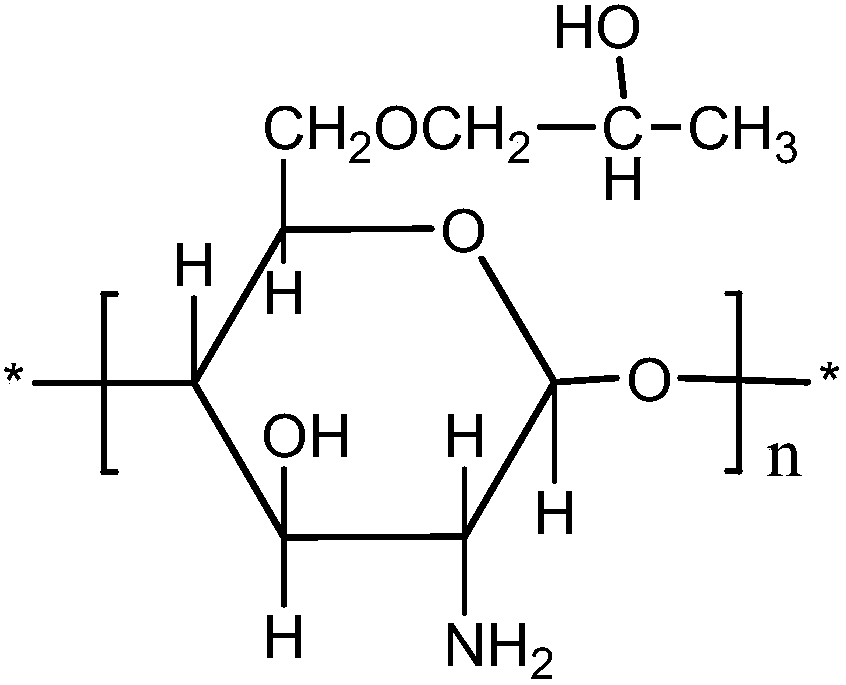

O-hydroxypropyl chitosan and preparation method thereof

A technology of hydroxypropyl chitosan and chitosan, which is applied in the field of chitosan, can solve the problems of low molecular weight of hydroxypropyl chitosan, unclear modification sites, unsuitable for flocculation products, etc., and achieve product High relative molecular weight, improved water solubility, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1, dissolving 9g of sodium hydroxide in 30mL of distilled water to obtain a sodium hydroxide solution;

[0035] Step 2: Add 1g of chitosan to the above sodium hydroxide solution and alkalize for 30 minutes; pour off the upper layer of lye, add the alkalized chitosan to 20mL of isopropanol, and stir for 30 minutes at 25r / min , and the temperature was raised to 60° C., and then slowly added 8 g of propylene oxide and 2 mL of tetramethylammonium hydroxide solution with a mass fraction of 10%, and continued to react for 6 hours to obtain a suspension a;

[0036] Step 3, the suspension a was left to stand for 30min, the supernatant was poured off, and the hydrochloric acid solution with a mass fraction of 18.5% was added to adjust the pH of the solution to 7; 2:1, suction filtration after standing, and then wash with acetone and ethanol successively to obtain filter cake b;

[0037] Step 4, the filter cake b was Soxhlet extracted with ethanol as a solvent for 8 hours, ...

Embodiment 2

[0042] Step 1, dissolving 12g of sodium hydroxide in 30mL of distilled water to obtain a sodium hydroxide solution;

[0043] Step 2: Add 1 g of chitosan to the above-mentioned sodium hydroxide solution, and alkalize for 60 minutes; remove the upper layer of lye, add the alkalized chitosan to 20 mL of isopropanol, and stir at 25 r / min for 30 minutes. And raise the temperature to 60°C, then slowly add 10g of propylene oxide and 2mL of tetramethylammonium hydroxide solution with a mass fraction of 10%, and continue the reaction for 6h to obtain a suspension a;

[0044] Step 3, the suspension a was left to stand for 40 minutes, the supernatant liquid was poured off, and hydrochloric acid with a mass fraction of 18.5% was added to adjust the pH of the solution to 7; then 50 mL of a mixed solution of acetone and ethanol was added, and the volume ratio of ethanol and acetone was 2:1, suction filtration after standing, and then wash with acetone and ethanol successively to obtain filt...

Embodiment 3

[0050] Step 1, dissolving 9g of sodium hydroxide in 30 parts of mL distilled water to obtain a sodium hydroxide solution;

[0051]Step 2: Add 1 g of chitosan to the above-mentioned sodium hydroxide solution, and alkalize for 10 minutes; remove the upper layer of lye, add the alkalized chitosan to 20 mL of isopropanol, and stir at 25 r / min for 30 minutes. And raise the temperature to 80°C, then slowly add 15g of propylene oxide and 2mL of tetramethylammonium hydroxide solution with a mass fraction of 10%, and continue the reaction for 3h to obtain suspension a;

[0052] Step 3, the suspension a was left to stand for 50 minutes, the supernatant was poured off, and hydrochloric acid with a mass fraction of 18.5% was added to adjust the pH of the solution to 7.5; then 50 mL of a mixed solution of acetone and ethanol was added, and the volume ratio of ethanol and acetone was 2 : 1, suction filtration after standing, then wash with acetone and ethanol successively, obtain filter cak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com