Back torsion beam suspension frame structure

A technology of suspension and torsion beam, which is applied in the direction of suspension, interconnection system, transportation and packaging, etc., can solve the problems of poor versatility of suspension, and achieve the effects of weight reduction, good economic benefits, and simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically described below in conjunction with the accompanying drawings.

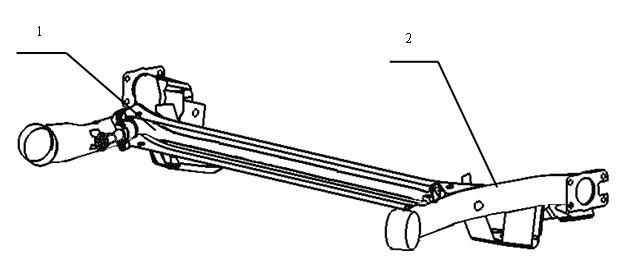

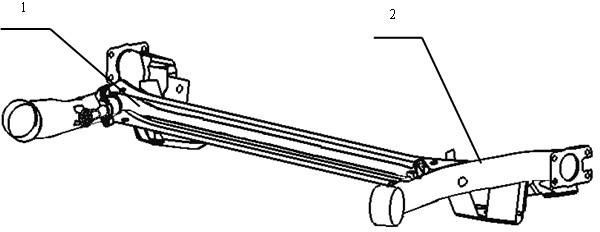

[0023] figure 1 The overall schematic diagram of the rear torsion beam suspension structure of the present invention. The stabilizer bar assembly structure 2 is installed on the rear torsion beam suspension assembly through the fixed brackets on the left and right sides, and the fixed points are connected by bolts. The suspension assembly has a symmetrical structure left and right.

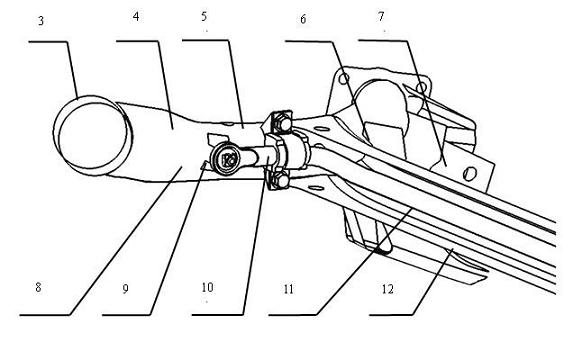

[0024] figure 2 It is a schematic diagram of the local structure where the stabilizer bar is installed. combine figure 1 , 2 , the rear torsion beam suspension structure of the present invention comprises: a left longitudinal beam 4, a right longitudinal beam 4 and a beam 12 connecting the two, as well as a bush sleeve 3, a shock absorber mounting bracket 6 and a spring mounting bracket 7, and also includes a Before installing the stabilizer bar of the stabilizer bar, install t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com