Heat dissipation method for transformer station

A heat dissipation method and substation technology, applied in the cooling/ventilation of substation/switchgear, non-variable pumps, components of pumping devices for elastic fluids, etc., can solve the problems of low heat dissipation efficiency and improve heat dissipation Efficiency, large heat dissipation area or heat exchange area, and the effect of increasing the working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

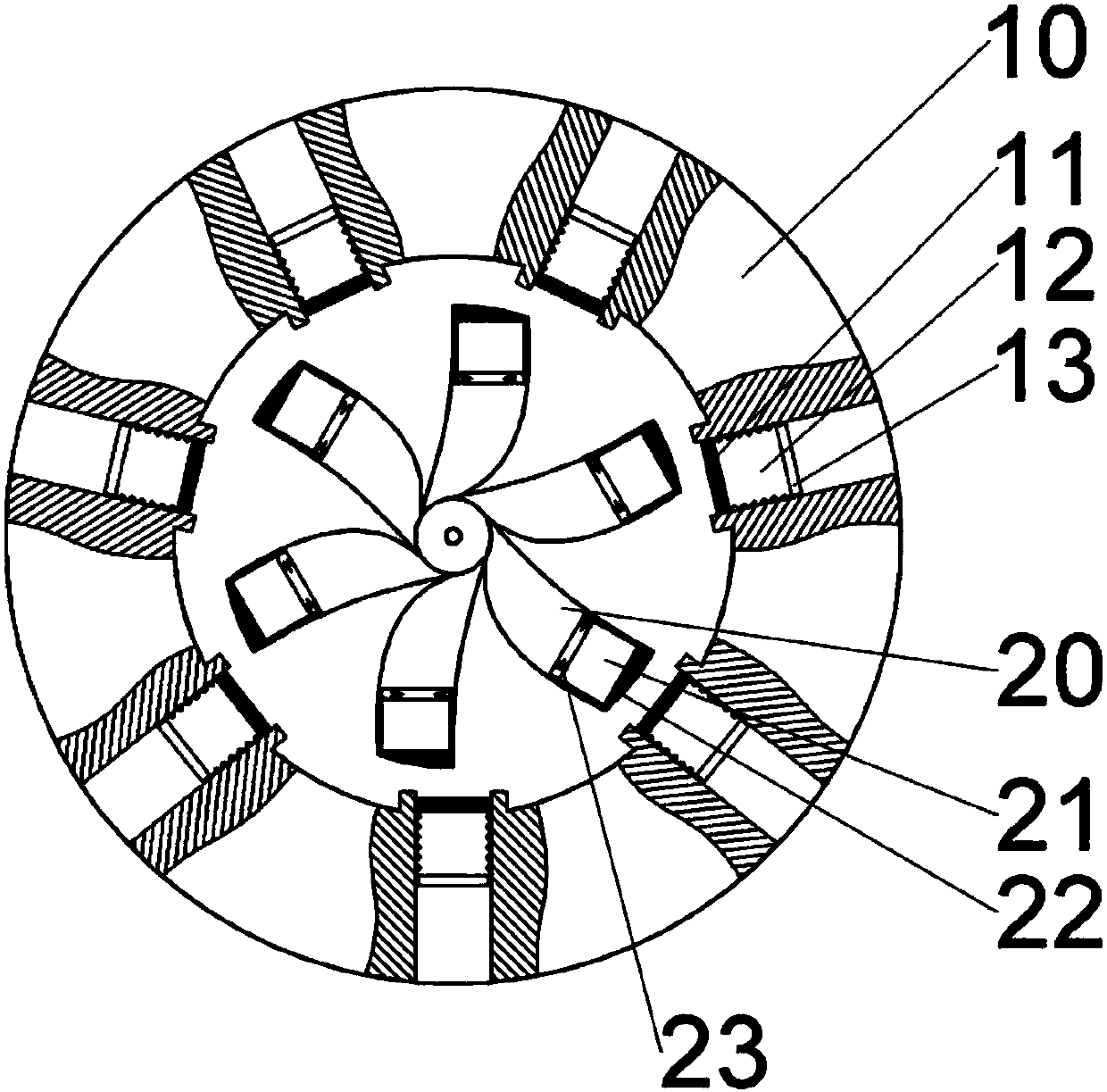

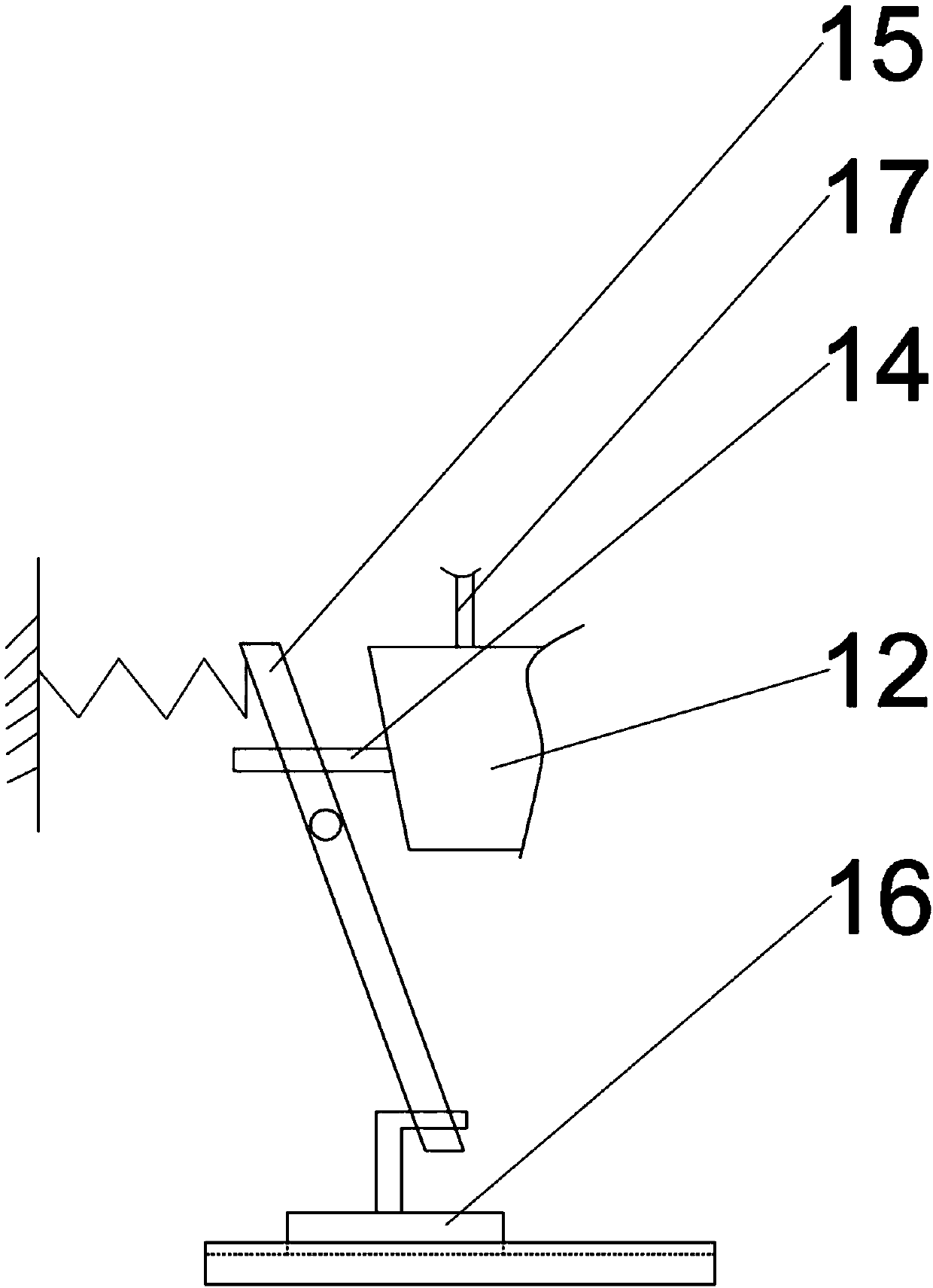

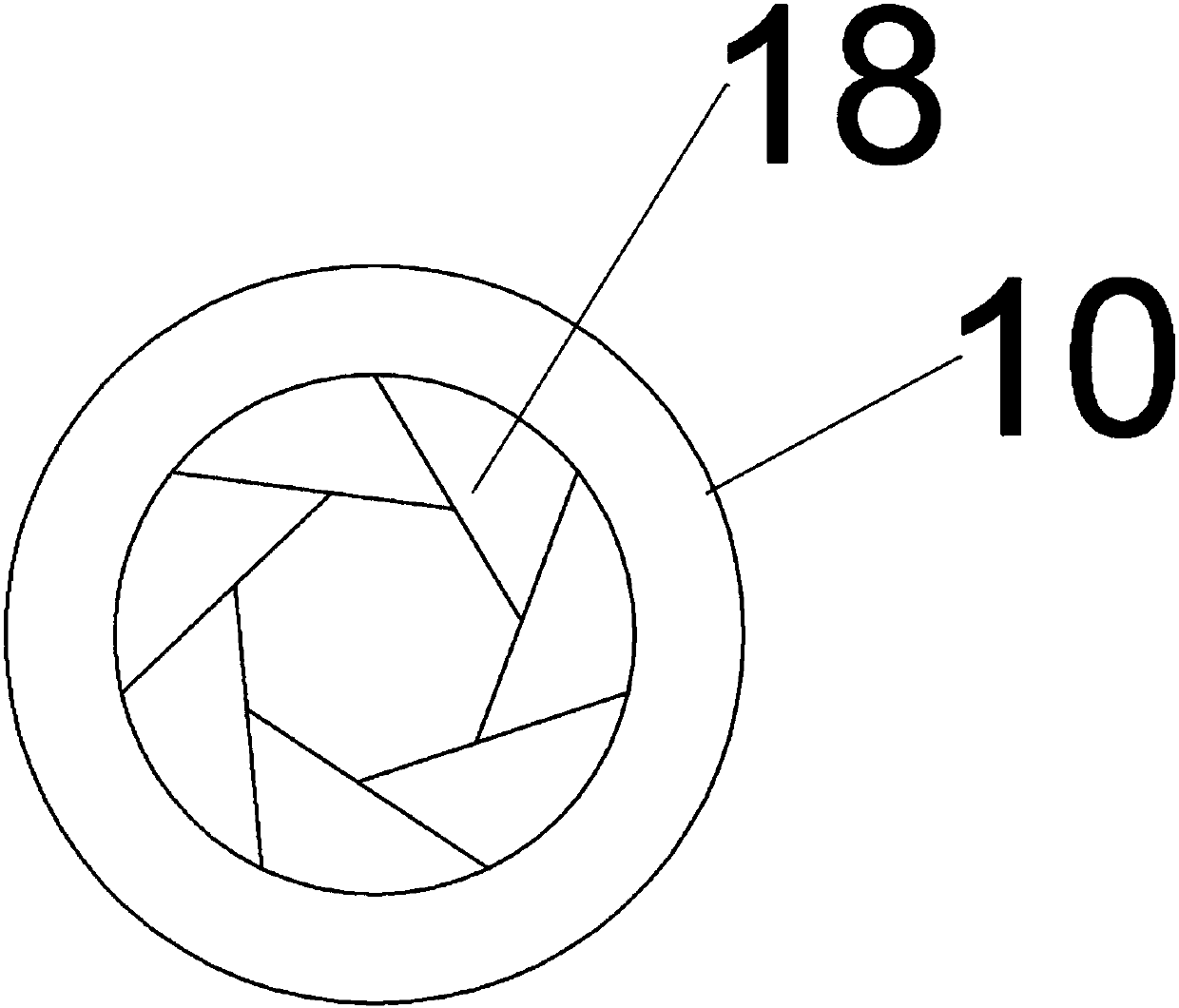

[0026] Basic as attached figure 1 As shown, the heat dissipation device of the substation includes a frame, and also includes cooling holes arranged on the frame. A cooling fan and a dust-proof sheet for adjusting the working area of the cooling hole are sequentially arranged in the cooling hole along the axial direction. The cooling fan includes Rotate the rotating shaft arranged on the frame, the blade fixedly connected with the rotating shaft, slide the sliding block arranged on the outer end of the blade, a tension spring is arranged between the inner end of the sliding block and the blade, and the first magnetic body is fixed on the outer end of the sliding block; heat dissipation A second magnetic body is slidably arranged on the outer wall of the hole, and a top plate is also fixed on the second magnetic body, and an air bag is also fixed between the top plate and the second magnetic body. The second magnetic body and the first magnetic body are mutually repulsive. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com