Anti-roll bar for vehicle

A technology for anti-rolling and vehicles, which is applied in the direction of vehicle springs, vehicle components, interconnection systems, etc., and can solve problems such as changing the effective stiffness of ARB

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

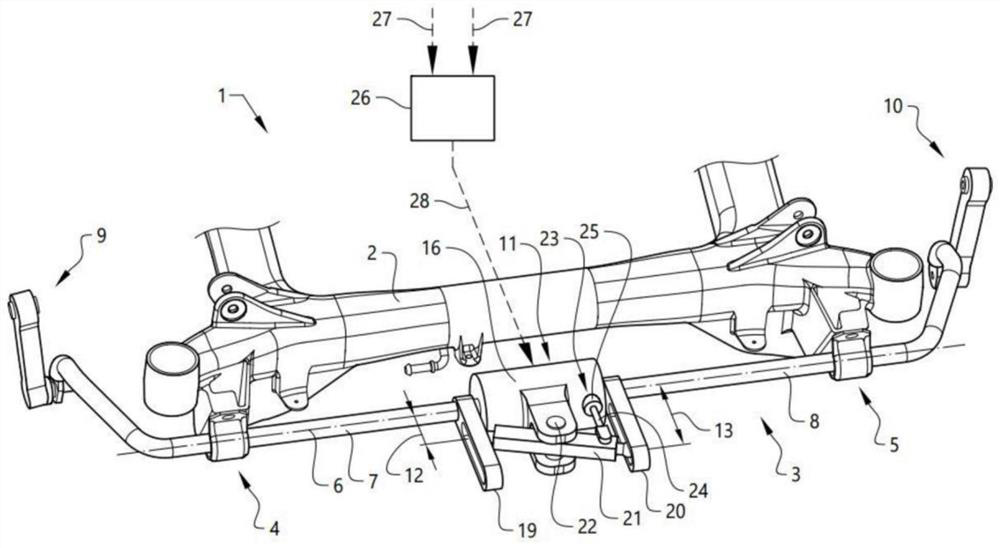

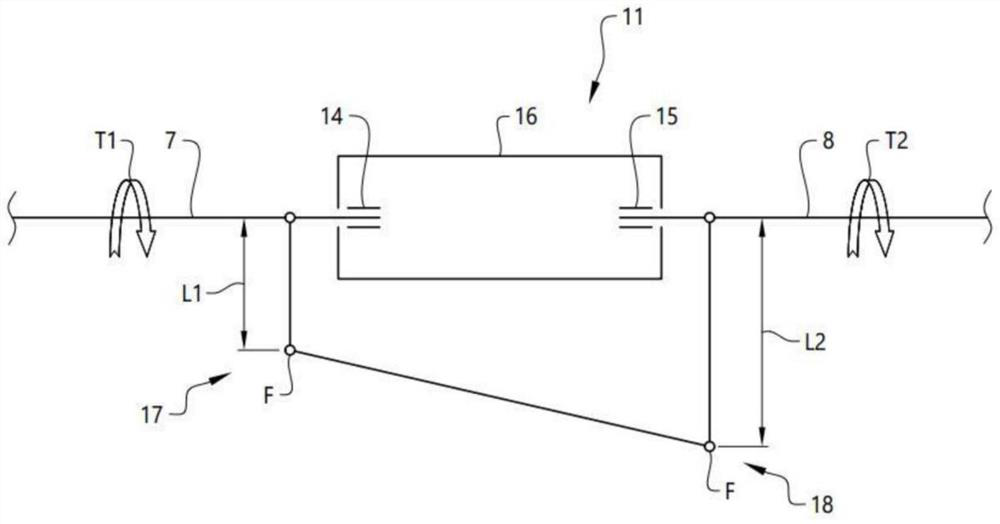

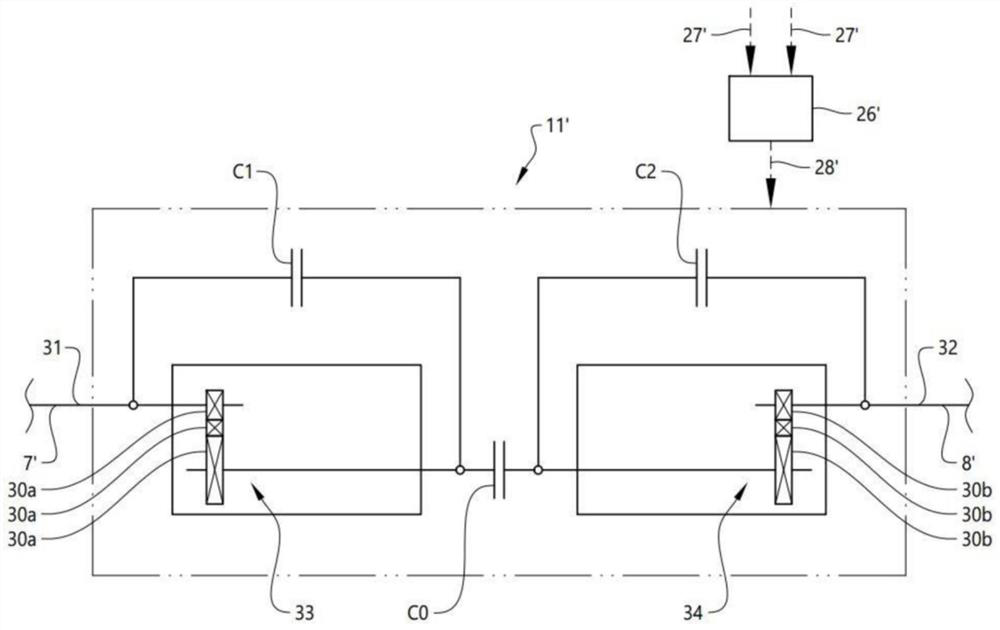

[0030] figure 1 A part of a chassis 1 of a vehicle is shown in a perspective view. The chassis 1 has a frame portion 2 and an anti-roll bar (ARB) 3 arranged on the frame portion 2 . The ARB is suitably attached to the frame part 2 at a first location 4 on the left hand side and a second location 5 on the right hand side. The ARB 3 is mounted by bearings relative to the frame part 2 at a first connection location 4 and a second connection location 5, allowing the ARB to rotate relative to the frame part 2 about a center line 6 of the ARB. ARBs are used in vehicle wheel suspension systems. ARB 3 connects the vehicle's left wheel suspension and right wheel suspension. The anti-roll bar 3 includes a first rod portion 7 for connecting a left wheel suspension (not shown) and a second rod portion 8 for connecting a right wheel suspension (not shown). The first rod part 7 has a first connection point 9 which can be connected to the left wheel suspension at the first end of the ARB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com