Cold-resisting (40 DEG C below zero) and high-flame retardant (OI is greater than or equal to 38) PVC (Polyvinyl Chloride) cable material and preparation method thereof

A high flame retardant, cable material technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problem that cold resistance and flame retardancy cannot be taken into account at the same time, and achieve good processing performance and stable glue output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

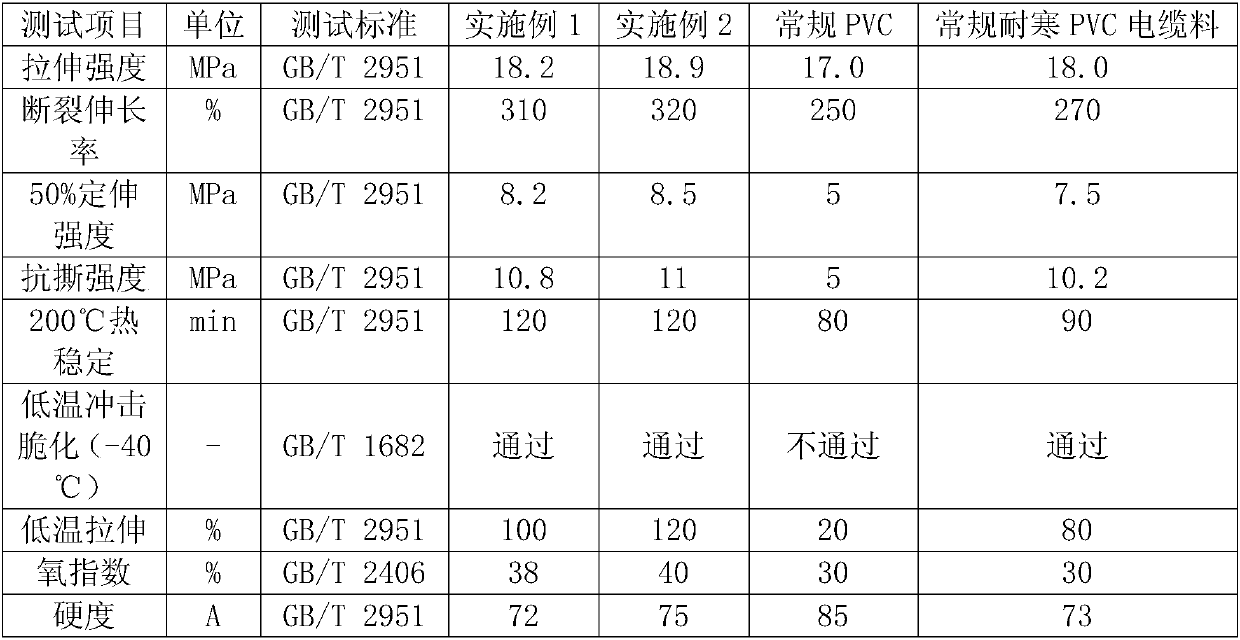

Examples

Embodiment Construction

[0050] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

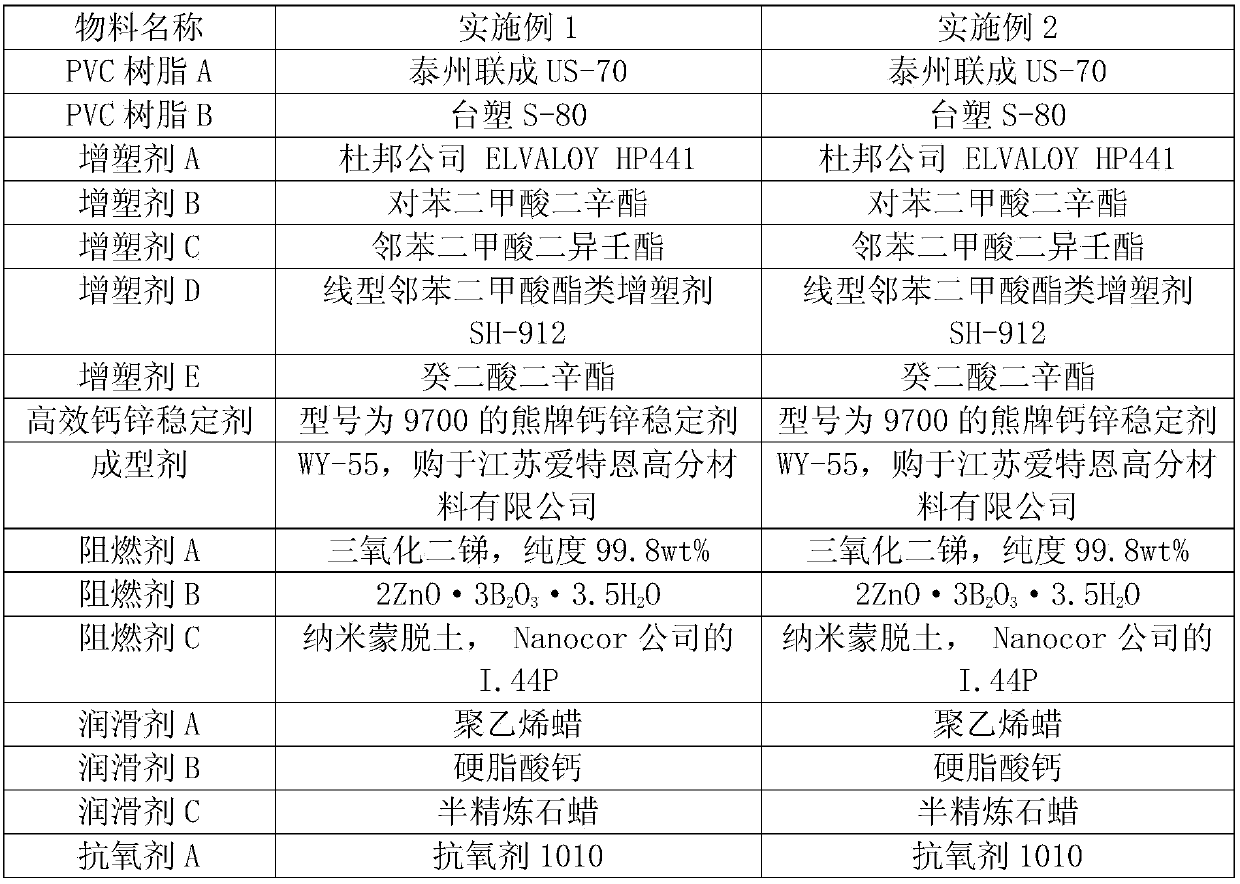

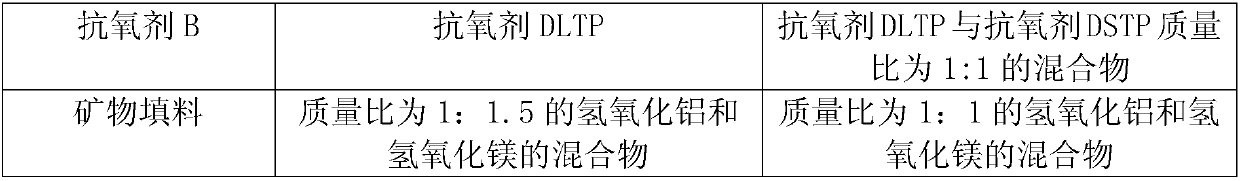

[0051] The table of raw material components used in each embodiment of table 1

[0052] Material name

Example 1

Example 2

PVC resin A

50

50

PVC resin B

50

50

10

15

16

18

16

18

Plasticizer D

20

25

Plasticizer E

5

8

Efficient calcium zinc stabilizer

8

6

Forming agent

2

3

Flame retardant A

5

10

Flame retardant B

5

7

Flame retardant C

5

6

0.5

0.8

0.5

0.8

0.8

0.5

1

1

1

2

mineral filler

50

60 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com