Surrounding rock control technology for large-deformation stoping roadway after anchor removing, roadway enlarging and shed substituting

A technology of mining roadway and control technology, which is applied in mining equipment, earthwork drilling, installation of bolts, etc., can solve the problems of high construction cost of a single process, difficult to play an effective support bearing body, unable to fully play the support strength and other problems, To achieve the effect of standardization and low cost of process flow, promoting the stability of surrounding rock, and low supporting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

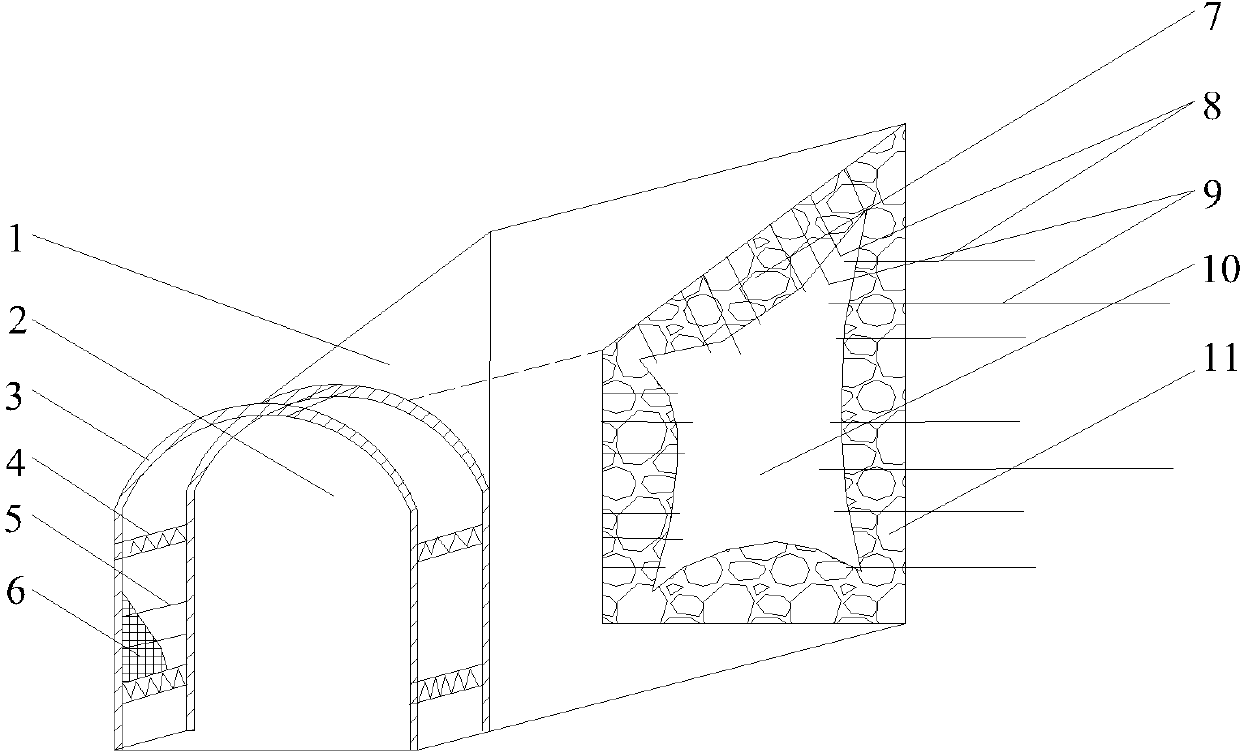

[0022] Such as figure 1 As shown, the present invention provides a large-deformation recovery roadway anchor removal expansion roadway replacement shed surrounding rock control technology, the technology mainly includes the following steps:

[0023] Step 1: Investigate the brokenness of the surrounding rock of the large-deformation mining roadway 10 and the tensile fracture of the anchor rod 8 and the anchor cable 9, and design the roadway expansion method of the large-deformation mining roadway 10 by lifting the roof 7 to expand the roadway, and the section shape of the replacement shed roadway 2 is straight The wall is arched, and the size of the cross-section of the tunnel 2 of the shed meets the service function and use requirements;

[0024] Step 2: According to the design requirements of the large-deformation recovery roadway 10 repairing sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com