Automatic stamping device

An automatic and motor-driven technology, applied in printing, stamping and other directions, can solve the problems of different sizes of drawings and inability to meet the needs of functions, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

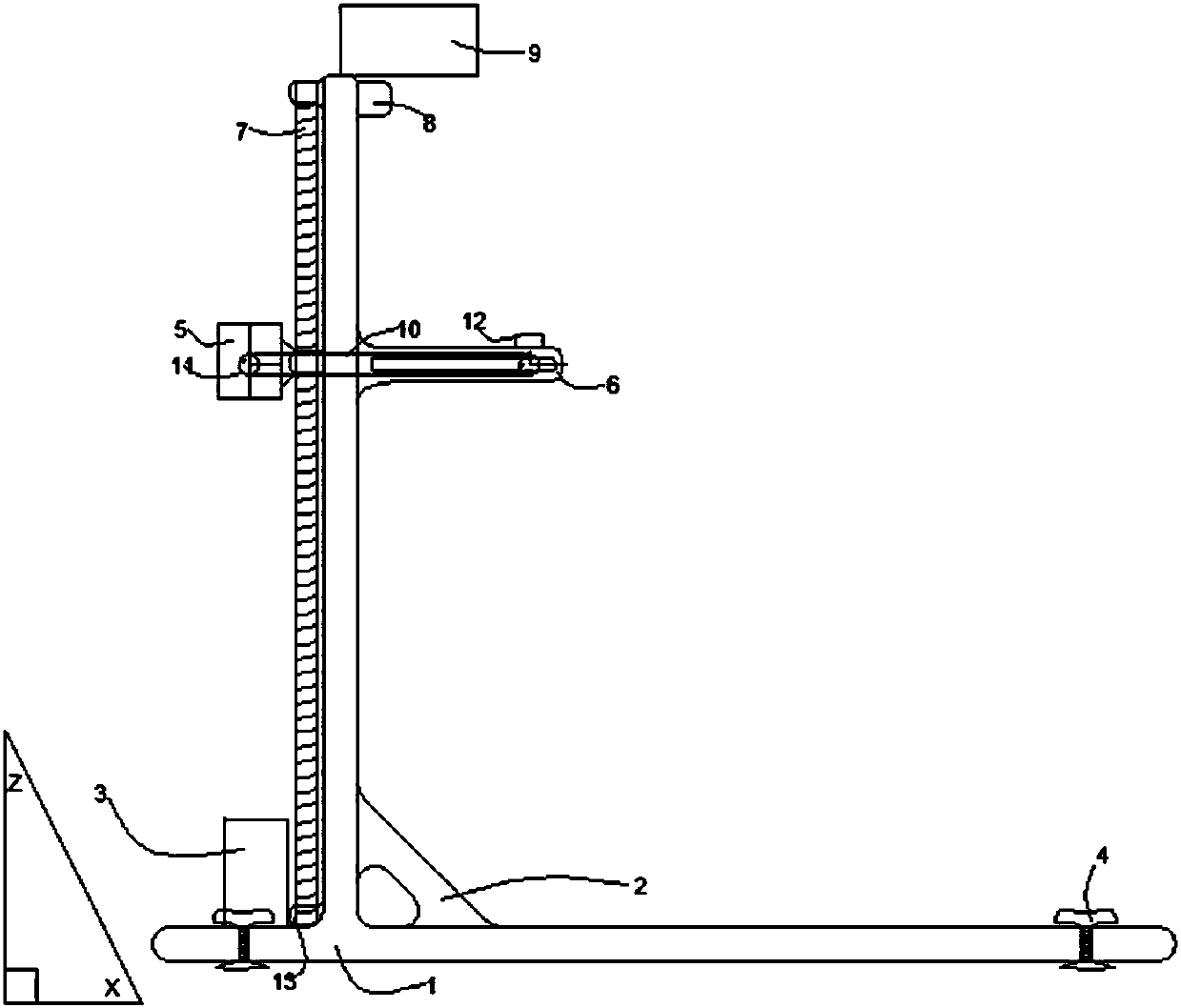

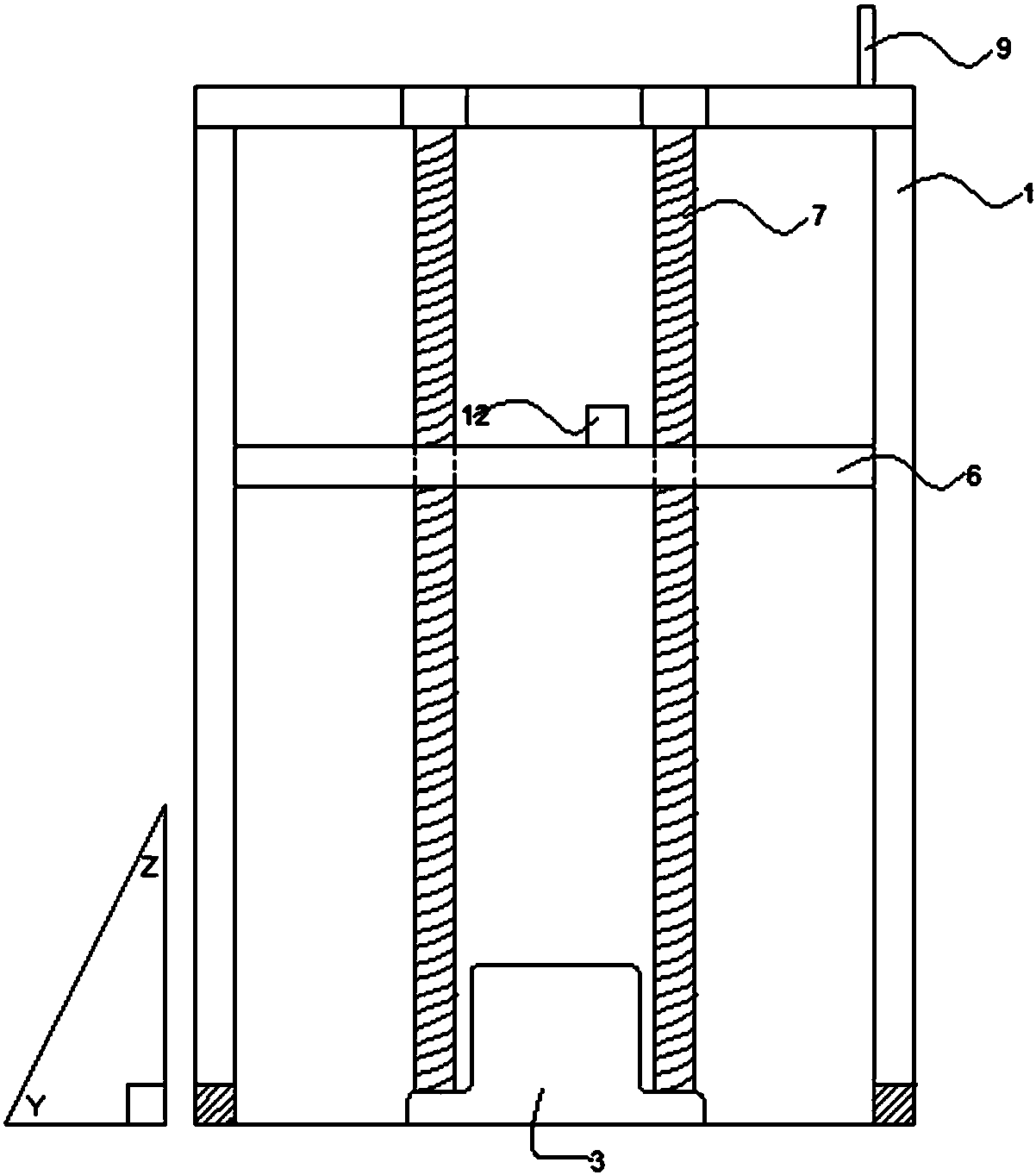

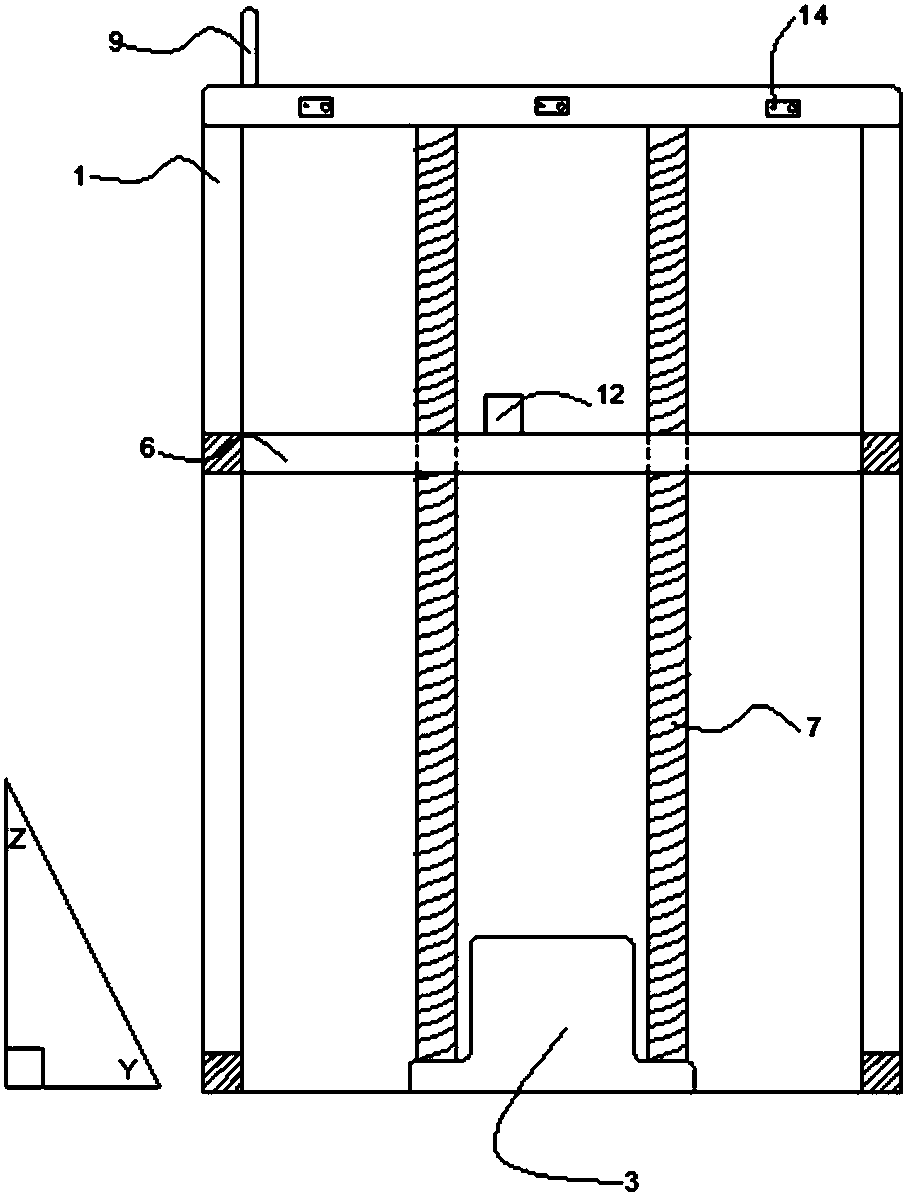

[0023] see Figure 1-7 , an automatic stamping device, comprising a main frame 1, a support plate 2 and a support 6, the main frame 1 is provided with a support 6, and the support 6 is slidingly connected with the main frame 1, and the main frame 1 is provided with T-shaped slot, the corresponding position on the support 6 contains a pulley corresponding to the T-shaped slot of the main frame 1, so that the support 6 can reduce the damping coefficient when sliding up and down to reduce friction; the main frame 1 is provided with a support plate 2 , the support plate 2 can ensure that the vertical beams of the main frame 1 are perpendicular to each other, and play a fixed support role; the upper side of the main frame 1 is fixedly equipped with a liquid crystal touch screen 9, and four balance knobs 4 are placed on the four corners of the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com