Method for predicating head rice rate of medium-length brown rice

A kind of technology of polished rice rate and medium-length type, which is applied in the field of accurately predicting the polished rice rate of medium-long rough valleys, which can solve the problems of difficult data repetition, multi-instrument parameters in the steps of polished rice rate, etc., and achieve good repeatability and low cost , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0030] (1) Experimental sample particles: separate out brown rice, clean rice, pick out shriveled rice impurities, etc. according to the quartering method;

[0031] (2) Use a huller to hull the brown rice for regulation, and then adjust the huller according to the hulling situation;

[0032] The grain size of the brown rice for adjustment should be similar to that of the experimental sample. First, use a laboratory huller to hull the brown rice for adjustment, and then adjust the huller to a suitable state according to the hulling situation: 1) There is no brown rice or brown rice in the detached rice hulls. Brown rice; 2) Hulled brown rice has no cortex damage; 3) Hulled brown rice has no rice husk debris.

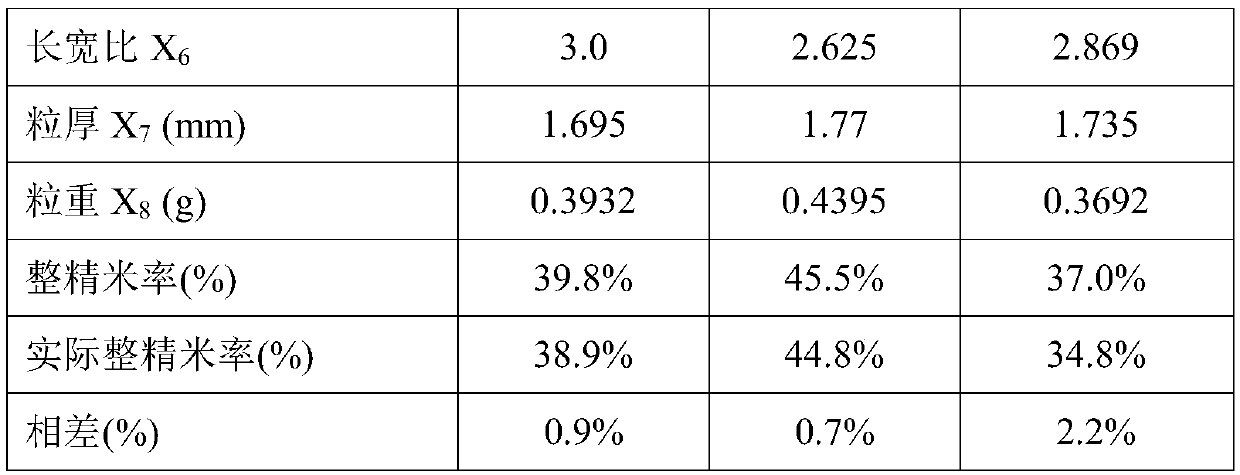

[0033] (3) Pick out 20 complete and plump brown rice grains at random, measure the appearance quality (grain length, grain width, surface area, diameter, and aspect ratio) with a rice appearance scanning measuring instrument, measure the thickness of rice grains with a ve...

Embodiment 4~6

[0043] (1) Experimental sample particles: separate the brown rice by quartering, clean the grain, and pick out shriveled grain impurities;

[0044] (2) Use a huller to hull the brown rice for adjustment, and then adjust the huller according to the hulling situation; the grain size of the brown rice for adjustment should be similar to that of the experimental sample, and first use the laboratory huller to hull the brown rice for adjustment Hull, and then adjust the huller to a suitable state according to the husking situation: 1) There is no brown rice or brown rice in the detached rice husk; 2) There is no cortex damage in the husked brown rice; 3) There is no rice husk debris in the husked brown rice.

[0045] (3) Randomly pick out 20 complete and plump brown rice grains, measure the appearance quality (grain length, grain width, surface area, diameter and aspect ratio) with a rice appearance scanning tester, measure the thickness of the rice grains with a vernier caliper, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com