Extrusion die for biomass fuel

A biomass fuel and extrusion die technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of affecting the combustion effect of biomass fuel particles, increasing the production cost of biomass fuel, and high density of biomass fuel, etc., to achieve Improve the scope of use, save manpower and material resources, and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

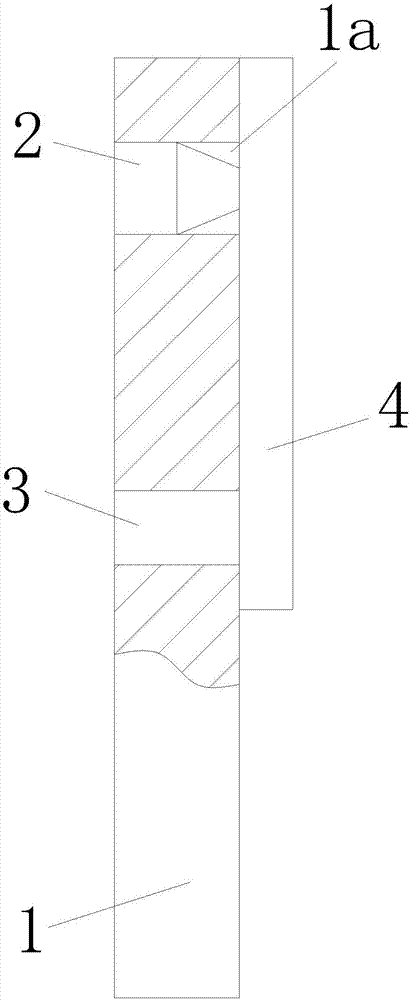

[0024] Such as Figure 1 to Figure 2 As shown, a kind of extrusion die for biomass fuel comprises a positioning head 1, and several through holes 1a are arranged on the positioning head 1, and a granulation unit 2 is installed in a detachable manner in the through holes 1a, and the positioning head 1 Also be installed with rotating shaft 3 on the rotating shaft 3, segment cutter 4 is installed on the rotating shaft 3, rotating shaft 3 is connected with positioning shaft. When in use, the rotating shaft 3 is connected with an external power source, and the external power source drives the rotating shaft 3 to rotate, and the rotating shaft 3 drives the segmented knife 4 to rotate, cutting off the long strip of biomass fuel to form particles, replacing the traditional through The method of self-weight forming, and the granulation unit 2 of different specifications can be replaced according to different types of biomass fuels, which improves the use range of the device, is conveni...

Embodiment 2

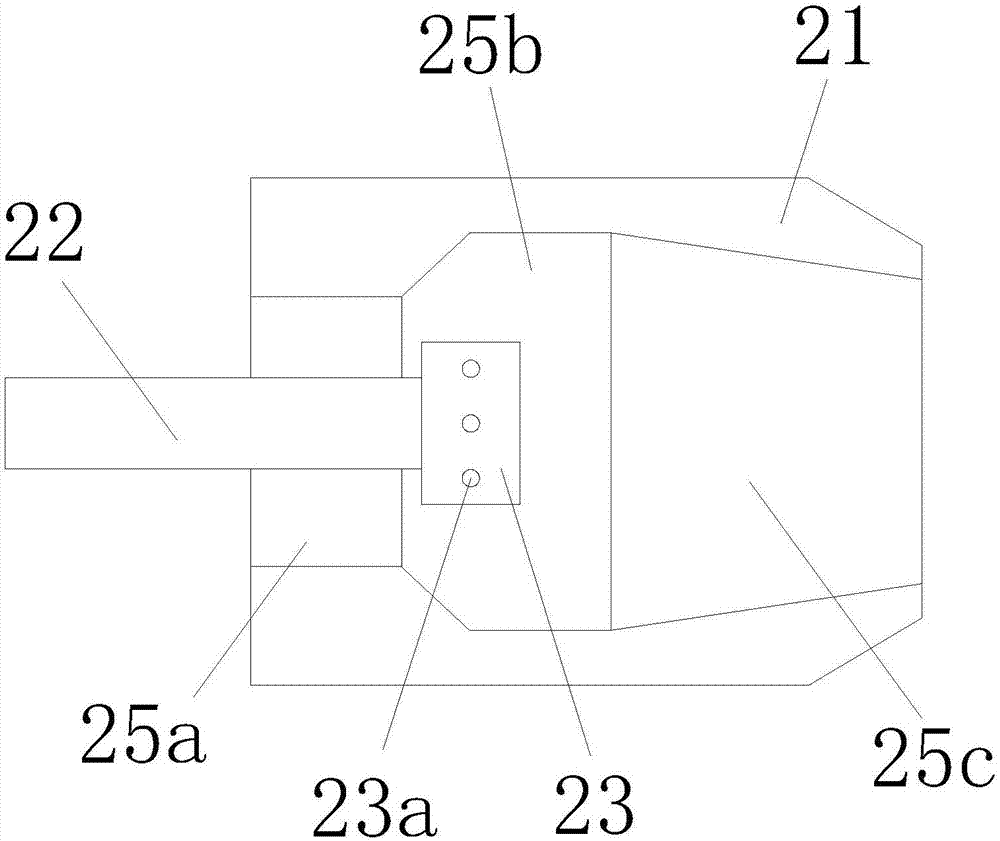

[0033] Such as image 3 As shown, the difference from Embodiment 1 is that the gas filling head 23 is arranged in the material introduction cavity 25a, which can accelerate the flow velocity of the biomass fuel to form an uneven The air bubbles increase the combustion efficiency of biomass fuel.

Embodiment 3

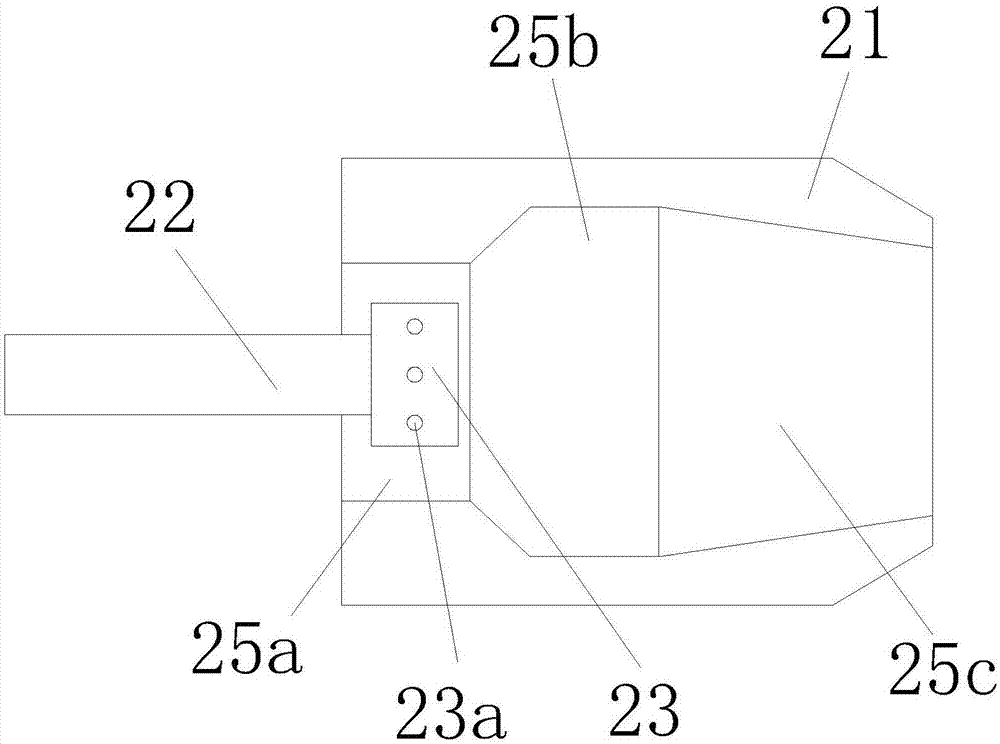

[0035] Such as Figure 4 As shown, the difference from Embodiment 1 is that the gas filling head 23 is a hemispherical gas filling head, which can make the biomass fuel form smaller holes during the extrusion process, thereby reducing the The amount of deformation ensures the structural strength of the biomass fuel.

[0036] When in use, the biomass fuel enters the molding channel on the mold cavity 21 through extrusion, and the biomass fuel passes through the conduit 22 to form a hollow structure, and in the process, the external gas source works to send the gas into the conduit 22, and the gas passes through The gas filling head 23 on the conduit 22 physically fills the biomass fuel in the mold cavity 21, so that holes are formed in the hollow structure of the biomass fuel, and the natural foaming of the biomass fuel is realized. At the same time, the external power source works, and the power source Drive the rotating shaft 3 to rotate, and the rotating shaft 3 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com