Preparation process of bean paste containing tartary buckwheat polysaccharide

A production process, the technology of bean paste, which is applied in the direction of polysaccharide/gum-containing food ingredients, food ingredients as taste improvers, and the function of food ingredients, etc., can solve the problems of potential safety hazards, high content of biogenic amines in bean paste, and achieve prevention of constipation, Effects of avoiding food safety hazards and treating obesity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

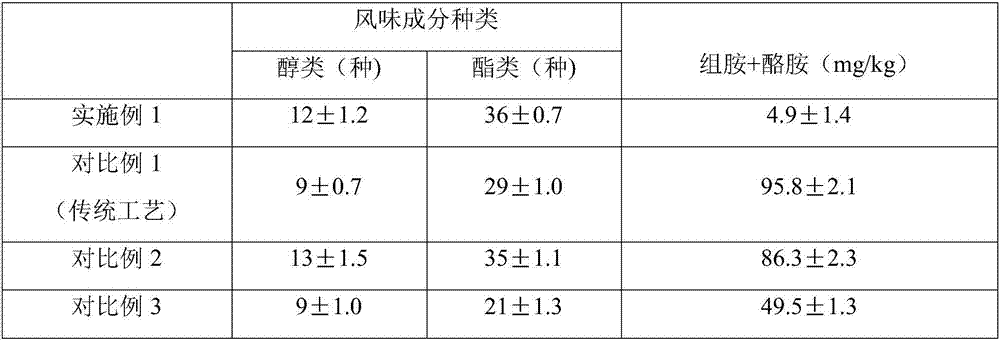

Examples

Embodiment 1

[0022] (1) Preparation of short-chain tartary buckwheat polysaccharide

[0023] Choose 1.0kg tartary buckwheat skin powder as raw material and extract with 5.0L water. The extract was then precipitated with 20L of absolute ethanol to obtain crude tartary buckwheat polysaccharide, which was further separated by glucose gel G-25, collected tartary buckwheat polysaccharide fractions with a DP range of 5-10, and dried to obtain 135g tartary buckwheat short-chain polysaccharide. Detected by the laser scattering detector, the distribution range of more than 90% DP is 5-8.

[0024] (2) Homogeneous raw materials

[0025] Choose 1.0kg traditional Pixian Douban as the raw material, add 1.0L of water, and carry out ultra-fine crushing, so that more than 90% of the bean paste can be passed through a 100-mesh steel wire sieve, filtered, and homogenized by a high-shear homogenizer to obtain 1.75kg Bean sauce ingredients.

[0026] (2) Add tartary buckwheat polysaccharide

[0027] Add 70 g of tartar...

Embodiment 2

[0031] (1) Preparation of short-chain tartary buckwheat polysaccharide

[0032] Choose 1.0kg tartary buckwheat skin powder as raw material, and extract with 4.0L water. The extract was then precipitated with 20L of absolute ethanol to obtain crude tartary buckwheat polysaccharides, which were further separated by a glucose gel G-25 column to collect tartary buckwheat polysaccharides with a DP range of 5-10. After drying, 120g tartary buckwheat short-chain polysaccharides were obtained. . Detected by laser scattering detector, the distribution range of DP over 90% is 6-9.

[0033] (2) Homogeneous raw materials

[0034] Choose 1.0kg of traditional Pixian Douban as the raw material, add 1.0L of water, and carry out ultra-fine pulverization, so that more than 90% of the bean paste can pass through a 100-mesh steel wire sieve and homogenized by a high-shear homogenizer to obtain 1.75kg of bean paste raw material.

[0035] (3) Add short-chain tartary buckwheat polysaccharide

[0036] 52.5...

Embodiment 3

[0040] (1) Preparation of short-chain tartary buckwheat polysaccharide

[0041] Choose 1.0kg tartary buckwheat skin powder as raw material and extract with 6.0L water. The extract was then precipitated with 18L of absolute ethanol to obtain crude tartary buckwheat polysaccharide, which was further separated by a glucose gel G-25 column to collect DP <10 short-chain polysaccharide fraction, after drying, 184g of tartary buckwheat short-chain polysaccharide is obtained. Detected by laser scattering detector, the distribution range of DP over 90% is 3-10.

[0042] (2) Homogeneous raw materials

[0043] Choose 1.0 kg of traditional Pixian Douban Douban as raw material, add 1.0L of water, carry out ultra-fine pulverization, filtration, and homogenize through a high-shear homogenizer to obtain 1.75 kg of Douban paste raw materials.

[0044] (2) Add tartary buckwheat polysaccharide

[0045] Add 87.5 g of tartary buckwheat polysaccharide with a DP value of 3-10 to the bean paste raw material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com