Energy storage device for air compressor waste heat reuse

A technology of energy storage device and air compressor, which is applied in the direction of mechanical equipment, machine/engine, liquid variable capacity machinery, etc. It can solve the problems of thermal energy not being effectively used, not meeting energy saving requirements, waste, etc., and achieve temperature balance , Improve the utilization rate and avoid the effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

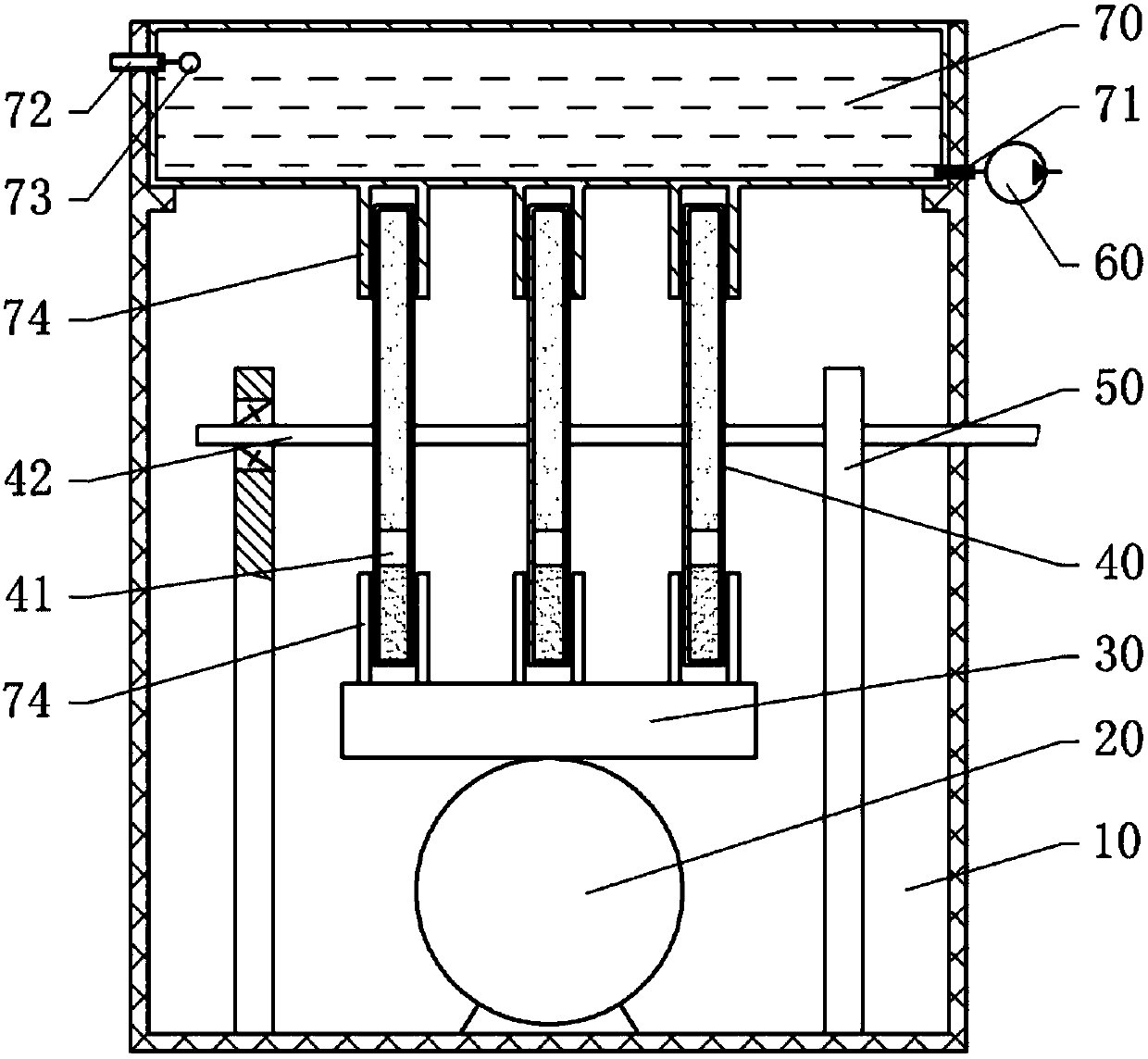

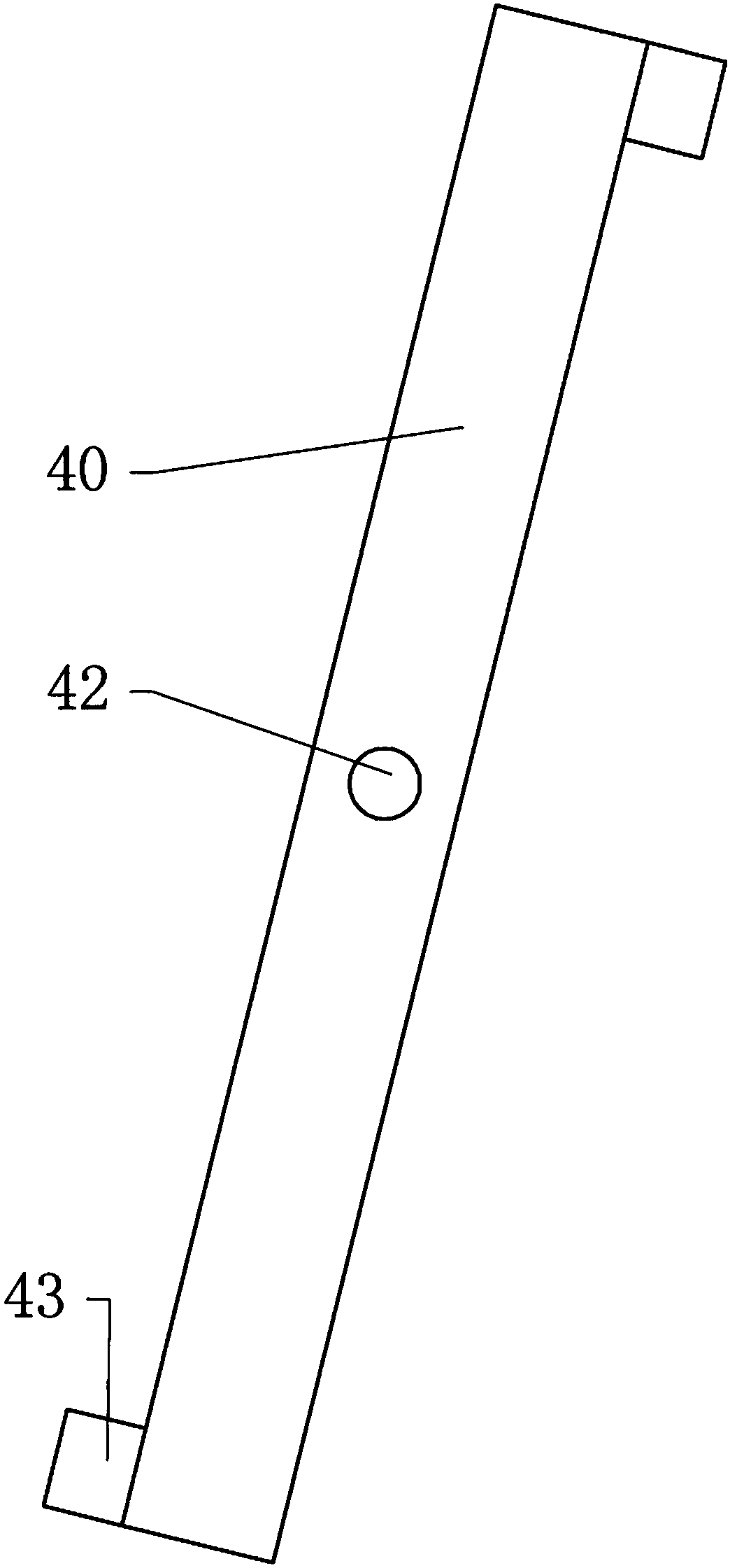

[0027] Such as figure 1 , figure 2 As shown, the energy storage device for reuse of waste heat from an air compressor includes an air compressor room 10 , an air compressor 20 is located in the air compressor room 10 , and a cooler 30 is connected to the air compressor 20 . The top of the air compressor room 10 is provided with a heat absorbing tank 70 and a water pump 60 , and the air compressor room 10 is provided with a heat energy conversion mechanism. The thermal energy conversion mechanism includes a bracket 50 fixed in the air compressor room 10 , a cylinder 40 mounted on the bracket 50 , and a piston 41 inside the cylinder 40 that can slide along the length of the cylinder 40 . The middle part of the cylinder body 40 is fixed with a rotating shaft 42, and the rotating shaft 42 is connected with the support 50 through a one-way bearing so that the cylinder body 40 can only rotate in one direction; The force on the end changes, so that the cylinder 40 will constantly ...

Embodiment 2

[0035] The difference between Embodiment 2 and Embodiment 1 is that in Embodiment 2, the impeller of the water pump is not connected to the rotating shaft of the cylinder body, but the water pump is driven through the electric connection between the generator and the water pump. Faster, the greater the current generated by the engine, the greater the speed of the water pump.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com