Front paper beating device used for stacking by stacking machine

A stacking machine and stacking technology, which is applied in the field of the front-mounted paper device for stacking machine stacking, can solve the problems of reducing production efficiency, increasing production costs, and prone to paper jams, so as to improve production efficiency and save production cost, and the effect of reducing back-end processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

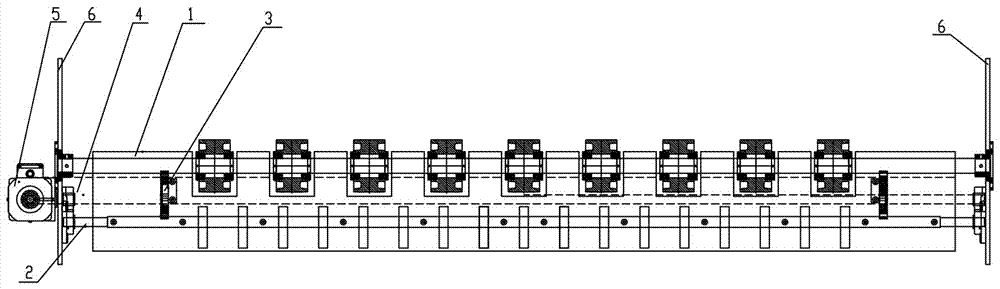

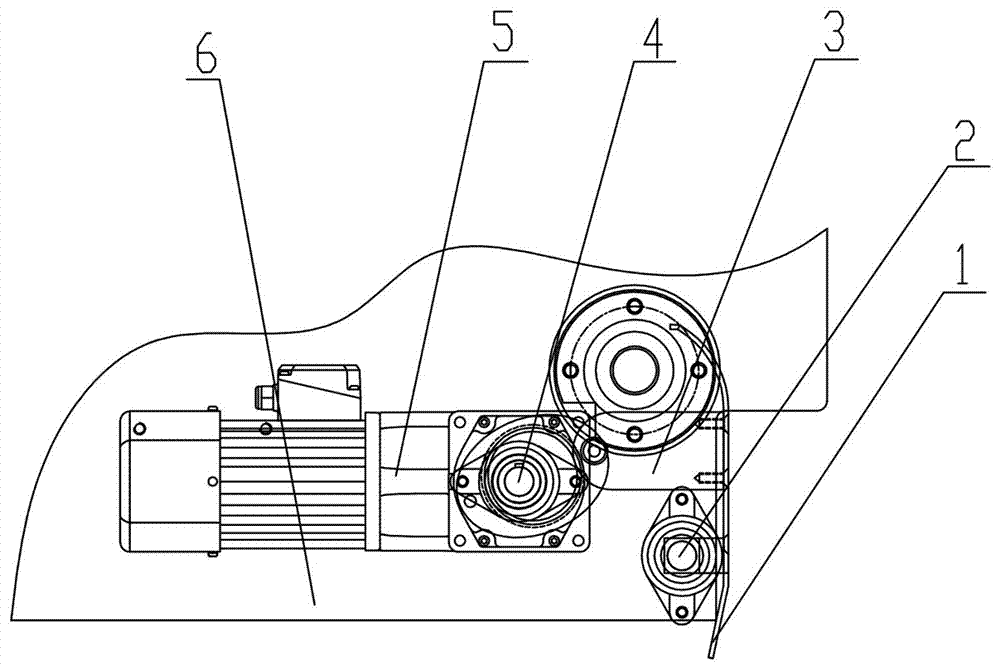

[0019] Such as Figure 1 to Figure 5 As shown in the figure, a front-mounted paper device for stacking in a stacker includes a paddle 1, a swing lever 2 supporting the paddle 1, and an eccentric mechanism 3 connected to the paddle 1. The eccentric mechanism 3 communicates with the motor through an eccentric transmission shaft 4. The reducer 5 is connected, the clapper board 1 is installed on the swing rod 2, the upper part of the clapper board 1 is an arc structure, and the lower part of the clapper board 1 is a bent structure; On the support frame 6 , the eccentric mechanism 3 is installed on the eccentric transmission shaft 4 and connected with the paddle 1 .

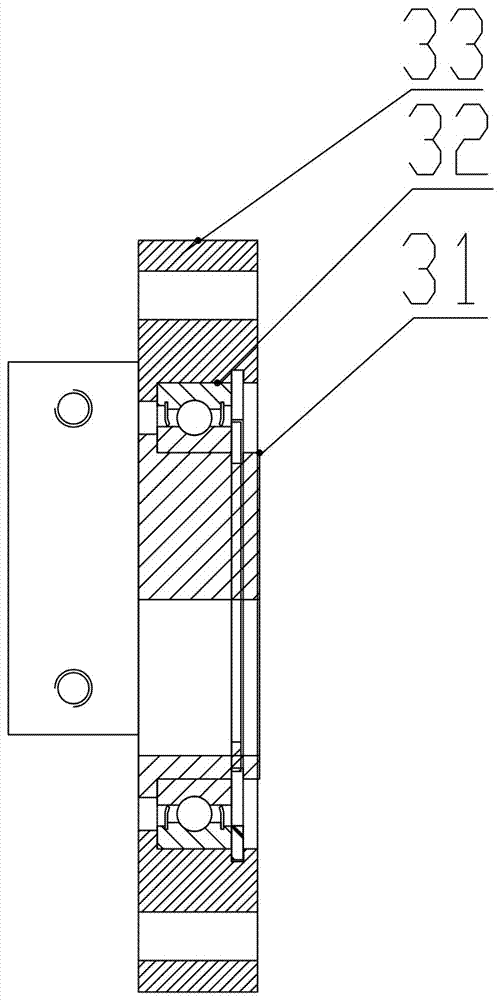

[0020] In this embodiment, the eccentric mechanism 3 includes a paper eccentric sleeve 31, a bearing A32, a paper bearing sleeve 33, a paper rocker seat 34, a bearing B35 and a paper eccentric pin 36, and the inner ring of the bearing A32 is eccentrically aligned with the paper. The sleeve 31 cooperates, the outer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com