Novel drill pipe shackle assembling and centering device

A centering device and drill pipe technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of high risk, high labor intensity, high risk factor, etc., achieve safe operation, eliminate manual operation, and facilitate disassembly and transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

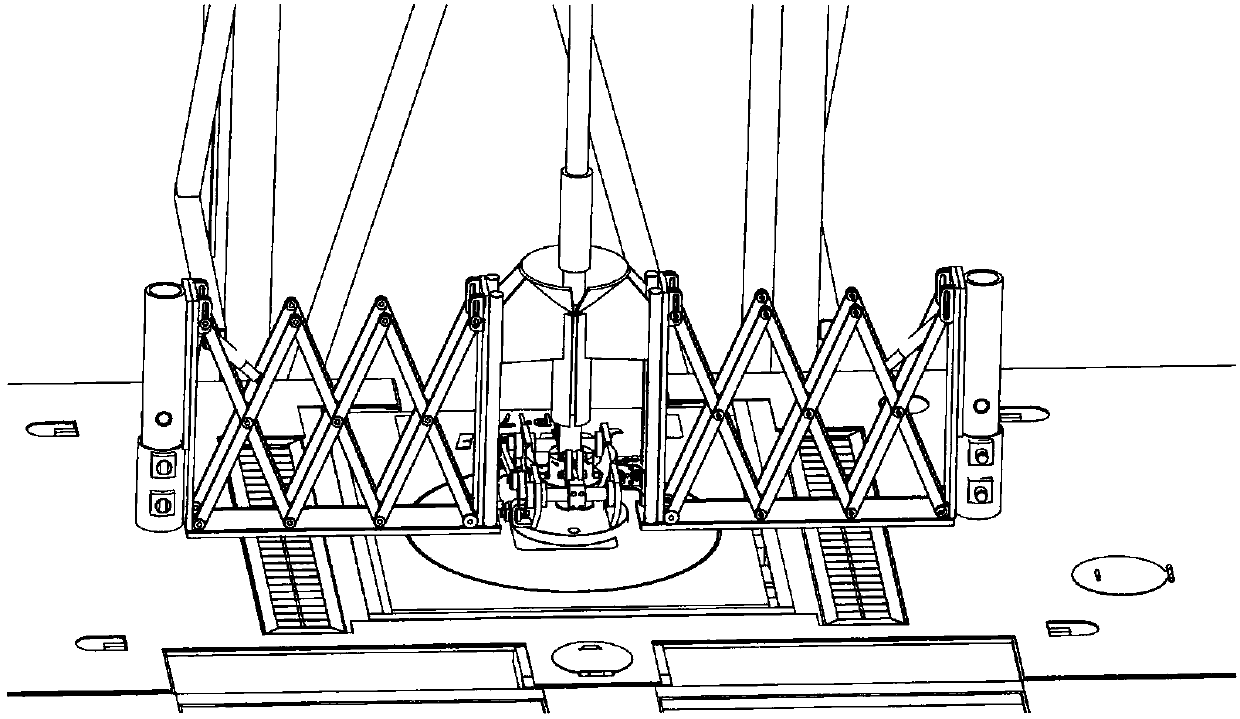

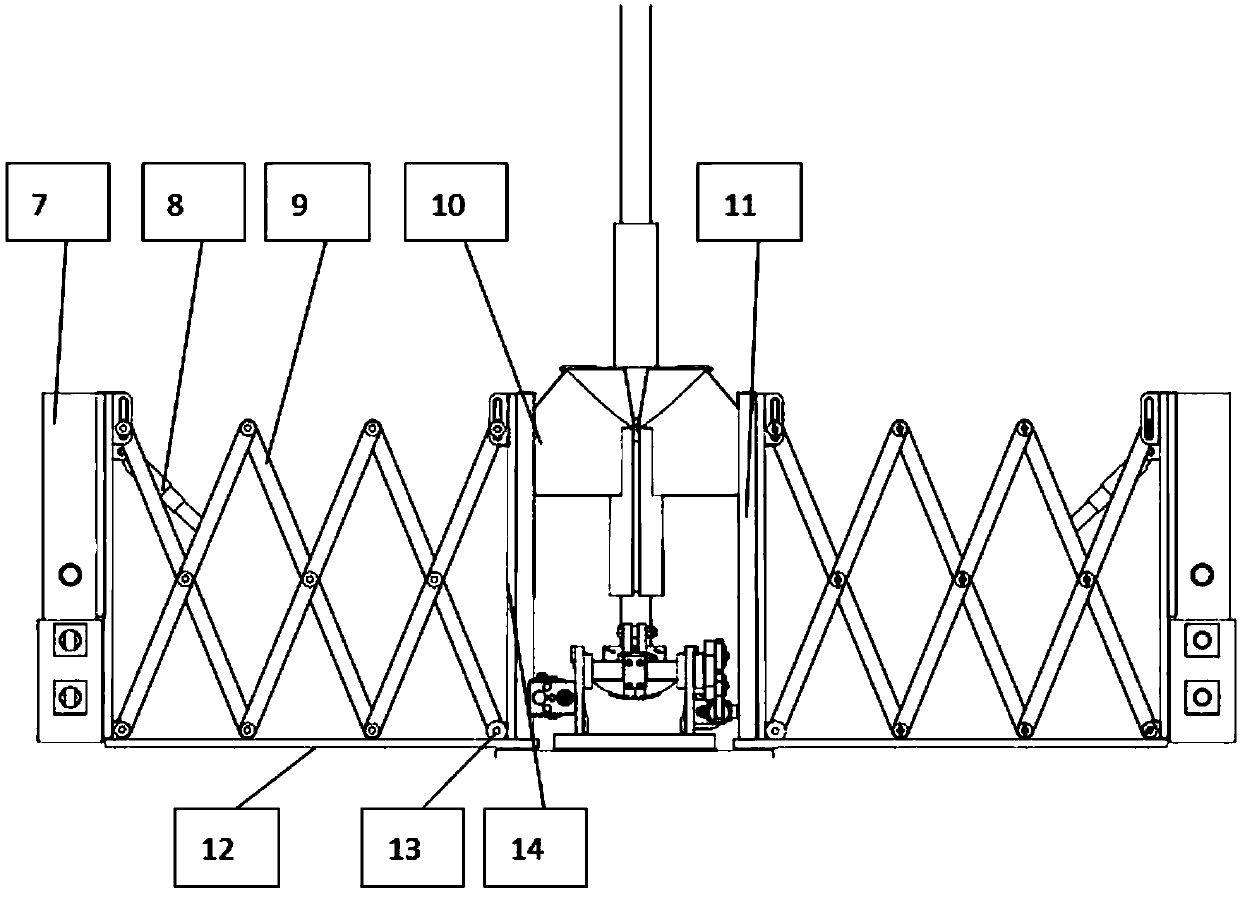

[0017] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0018] A new type of drill pipe make-up centering device mainly consists of: 7-connecting pile, 8-hydraulic cylinder, 9-connecting rod, 10-centering groove, 11-spring, 12-slide, 13-roller, 14- Centering groove vertical guide rail, 15-centering groove bell mouth, 16-centering groove clamping block.

[0019] A new type of centering device for drill pipe make-up, including two sets of left and right symmetrical structures. When the drill pipe is centered and make-up, the hydraulic cylinders 8 of the two centering devices are stretched out, pushing the connecting rod 9 to move, and driving the centering groove 10 to clamp Holding the fixed drill pipe 5, the drill pipe 6 to be connected is guided through the bell mouth 15 of the centering groove to align the centers of the two drill pipes, then the hydraulic cylinder 8 retracts, drives the connecting rod 9 to retract, and the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com