Switchable double gear wheel for a double clutch transmission, and double clutch transmission

A dual-clutch transmission and dual-gear technology, which is applied to vehicle gearboxes, gear transmissions, belts/chains/gears, etc., can solve the problems of high cost, reduce speed difference, reduce support costs, and simplify axial support. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

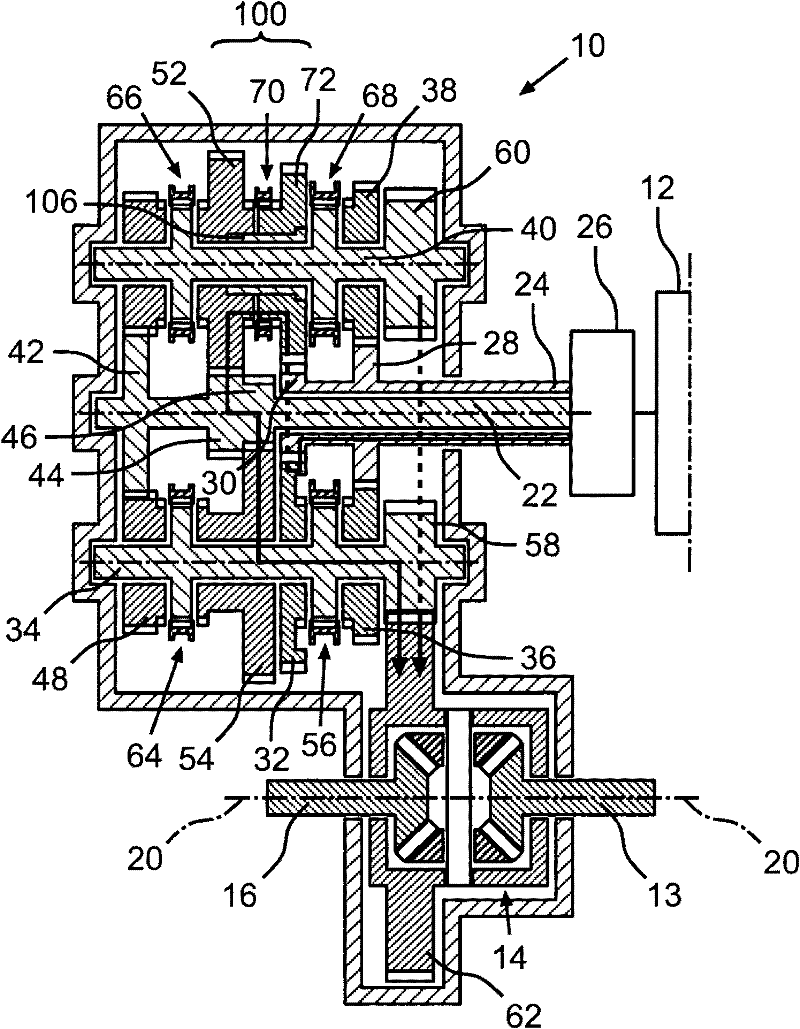

[0022] figure 1 A front-transverse (frontquer-Bauweise) dual-clutch transmission 10 is shown in FIG. In the plane of the drawing, the internal combustion drive engine 12 is located on the right. The differential 14 is coupled with wheel drive axle shafts 16 , 18 for output to the front axle 20 . The transmission shaft shown here is only shown simplified in the plane of the drawing. In a practical implementation, the four main geometric axes are offset from one another in a spatially parallel manner.

[0023] The dual clutch transmission 10 has input-side transmission input shafts, one of which is designed as a radially inner shaft 22 and the other as an outer hollow shaft 24 enclosing an axially right-hand section of this inner shaft 22 .

[0024] Two main clutches (not shown in more detail) of a dual clutch 26 are arranged on the right-hand end of the two transmission input shafts 22 , 24 , that is to say close to the drive motor. Each of the two main clutches is friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com