Water replenishment method and water replenishment system of supercritical unit steady pressure steam blowpipe

A technology of supercritical unit and water replenishment system, which is applied in the field of supercritical unit pressure-stabilized steam blowing water replenishment method and water replenishment system, can solve problems such as time extension, waste of manpower, material resources, thermal power unit trial operation and commercial operation obstacles, etc. Water demand, improving efficiency and safety, addressing boiler water mismatch effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

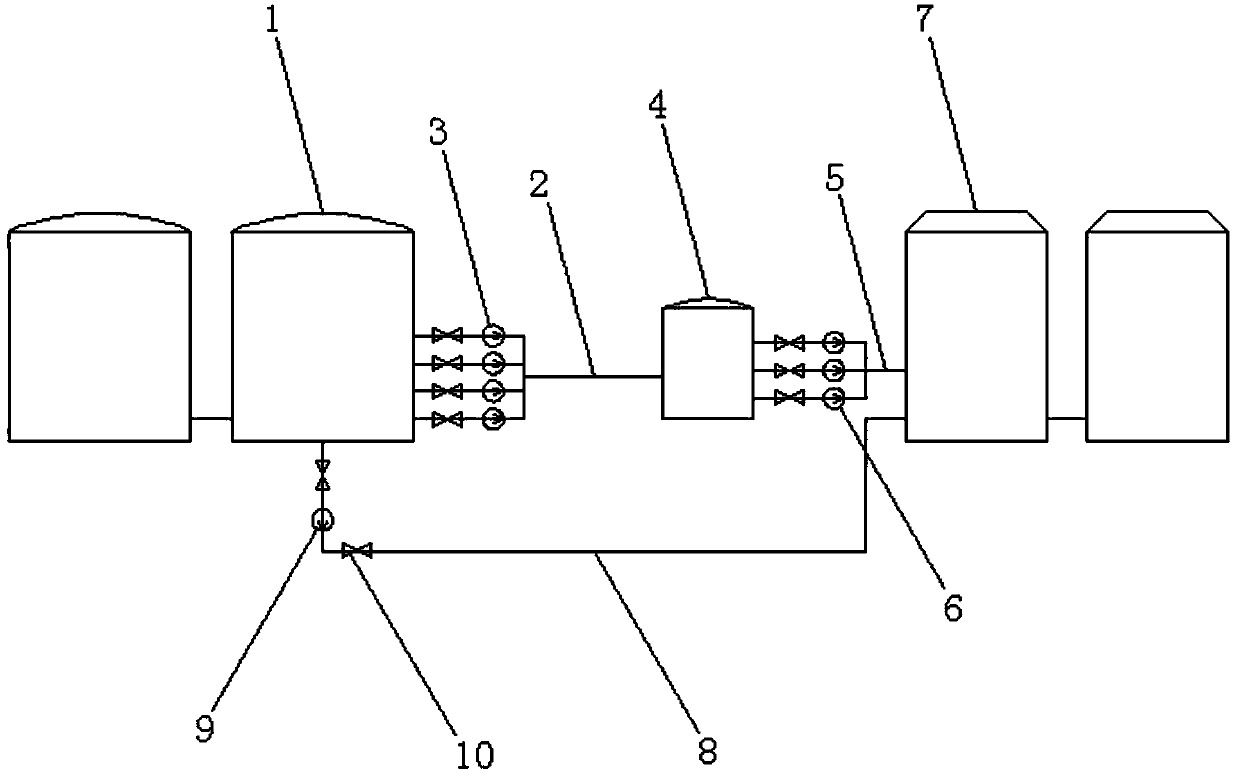

Image

Examples

Embodiment Construction

[0032] The method for supplementing water by blowing pipes with stable pressure steam of supercritical units comprises the following steps:

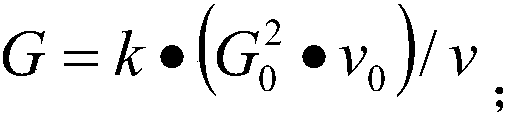

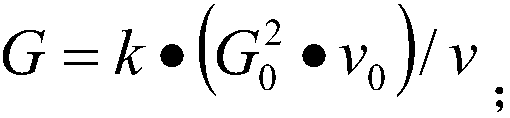

[0033] Use the pressure drop method to monitor the momentum of the steam when the pressure-stabilizing steam is blown, and take a small section in the pressure-stabilized steam blowing system. When the section is small enough, the specific volume of the steam in this section can be regarded as a constant. At this time The resistance to flow through this section is:

[0034] ΔP=ξ[C 2 (2g·ν)];

[0035] In the formula: ΔP is the resistance, ξ is the resistance coefficient, C is the average flow velocity, ν is the steam specific volume, and ɡ is the acceleration of gravity;

[0036] The subscript 0 below indicates the rated working condition, at this time:

[0037] ΔP / ΔP 0

[0038] =ζ[C 2 / (2g.v)] / ζ[C 0 2 / (2g.v 0 )]

[0039] =(C 2 / v) / (C 0 2 / v 0 )

[0040] =[(G.v / F) 2 / v] / [(G 0 .v 0 / F) 2 / v 0 ]

[0041] =(G 2 .v) / (G ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap