Classifying device used after fine crushing of waste metal and classifying method for classifying device

A technology for scrap metal and sorting device, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problem of time-consuming and laborious manual sorting, and achieve the effect of reducing secondary adsorption, clear sorting and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

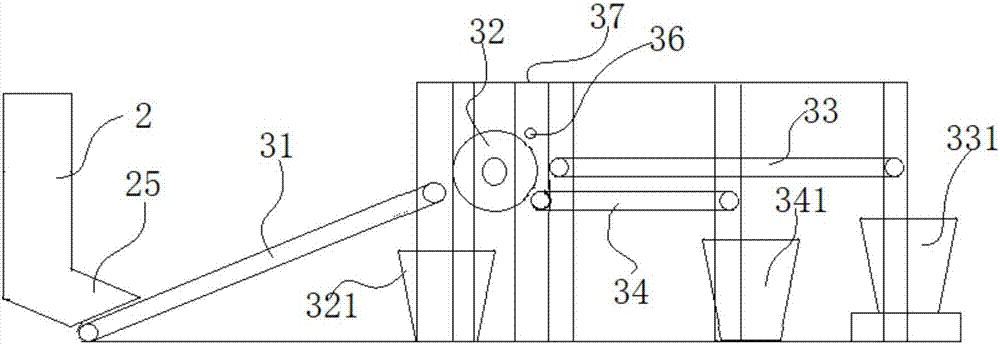

[0039] A sorting device after fine crushing treatment of scrap metal, such as figure 1 As shown, it includes a frame-shaped fixed frame 37 and a magnetic roller 32 fixed on the fixed frame 37 through bearings. The two sides of the cylinder surface of the magnetic roller 32 are provided with a feeding conveyor belt 31 and an output conveyor belt respectively fixed on the fixed frame 37. Material conveyor belt; wherein: the end of the feeding conveyor belt 31 is close to one side of the magnetic drum 32, and there is a blanking gap for non-ferrous materials; the beginning of the discharge conveyor belt is infinitely close to the other side of the magnetic drum 32. , can be close to the drum surface, such as 1 mm apart between the two, to facilitate the interception of the absorbed iron material;

[0040] In the specific application of the waste metal finely crushed classification device in this embodiment, the metal crusher 2 drops the crushed material to the feeding conveyor be...

Embodiment 2

[0042]The waste metal finely crushed sorting device of this embodiment has the same basic structure as that of Embodiment 1, and the improvement is that: there are two discharge conveyor belts, which are arranged in parallel up and down, and the upper and lower sides are respectively a large-grain iron material conveyor belt 33 and a small-grain iron material conveyor belt. Conveyor belt 34; the cylinder surface of described large grain iron material conveyer belt 33 and magnetic cylinder 32 reserves a gap, in the present embodiment, the gap size is 15mm; Described small grain iron material conveyer belt 34 is infinitely close to the cylinder surface of magnetic cylinder 32, can Close to the cylinder surface, for example, the distance between the two is less than 1mm.

[0043] In the specific application of the classification device after fine crushing treatment of scrap metal in this embodiment, on the basis of dividing the crushed material into iron material with a specificat...

Embodiment 3

[0046] The waste metal finely crushed sorting device of this embodiment has the same basic structure as that of Embodiment 2, and the improvement is that the conveying speed of the discharge conveyor belt is greater than the feeding speed of the feeding conveyor belt 31, and the advantage is that the iron material after adsorption can be absorbed. After the large-particle iron material conveyor belt 33 and the small-particle iron material conveyor belt 34 are respectively intercepted, they are transferred as soon as possible to reduce the secondary adsorption of the iron material and avoid accumulation at the junction due to the secondary adsorption as much as possible. A non-ferrous material collection box 321 is arranged at the bottom of the non-ferrous material blanking gap, and a large-particle iron material collection box 331 and a small-particle iron material collection box 331 are respectively arranged at the ends of the large-particle iron material conveyor belt 33 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com