Steel ball assembling structure used for sliding rail assembly of automobile seat

A car seat slide rail and assembly structure technology, which is applied to vehicle seats, movable seats, vehicle parts, etc., can solve the problems of damage to the quality of inner slide rail components, low assembly efficiency, and high labor costs. The assembly operation is simple and easy, the assembly efficiency is improved, and the labor cost is saved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

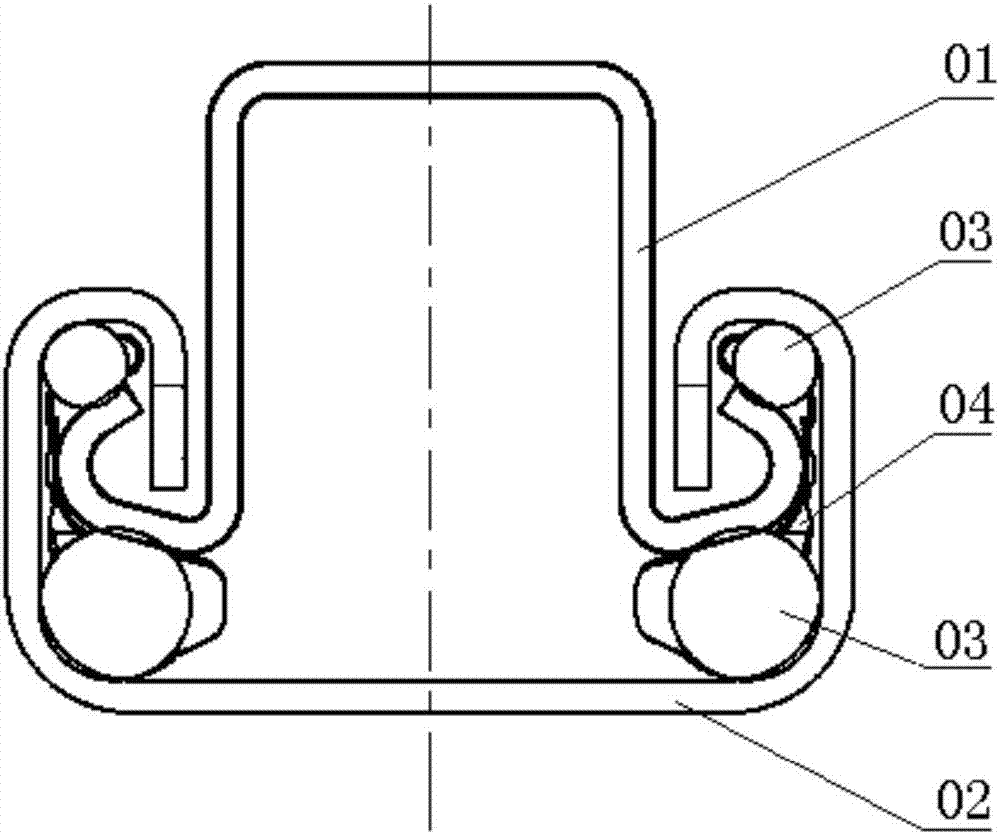

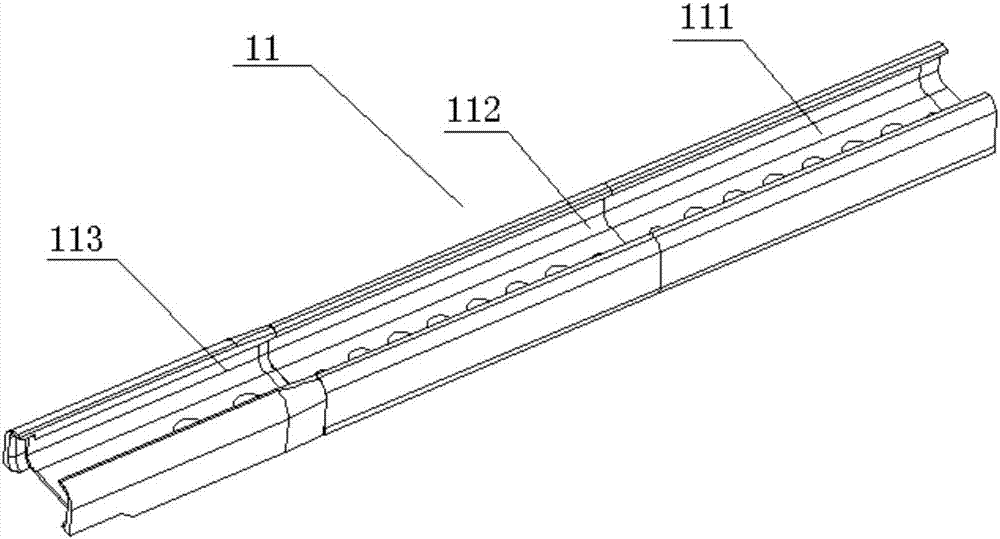

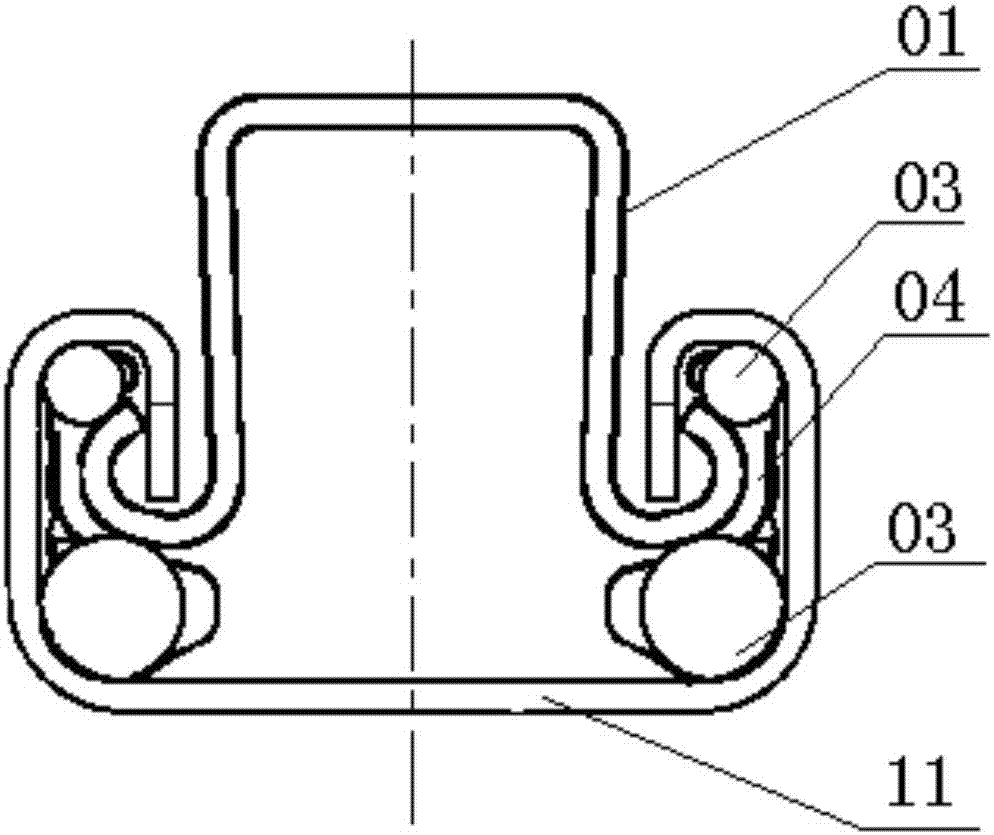

[0035] Please refer to Figure 2-Figure 3 , figure 2 A structural schematic diagram of a specific embodiment of the simulated outer slide rail of the steel ball assembly structure provided by the present invention; image 3 For inner slides, balls and ball cages figure 2 In the state of simulating the outer slide rail shown, the schematic diagram of the inner slide rail being pressed against the opening by the simulated outer slide rail.

[0036] like figure 2 As shown, the steel ball assembly structure for the car seat slide rail assembly provided by the present invention includes a simulated outer slide rail 11, which is used to cooperate with the inner slide rail 01. In the mated state, a receiving place is forme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap