Ground contactor based on infrared sterilization system

A technology of a sterilization system and a contactor, which is applied to shoe soles, applications, footwear, etc., can solve the problems of being unsuitable for large-scale production, high cost, low cost, etc., and achieve the effects of low production cost, simple structure, and improved general performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

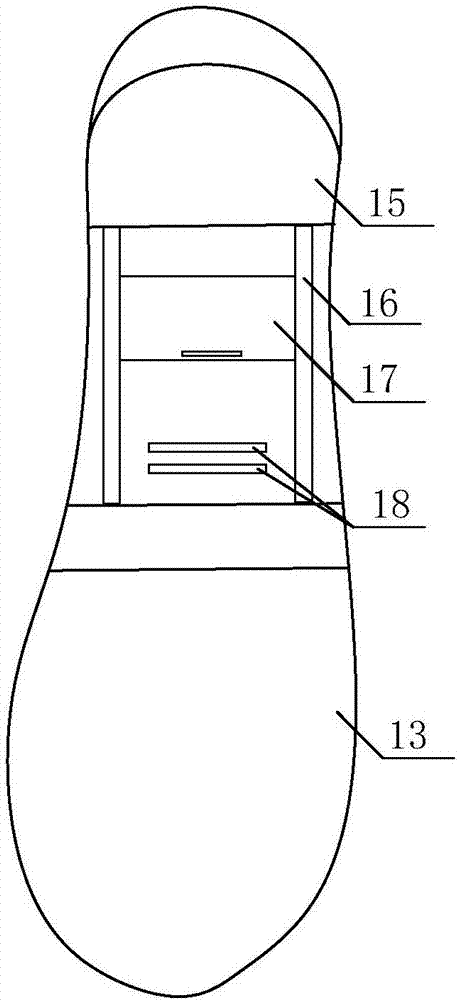

[0025] Ground contactors based on infrared sterilization systems such as Figure 1-Figure 2 As shown, the sole 1 comprising a high sole, and the vamp 2 arranged on the sole 1; the sole 1 comprises a midsole 11, a waterproof platform 12 arranged at the position in front of the midsole 11, and a waterproof platform 12 arranged at the bottom of the waterproof platform 12 The outsole 13, the heel 14 arranged at the rear position of the midsole 11, and the sky skin 15 arranged at the bottom of the heel 14.

[0026] The waist position of the midsole 11 is provided with an air vent 18 that runs through the midsole 11, and fixed chute 16 is provided on both sides of the bottom surface of the midsole 11 below the air vent 18, and the fixed chute 16 is also provided with a useful It is used to block the sliding baffle plate 17 of the ventilation hole 18.

[0027] The ventilation holes 18 are long strips, the length is 1 / 2-2 / 3 of the width of the midsole 11, and the width is 2-5 mm.

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is that the structure of the air vent 18, the fixed chute 16 and the sliding baffle 17 is optimized, and the specific settings are as follows:

[0030] The number of the air holes 18 is two, and the width of each air hole 18 is 2-3 mm. The fixed sliding groove 16 is composed of two symmetrical concave parts opposite to each other in the opening direction. The concave part is made of stainless steel.

[0031] The bottom end of the midsole 11 is provided with a groove, and the fixed sliding groove 16 is installed in the groove. The sliding baffle 17 is provided with a protrusion that is convenient for manually moving the position of the sliding baffle 17 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com