Spray dryer

A spray dryer and drying tower technology, which is applied in spray evaporation, evaporator adjustment/control, evaporator accessories, etc., can solve the problem of inability to actively adjust the material particle size and material collection ratio relationship, and the material collector cannot quantitatively collect materials. Problems such as troublesome material collection, to achieve the effect of convenient and fast adjustment, avoid weighing and packaging, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

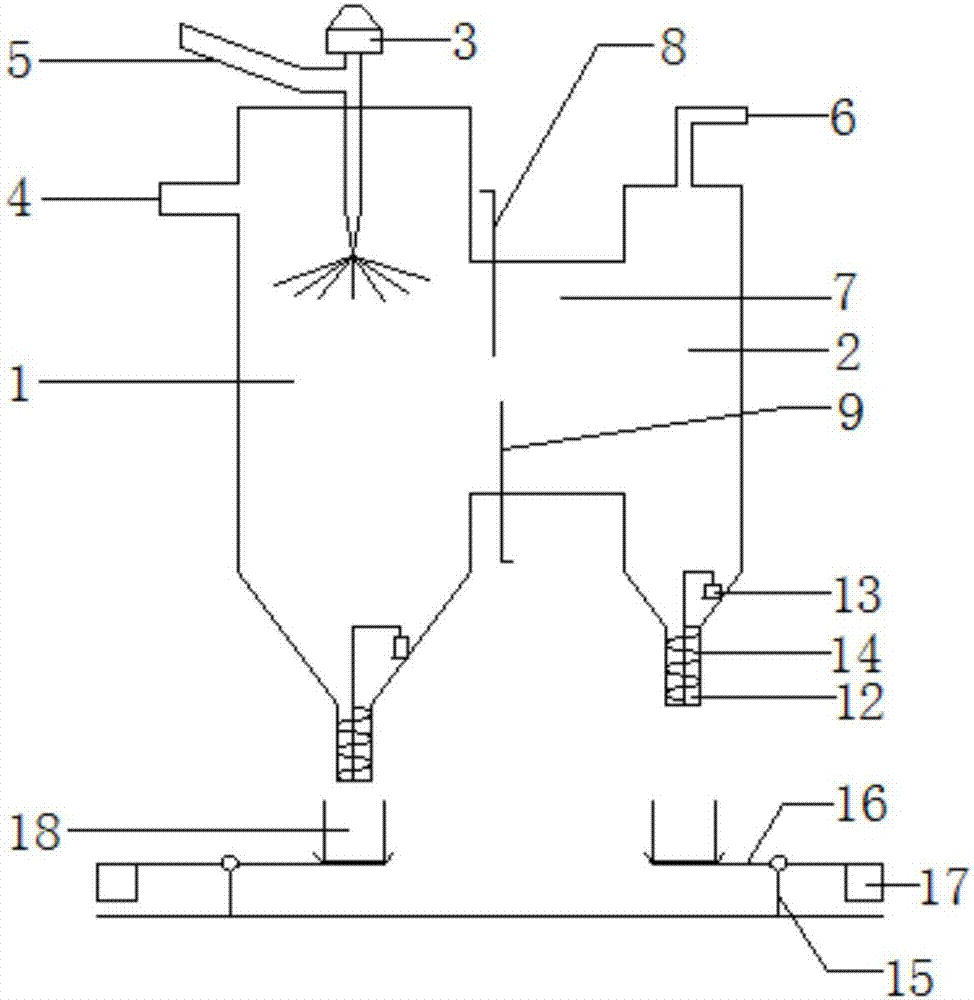

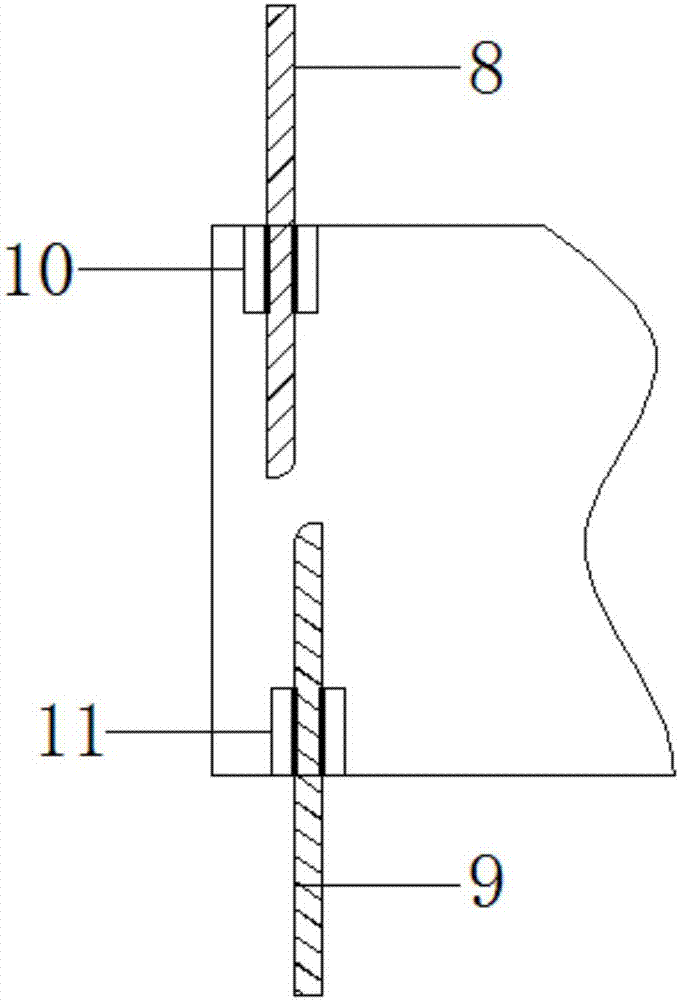

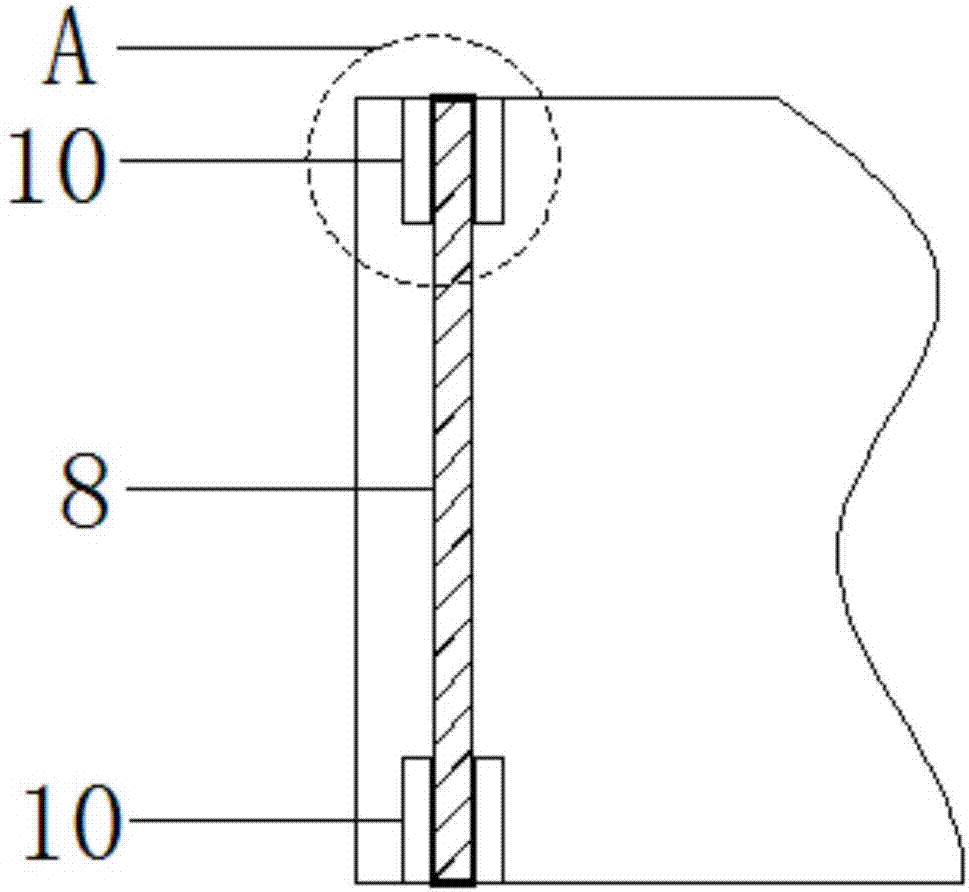

[0034] Such as Figure 1-Figure 8As shown, in order to achieve the above object, the technical solution adopted in the present invention is: a spray dryer, comprising a drying tower 1, a cyclone separator 2, a high-speed centrifugal atomizer 3; the top of the drying tower 1 is provided with a hot air inlet 4 After the high-speed centrifugal atomizer 3 passes through the top center of the drying tower 1, the nozzle of the high-speed centrifugal atomizer 3 is located at the top of the drying tower 1, and the high-speed centrifugal atomizer 3 is the same as the drying tower 1 The axis is set, the high-speed centrifugal atomizer 3 is provided with a feed inlet 5, and the top of the cyclone separator 2 is provided with an air outlet 6; the side wall of the drying tower 1 and the side wall of the cyclone separator 2 The side wall is provided with a chamber 7 communicated in the vertical direction, the chamber 7 is provided with a first dividing plate 8 vertically inserted into the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com