Garlic mashing device

A technology of carrying device and storage device, which is applied in the field of kitchen supplies, and can solve the problems of manpower consumption, garlic splashing, garlic cloves being difficult to be muddy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

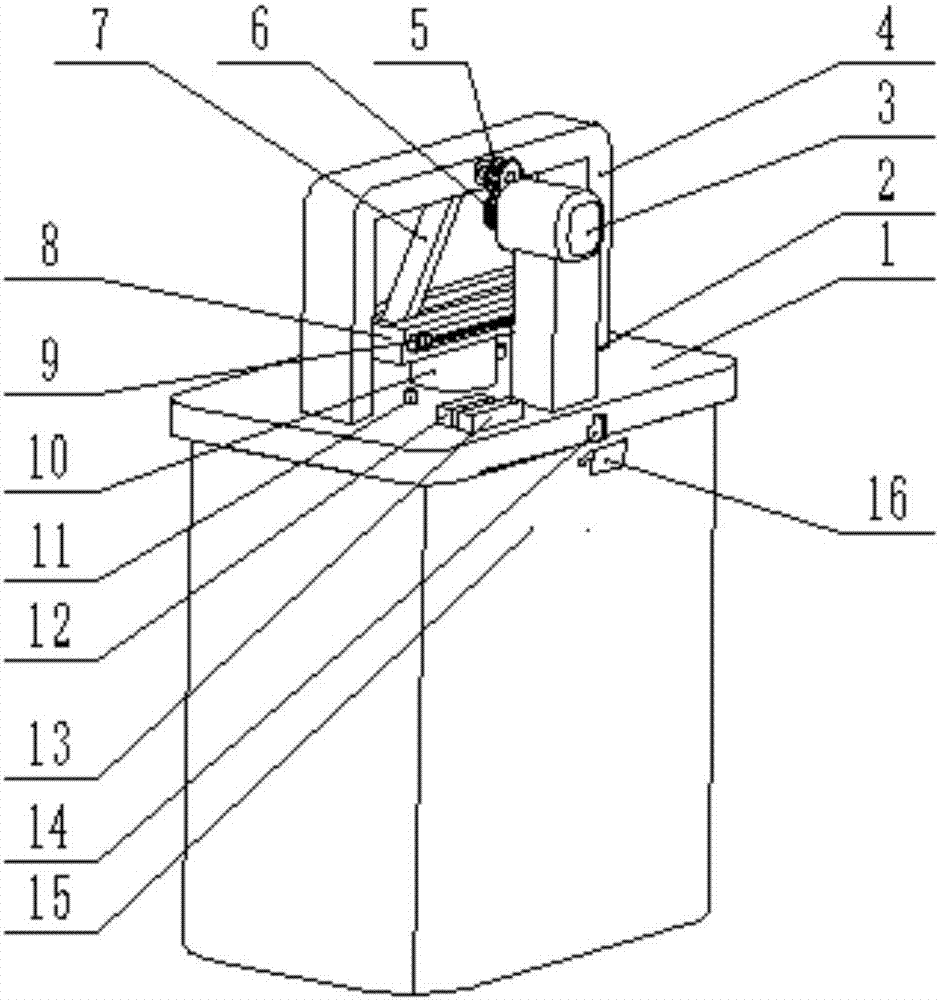

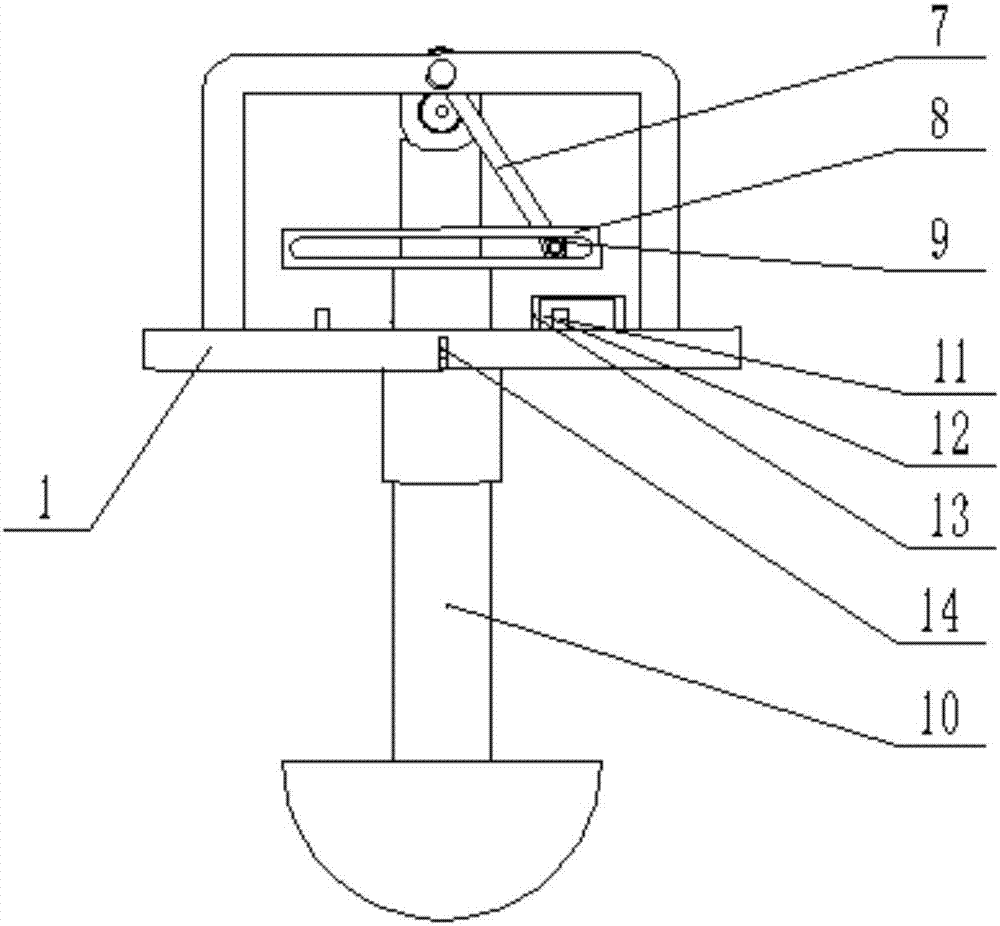

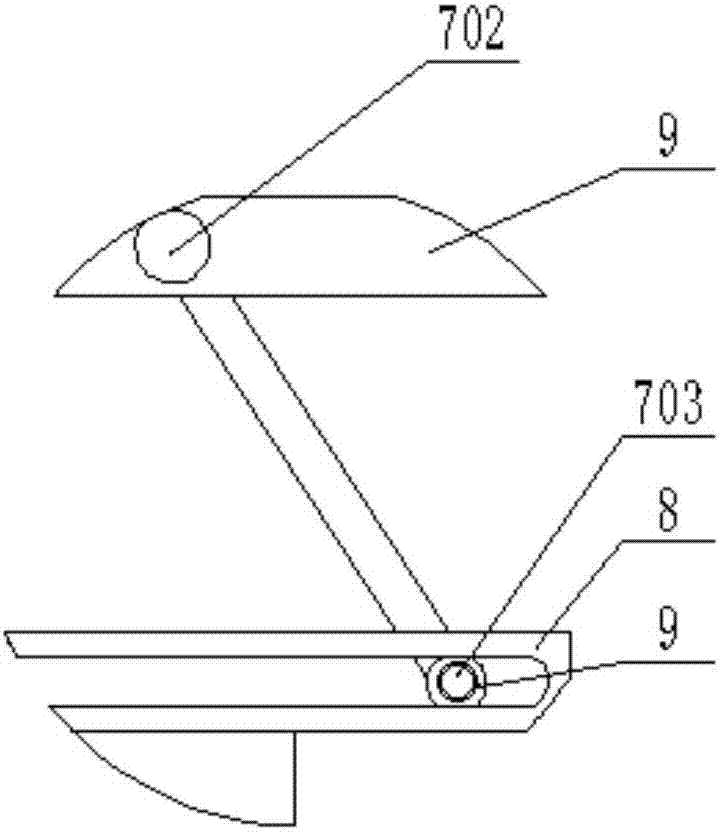

[0021] A mashed garlic device is composed of a bearing device, a motion mechanism, a control part, a power unit and a storage device. The bearing device is composed of a bearing platform 1, a motor frame 2, and a rocker hanger 4, wherein the motor frame On the upper side of the bearing platform 1, the rocker hanger 4 is located directly above the bearing platform 1. The rocker swing groove 402 and the rocker installation through hole 401 are opened on the rocker hanger 4. The rocker installation hole 401 is located on the rocker hanger. 4. The center of the beam; the motion mechanism is composed of a rocker 7, a rocker chute 8, a drum 9, and a garlic hammer 10, and the garlic hammer 10 passes through the through hole 101 of the garlic hammer stroke on the carrying platform 1 and the rocker The rod chute 8 is fastened with bolts, the connection position is that the threaded hole 1001 on the garlic hammer 10 and the stepped hole 801 on the rocker chute 8 are arranged concentrical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com