Form fitting method of single laminating plate and inner wall

A technology of laminated panels and interior walls, applied in the direction of walls, floors, formwork/formwork/working frames, etc., to achieve the effect of preventing concrete grout leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

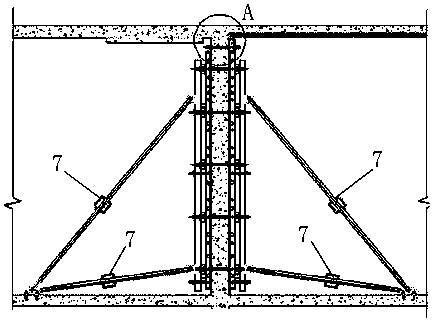

[0020] Such as Figure 1-2 Shown: a kind of one-sided laminated plate and interior wall formwork matching method, it comprises the following steps:

[0021] Step 1: After the internal wall reinforcement binding and water and electricity pre-embedding are completed, the internal wall formwork 1 is installed after passing the acceptance;

[0022] Step 2: Set up supporting scaffolding on the outside of the inner wall formwork;

[0023] Step 3: Install a 5mm-thick adjusting rubber strip 2 on the top of the interior wall formwork in the single-sided laminated slab area. The adjusting rubber strip is O-shaped and made of rubber material to prevent grout leakage during concrete pouring ;

[0024] Step 4: hoisting the laminated board 3;

[0025] Step 5: Binding steel bars on the surface layer of the laminated board;

[0026] Step 6: Pre-embed the diagonal support feet 7 of the aluminum alloy wall formwork, check the distance between the diagonal braces and the length of the bolt l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com