Fire machine lifting device

A technology of lifting device and fire machine, applied in the direction of lifting device, lifting frame, etc., can solve the problems of high assembly cost, difficult assembly, high manufacturing cost, etc., and achieve the effect of simple structure and assembly, low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

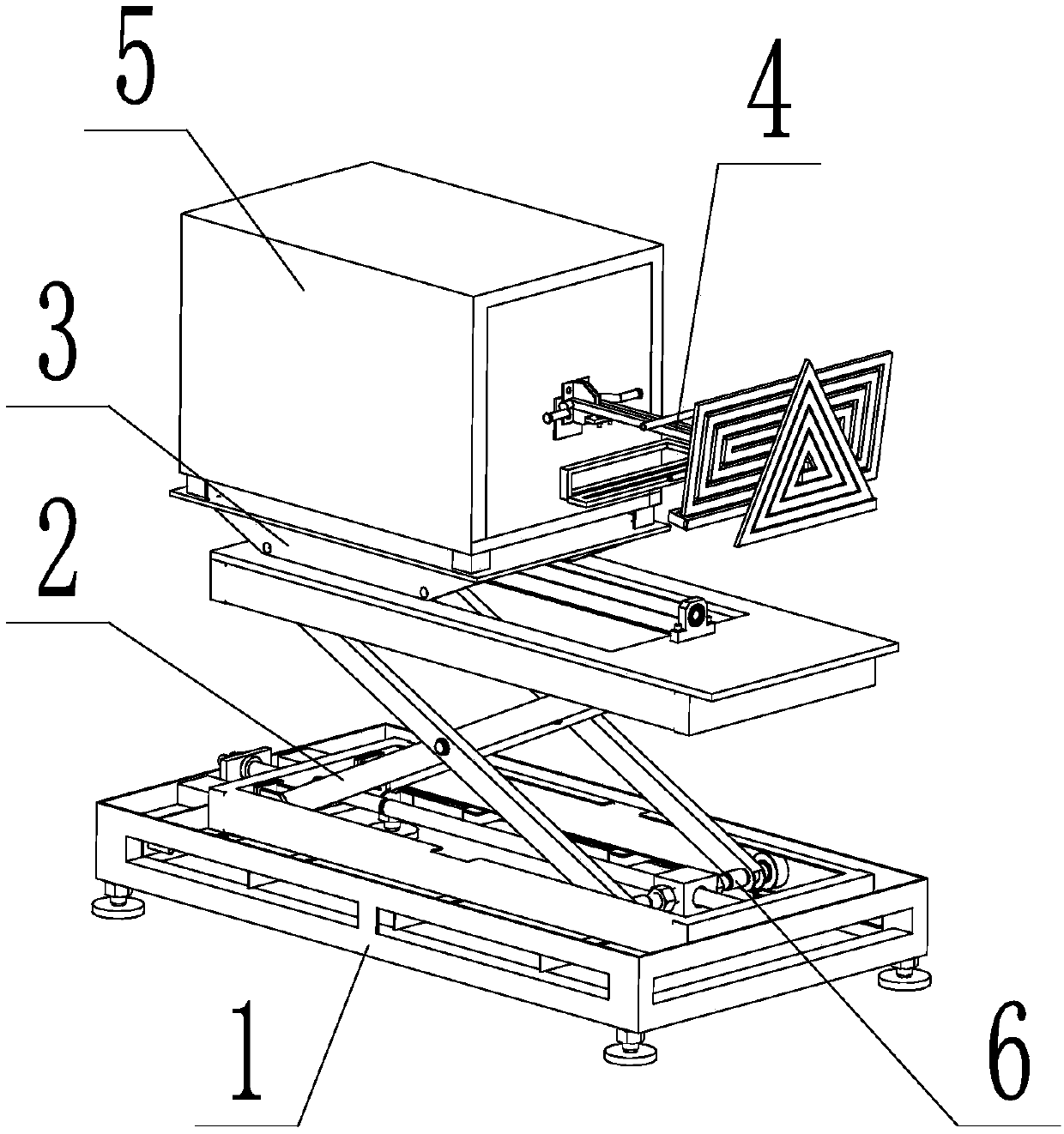

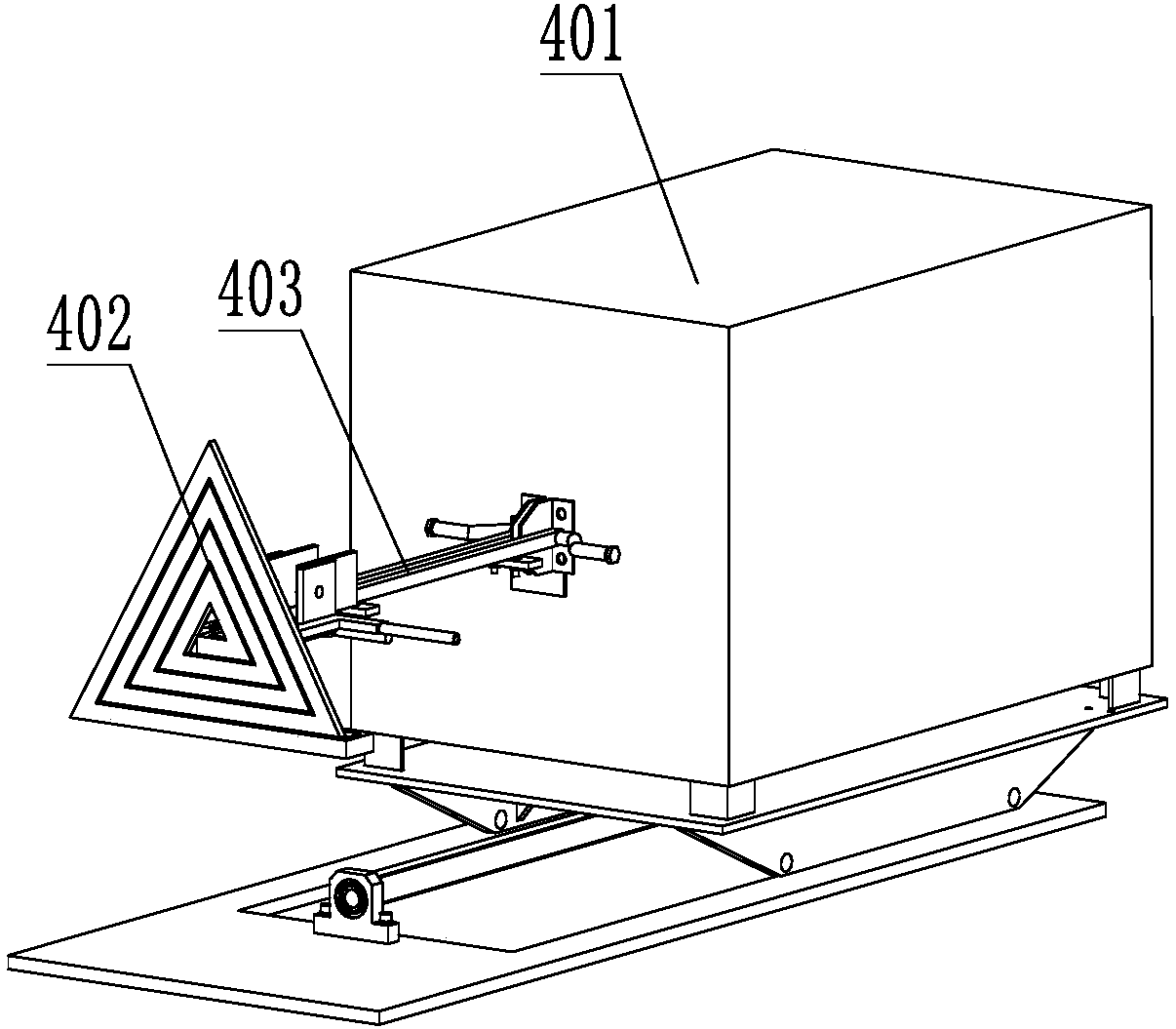

[0014] Such as Figure 1-4 As shown, the present invention includes a base 1, a lifting part 2, a moving part 3 and a heating part 4, and is characterized in that the upper part of the base 1 is provided with a lifting part 2, a moving part 3 and a heating part 4 in sequence from bottom to top, The heating part 4 is composed of a transformer 401, an inductor 402, and an induction rod 403. The outer wall of the transformer 401 is provided with a protective shell 5 with a side wall opening, and the bottom of the protective shell 5 can be moved by the moving part 3. One side of the transformer 401 is connected to an induction rod 403 protruding from one end of the protective case 5 , and one end of the induction rod 403 is connected to the inductor 402 .

[0015] The moving part 3 includes an oil cylinder 301 and a connecting piece 302 , the oil cylinder 301 is connected to the bottom of the protective case 5 through the connecting piece 302 .

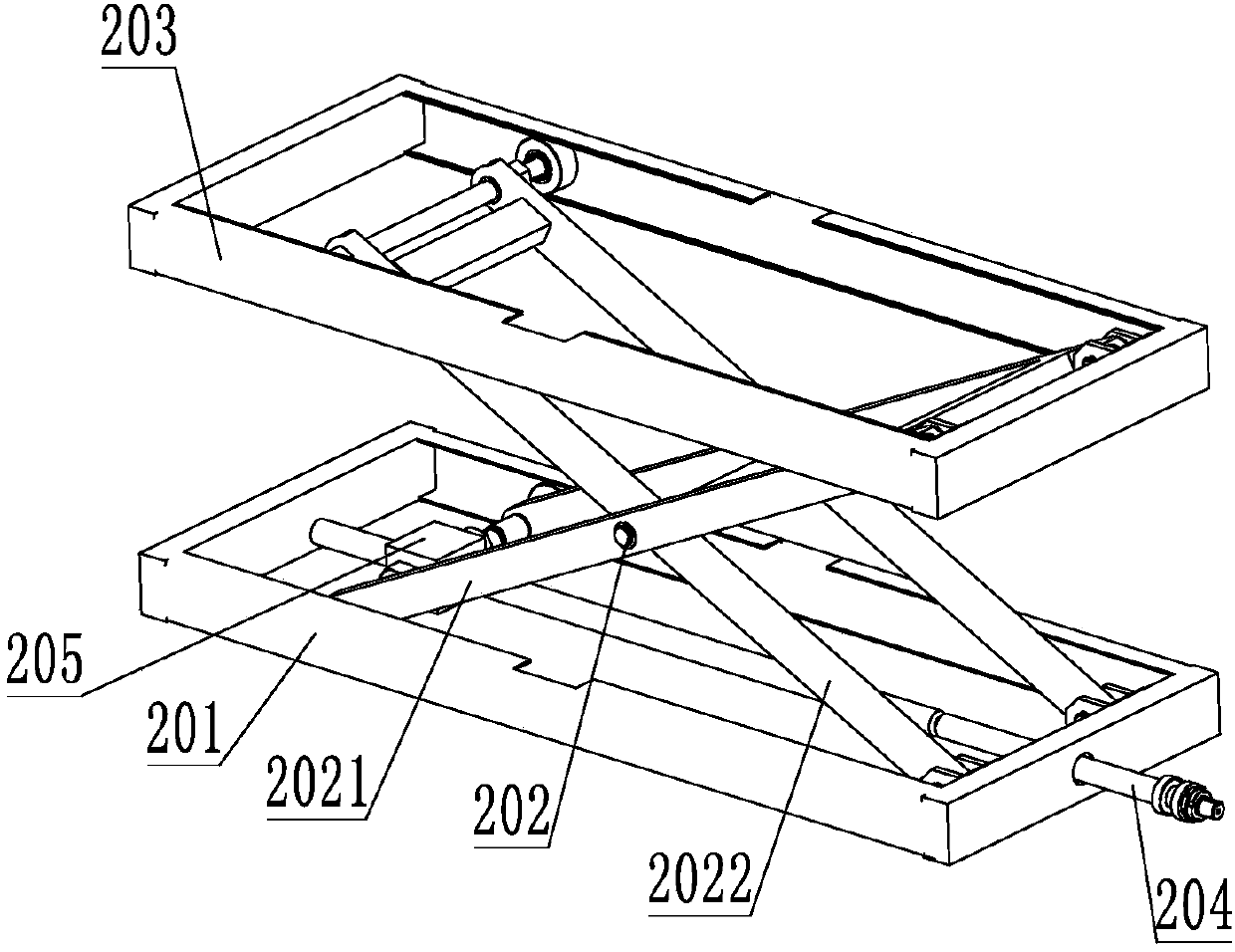

[0016] The lifting part includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com