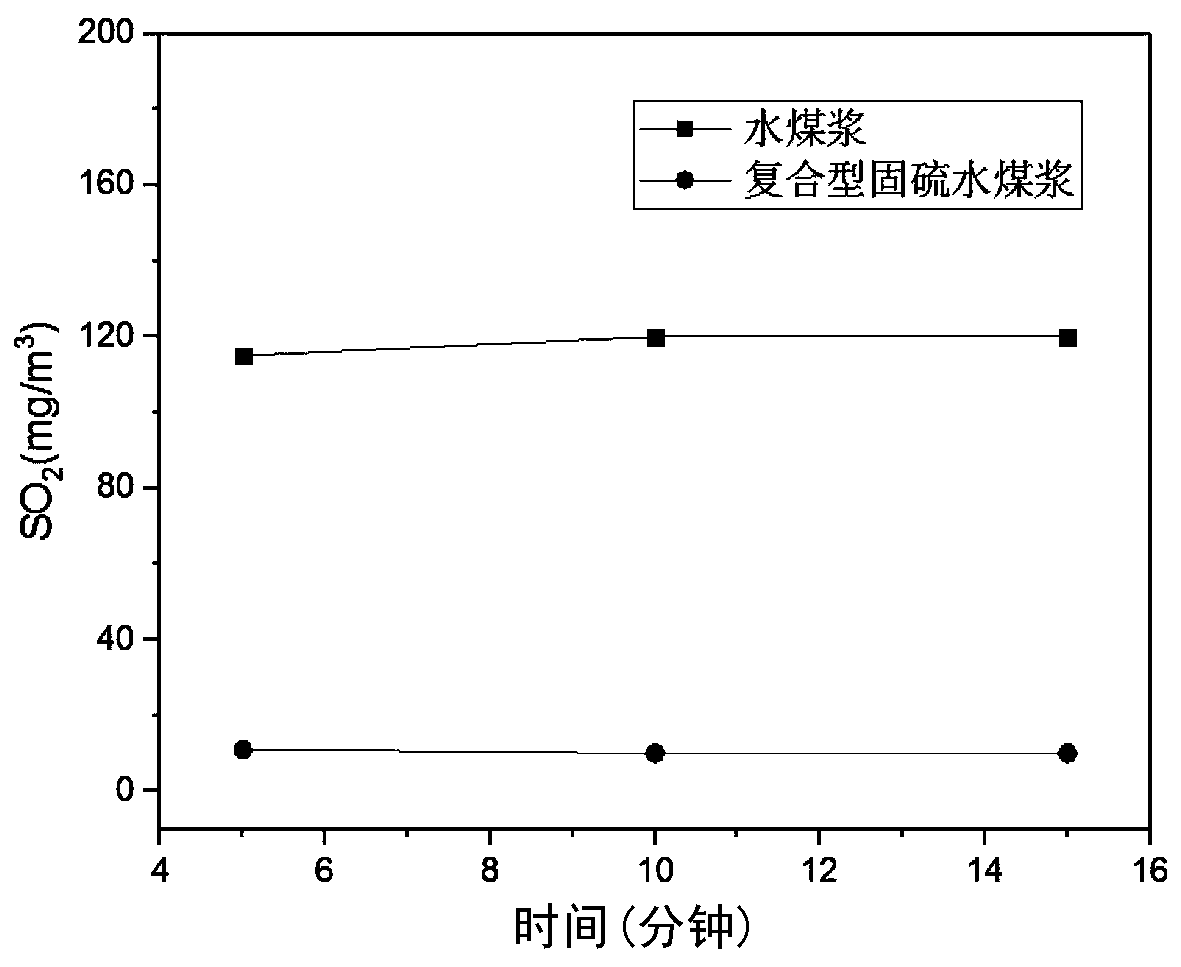

[0075] (2) Mix fine calcium carbonate with coal water slurry according to different ratios of calcium and sulfur to make sulfur-fixing type coal water slurry: measure the total sulfur of coal water slurry according to the national standard GB / T214-2007 "Determination of total sulfur in coal" by Coulomb method content, the total sulfur content in this example is 0.5%, according to the calcium-sulfur molar ratio of 1.5:1, add the fine calcium carbonate prepared in Example 3 (1) into the coal-water slurry, stir with a mixer at a speed of 500 rpm for 10 minutes and mix uniform.

[0076] (3) Preparation of fine sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com