Micro beam tube bow type drop optical cable

A technology for introducing optical cables and micro-bundle tubes, applied in the direction of light guides, optics, optical components, etc., to achieve the effects of easy peeling, simple access, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

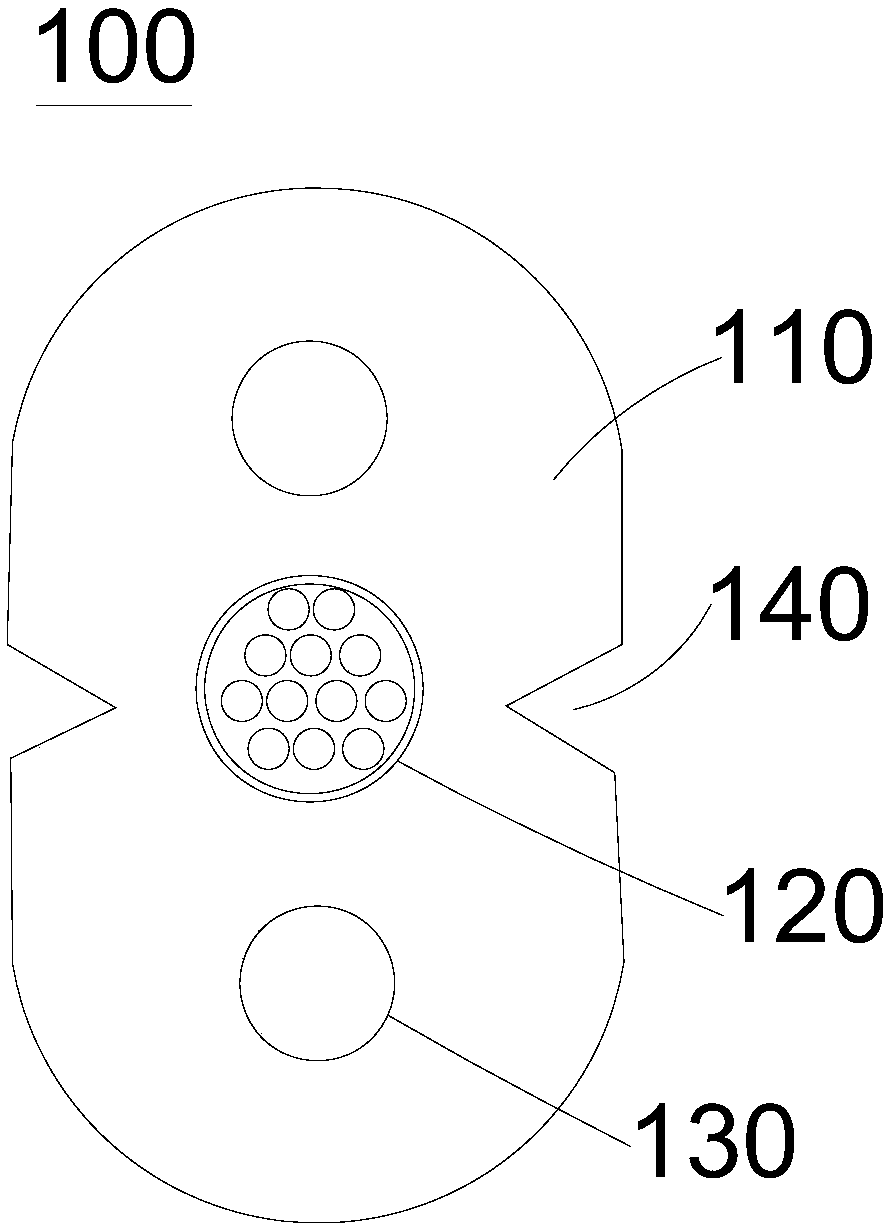

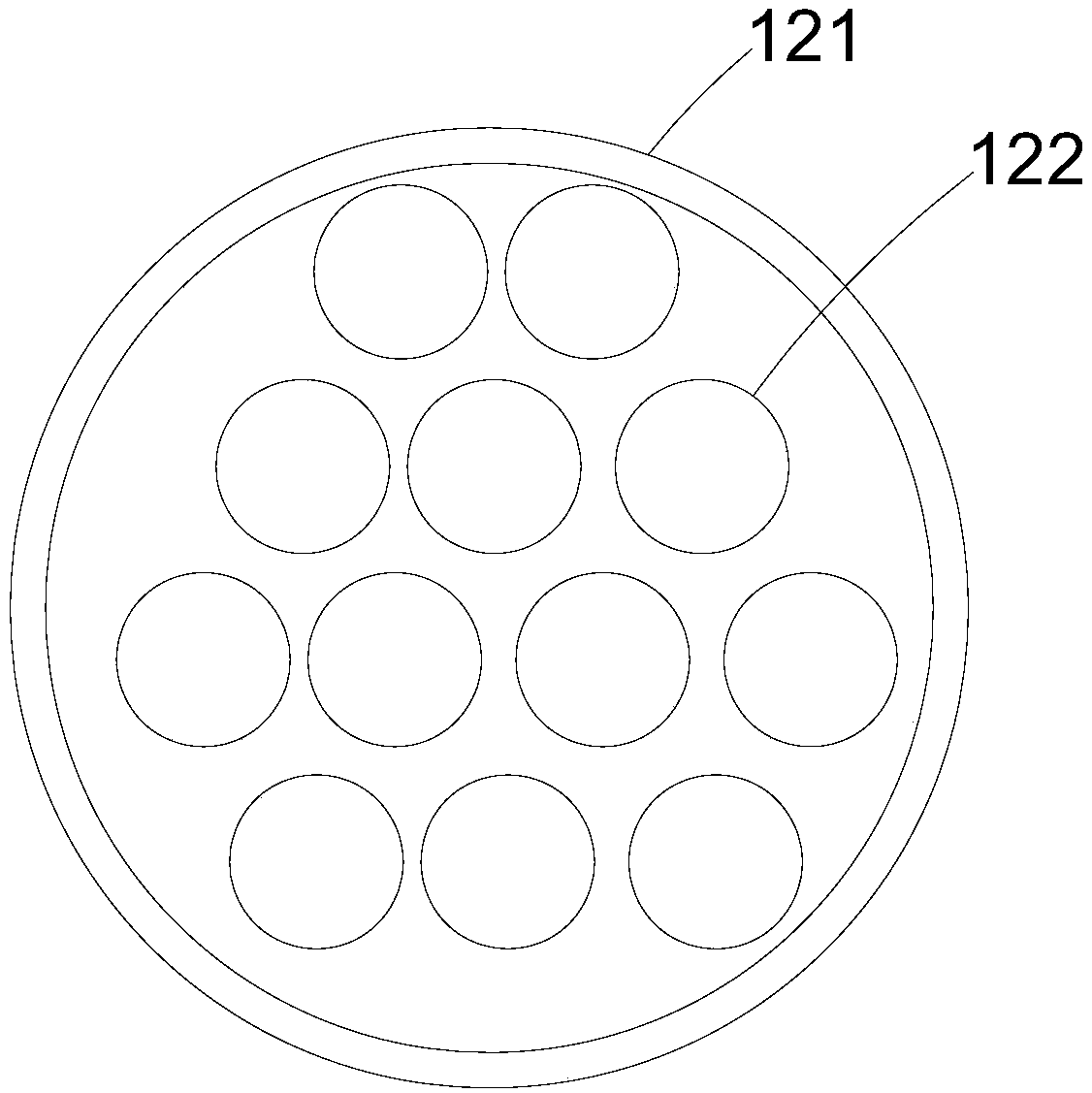

[0029] This embodiment provides a micro-bundle tube 121 butterfly-shaped drop-in cable, please refer to figure 1 , this micro-bundle tube 121 butterfly-shaped lead-in cable includes a cable body 100, and the cable body 100 includes a sheath 110, an optical communication unit 120, and a strengthening member 130; the sheath 110 is wrapped on the outside of the optical communication unit 120 and the strengthening member 130; please refer to image 3 , the optical communication unit 120 includes a micro-bundle tube 121 and a plurality of optical fibers 122, there are four optical fibers 122, the optical fibers 122 are placed inside the micro-bundle tube 121, and the micro-bundle tube 121 is made of polyolefin material.

[0030] The optical cable body 100 is flat as a whole. The thickness of the sheath 110 ( figure 1 Middle transverse dimension) is 2mm, the width of sheath 110 ( figure 1 The middle longitudinal dimension) is 3 mm; the distance between the stiffener 130 and the e...

Embodiment 2

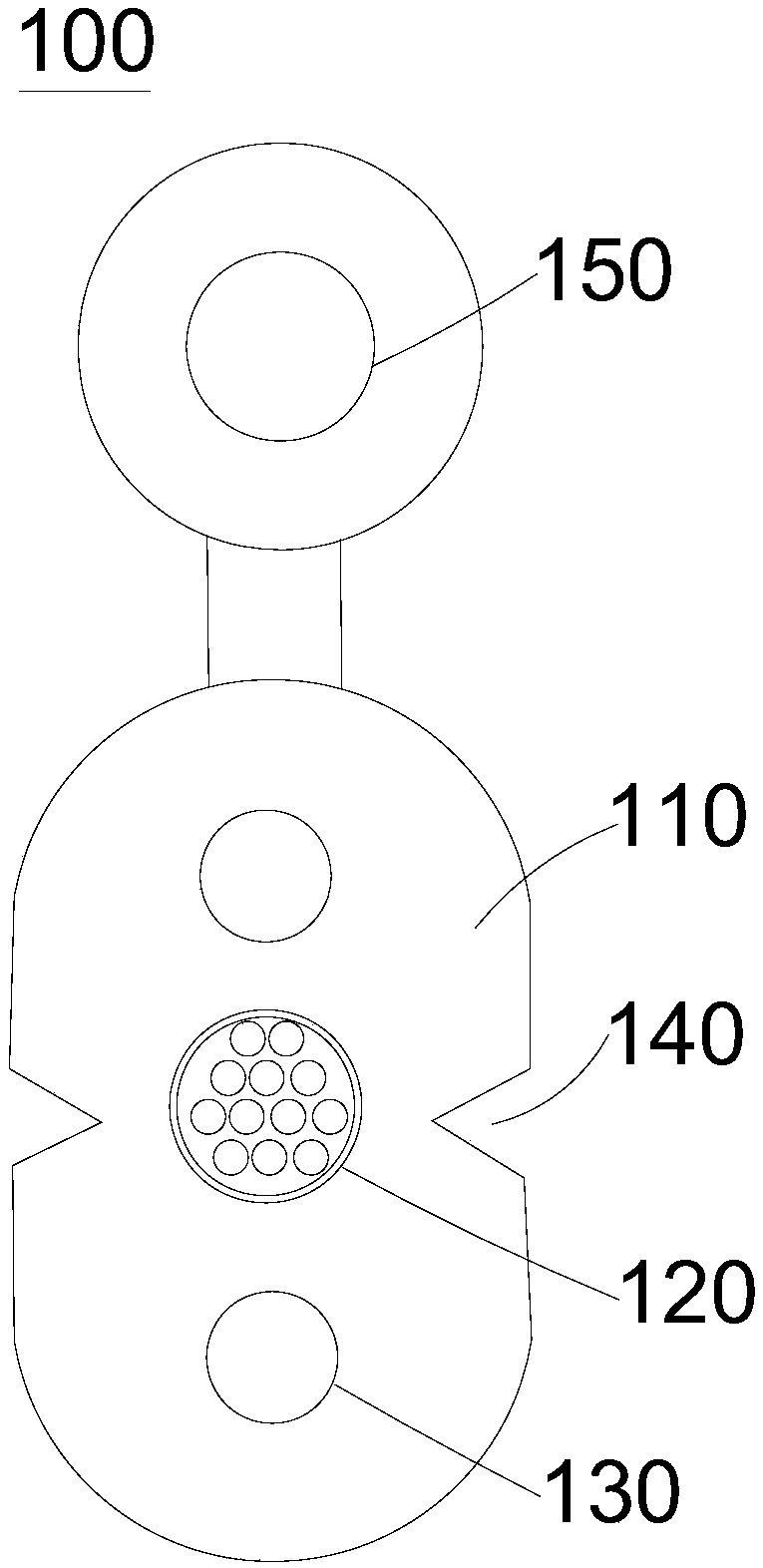

[0038] This embodiment provides a micro-bundle tube 121 butterfly-shaped drop-in cable, please refer to figure 2 , this micro-bundle tube 121 butterfly-shaped lead-in cable includes an optical cable body 100, and the optical cable body 100 includes a sheath 110, an optical communication unit 120, and a strengthening member 130; the sheath 110 is wrapped on the outside of the optical communication unit 120 and the strengthening member 130; The communication unit 120 includes a micro-bundle tube 121 and a plurality of optical fibers 122. There are 10 optical fibers 122. The optical fibers 122 are placed inside the micro-bundle tube 121. The micro-bundle tube 121 is made of polyolefin material.

[0039] The optical cable body 100 is flat as a whole. The thickness of the sheath 110 ( figure 2 Middle transverse dimension) is 2mm, the width of sheath 110 ( figure 2 The middle longitudinal dimension) is 4 mm; the distance between the stiffener 130 and the edge of the sheath 110 ...

Embodiment 3

[0045] This embodiment provides a micro-bundle tube 121 butterfly-shaped drop-in cable, please refer to figure 2 , this micro-bundle tube 121 butterfly-shaped lead-in cable includes an optical cable body 100, and the optical cable body 100 includes a sheath 110, an optical communication unit 120, and a strengthening member 130; the sheath 110 is wrapped on the outside of the optical communication unit 120 and the strengthening member 130; The communication unit 120 includes a micro-bundle tube 121 and a plurality of optical fibers 122. There are 20 optical fibers 122. The optical fibers 122 are placed inside the micro-bundle tube 121. The micro-bundle tube 121 is made of polyolefin material.

[0046] The optical cable body 100 is flat as a whole. The thickness of the sheath 110 ( figure 2 Middle transverse dimension) is 2mm, the width of sheath 110 ( figure 2 The middle longitudinal dimension) is 4.8 mm; the distance between the stiffener 130 and the edge of the sheath 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com