A kind of quick fermentation method of Liubao tea

A fermentation method and technology for Liubao tea, applied in the field of rapid fermentation of Liubao tea, can solve problems such as restricting the development and growth of Liubao tea industry, unstable tea quality, long time period, etc. The effect of shortening the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

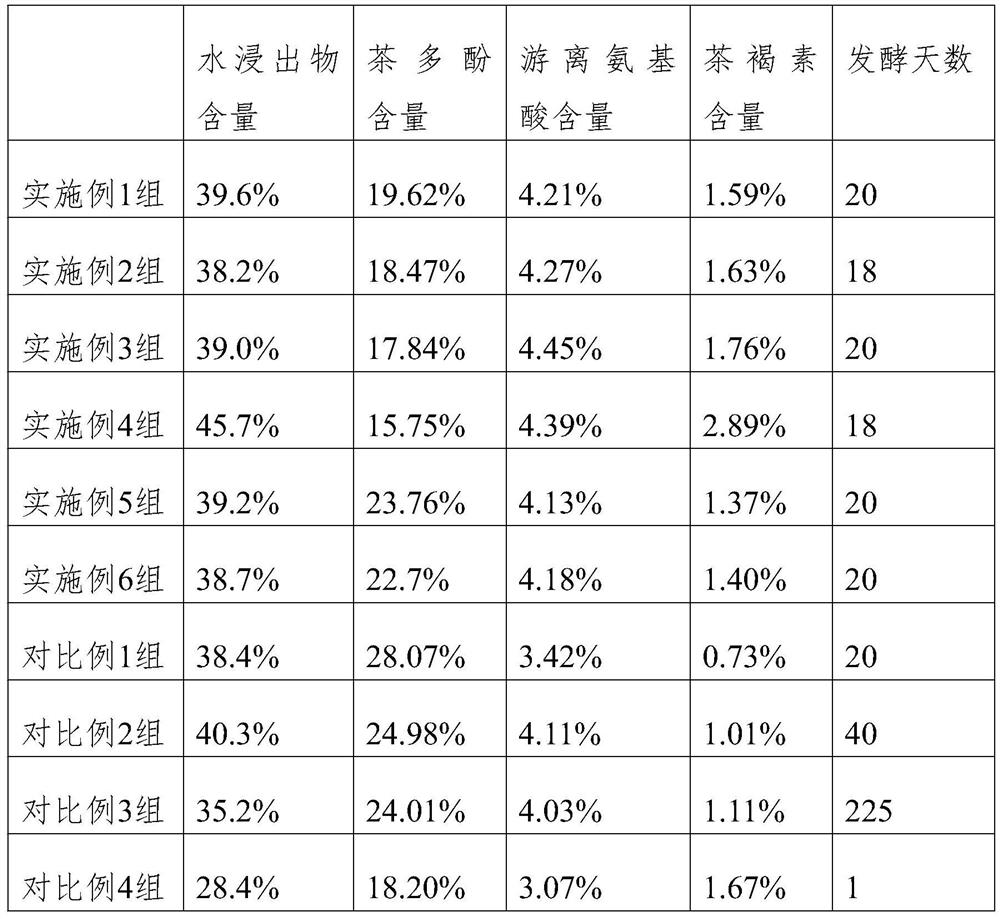

Examples

Embodiment 1

[0019] (1) Take by weighing 100kg of sun-dried green hair tea;

[0020] (2) Weigh 50g of compound enzyme with an activity of 100,000 U / g and dissolve it in 10L of deionized water, spray the prepared aqueous solution on the sun-dried green hair tea, stir evenly, humidify the tea leaves, and take a little deionized water in addition, Adjust the water content of the tea leaves to 26%, and stir evenly;

[0021] (3) Divide the humidified tea leaves into 5 parts on average, each weighing 25 kg, and put them in bamboo baskets without compacting them;

[0022] (4) Put the tea leaves in bamboo baskets into the tea fermenter for fermentation. The conditions of the fermenter are set at 30°C and 90% humidity. Turn the pile every 3 days. During the fermentation process, ventilate once every 4 hours , and control the water content of the tea leaves at 20-26%, and ferment for 20 days to obtain.

[0023] The compound enzyme is compounded by cellulase and papain according to the activity (U)...

Embodiment 2

[0025] (1) Take by weighing 90kg of sun-dried green hair tea;

[0026] (2) Weigh 27g of compound enzyme with an activity of 250,000 U / g and dissolve it in 9L of deionized water, spray the prepared aqueous solution on the sun-dried green hair tea, stir evenly, humidify the tea leaves, and take a little deionized water in addition, Adjust the water content of the tea leaves to 26%, and stir evenly;

[0027] (3) Divide the humidified tea leaves on average into 3 parts, each weighing 30 kg, and put them in bamboo baskets without compacting them;

[0028] (4) Put the tea leaves in bamboo baskets into the tea fermentation machine for fermentation. The conditions of the fermentation machine are set at a temperature of 35°C and a humidity of 95%. Turn the pile every 4 days. During the fermentation process, ventilate once every 4 hours , and control the water content of the tea leaves at 20-26%, and ferment for 18 days to obtain.

[0029] The compound enzyme is compounded by cellulas...

Embodiment 3

[0031] (1) Take by weighing 100kg of sun-dried green hair tea;

[0032] (2) Weigh 50g of compound enzyme with an activity of 100,000 U / g and dissolve it in 10L of deionized water, spray the prepared aqueous solution on the sun-dried green hair tea, stir evenly, humidify the tea leaves, and take a little deionized water in addition, Adjust the water content of the tea leaves to 26%, and stir evenly;

[0033] (3) Divide the humidified tea leaves into 5 parts on average, each weighing 25 kg, and put them in bamboo baskets without compacting them;

[0034] (4) Put the tea leaves in bamboo baskets into the tea fermenter for fermentation. The conditions of the fermenter are set at 30°C and 90% humidity. Turn the pile every 3 days. During the fermentation process, ventilate once every 4 hours , and 5 days before the start of fermentation, the water content of the tea leaves should be controlled at 25% to 26%. On the 6th to 15th day of fermentation, the water content of the tea leave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com