Novel sliding TMD capable of adjusting frequency continuously

A new type of skateboard technology, applied in building types, bridge parts, bridges, etc., can solve the problem that the frequency modulation mass damper cannot achieve continuous frequency modulation, and achieve the effect of high frequency modulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

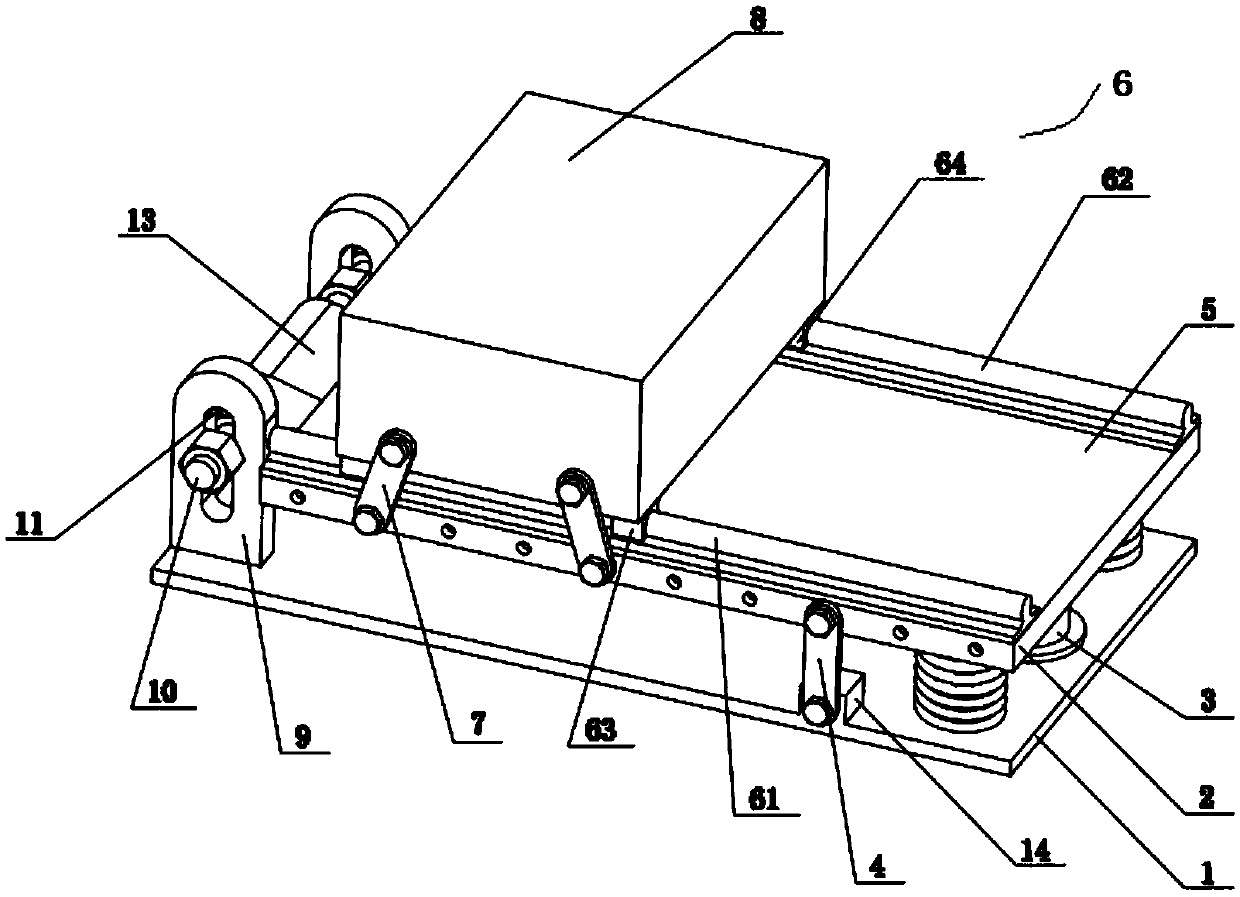

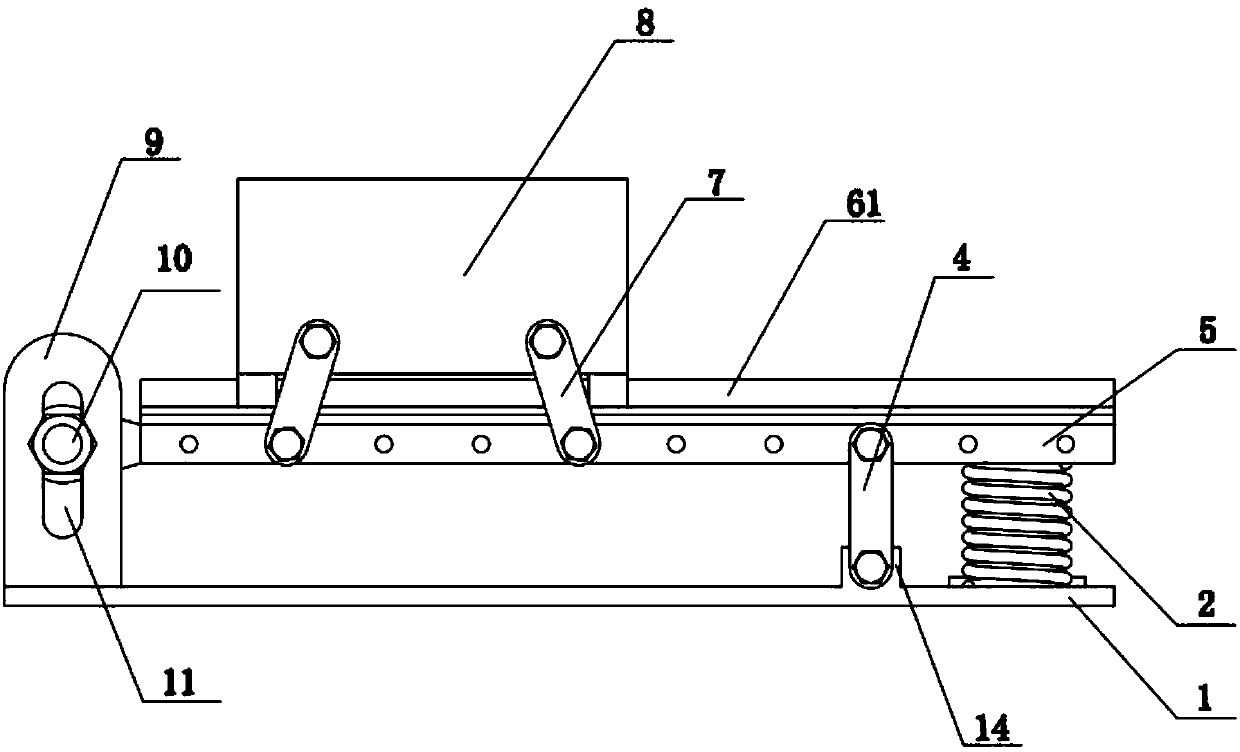

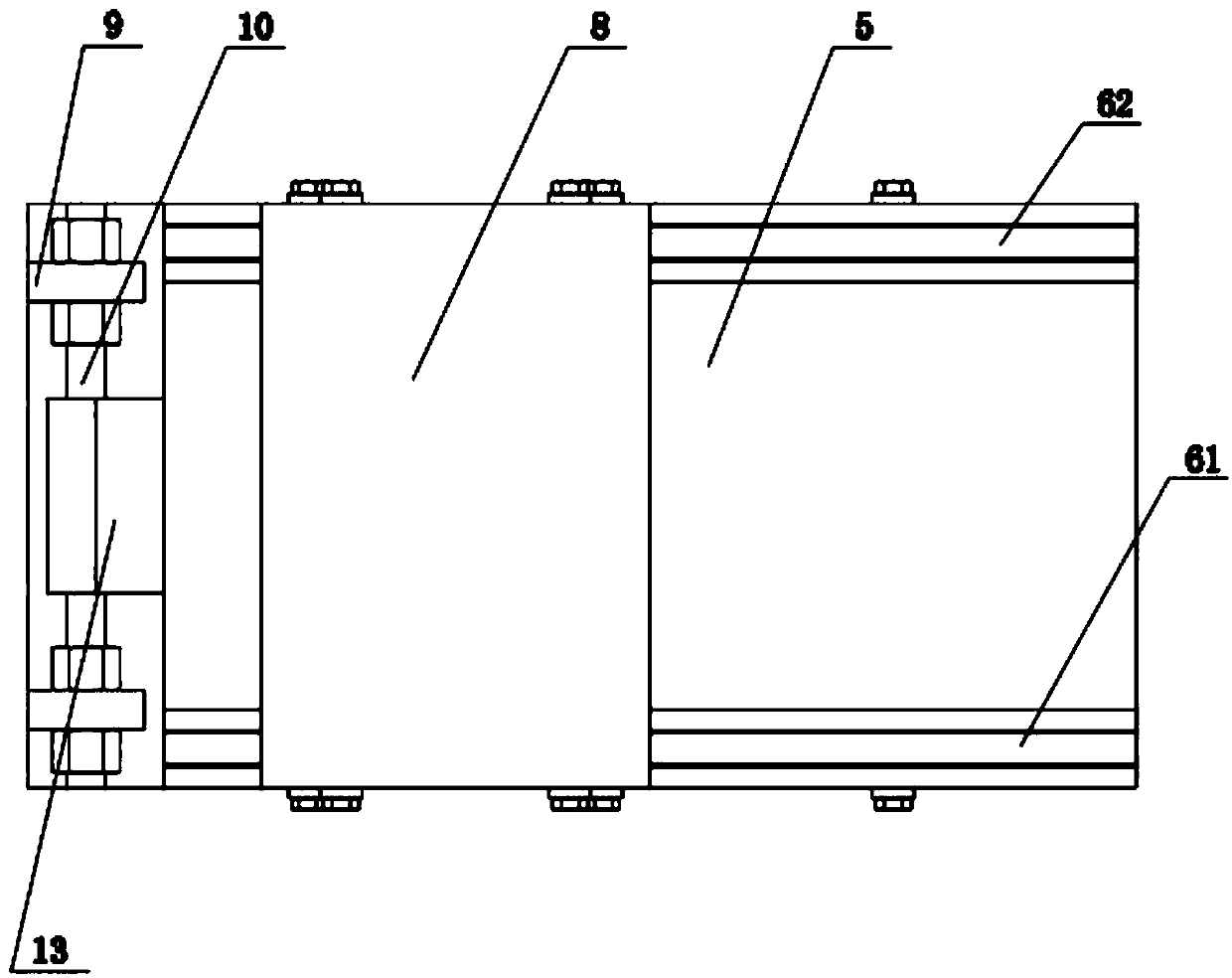

[0029] In order to solve the problems existing in the prior art, this implementation provides a structure of a new type of sliding TMD that can be tuned continuously. Specifically, refer to figure 1 , figure 2 , image 3 and Figure 4 , comprising a spring 2, an adjustment plate 9, a rotating connecting plate 5, a damper 3, a mass block 8 and a support 1, and the adjustment plate 9, the spring 2 and the damper 3 are all arranged on the support 1 , and the adjustment plate 9 and the spring 2 are respectively arranged at both ends of the support 1, one end of the rotation connection plate 5 is connected to the adjustment plate 9 in rotation, and the other end of the rotation connection plate 5 Supported by the spring 1, the mass block 8 is slidably arranged on the rotating connecting plate 5, and the height of the rotating connecting plate 5 relative to the support 1 is adjustable, and the spring 2 is positioned on the support The position on 1 is adjustable.

[0030] As a ...

Embodiment 2

[0051] refer to Figure 5 , Figure 6 and Figure 7 , In this embodiment, different from Embodiment 1, in this embodiment, the mass block 8 is arranged on the rotating connecting plate 5 through a slide plate 12, specifically, the slide plate 12 includes a first slide plate and a second slide plate Two slide plates, the first slide plate and the second slide plate are all arranged on the rotating connecting plate 5, as preferably, the material of the slide plate 12 is polytetrafluoroethylene, the first slide plate and the second slide plate are connected with the rotation The coefficient of friction between the connecting plates 5 is 0.06, and the mass blocks 8 are respectively welded and fixed to the first and second sliding plates, and the sliding movement of the first and second sliding plates on the rotating connecting plates 5 drives the The mass block 8 slides on the rotating connecting plate 5 to realize the adjustment of the position of the mass block 8 and the adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com