Method for continuously and quickly preparing high-nickel nickel-cobalt-manganese ternary material precursor

A ternary material and precursor technology, used in electrical components, battery electrodes, circuits, etc., can solve the problems of long preparation cycle, uncontrollable reaction process, and difficult to control product particle size, and achieve good particle size uniformity and shortening. Production cycle, effect with industrial applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Steps:

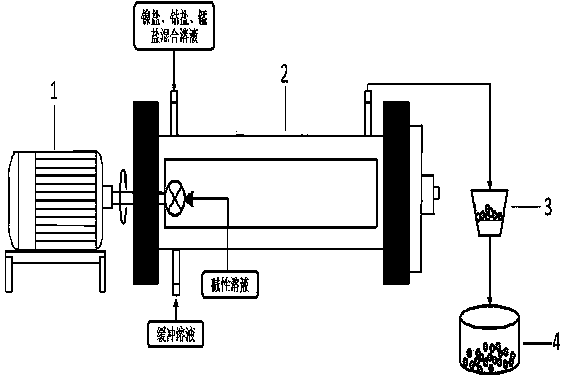

[0050] (1) A mixed solution of nickel sulfate, manganese sulfate and cobalt sulfate (the total concentration of the mixed solution is 3mol / L, of which Ni 2+ , Mn 2 + and Co 2+ The concentration ratio is 9:0.5:0.5) using a peristaltic pump to blow into the reaction tank of the Taylor vortex crystallizer at a flow rate of 10mL / min. The process flow is as follows figure 1 As shown; at the same time, the NaOH solution with a concentration of 6mol / L and the ammonia solution with a concentration of 1mol / L are fed into the reaction tank in parallel at the flow rate of 10mL / min and 1mL / min respectively through two peristaltic pumps, and the vortex crystallizer is used to The temperature control system, adjust the reaction tank reaction temperature to 50 o C. The rotation speed of the inner column of the crystallizer driven by the motor is set to 1000rpm, and the pH of the entire reaction system is controlled to be 12. The feed liquid in the reaction tank in the T...

Embodiment 2

[0053] Steps:

[0054] (1) A mixed solution of nickel sulfate, manganese sulfate and cobalt sulfate (the total concentration of the mixed solution is 3mol / L, of which Ni 2+ , Mn 2 + and Co 2+ The concentration ratio is 8:1:1) using a peristaltic pump to blow into the reaction tank of the Taylor vortex crystallizer at a flow rate of 10mL / min. The process flow is as follows figure 1 As shown; at the same time, the NaOH solution with a concentration of 6mol / L and the ammonia solution with a concentration of 1mol / L are fed into the reaction tank in parallel at the flow rate of 10mL / min and 1mL / min respectively through two peristaltic pumps, and the vortex crystallizer is used to The temperature control system, adjust the reaction tank reaction temperature to 50 o C. The rotation speed of the inner column of the crystallizer driven by the motor is set to 1000rpm, and the pH of the entire reaction system is controlled to be 12. The feed liquid in the reaction tank in the Taylo...

Embodiment 3

[0057] Steps:

[0058] (1) A mixed solution of nickel sulfate, manganese sulfate and cobalt sulfate (the total concentration of the mixed solution is 3mol / L, of which Ni 2+ , Mn 2 + and Co 2+ The concentration ratio is 7:1.5:1.5) using a peristaltic pump to blow into the reaction tank of the Taylor vortex crystallizer at a flow rate of 10mL / min. The process flow is as follows figure 1 As shown; at the same time, the NaOH solution with a concentration of 6mol / L and the ammonia solution with a concentration of 1mol / L are fed into the reaction tank in parallel at the flow rate of 10mL / min and 1mL / min respectively through two peristaltic pumps, and the vortex crystallizer is used to The temperature control system, adjust the reaction tank reaction temperature to 50 o C. The rotation speed of the inner column of the crystallizer driven by the motor is set to 1000 rpm, and the pH of the entire reaction system is controlled to be 12. The feed liquid in the reaction tank in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com