Stacking device of stacking machine

A stacking device and stacker technology, which is applied in the field of corrugated cardboard processing equipment, can solve the problems affecting the continuous operation of the production line, no paper-beating mechanism, cardboard jamming, etc., so as to avoid irregular stacking, improve stability, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

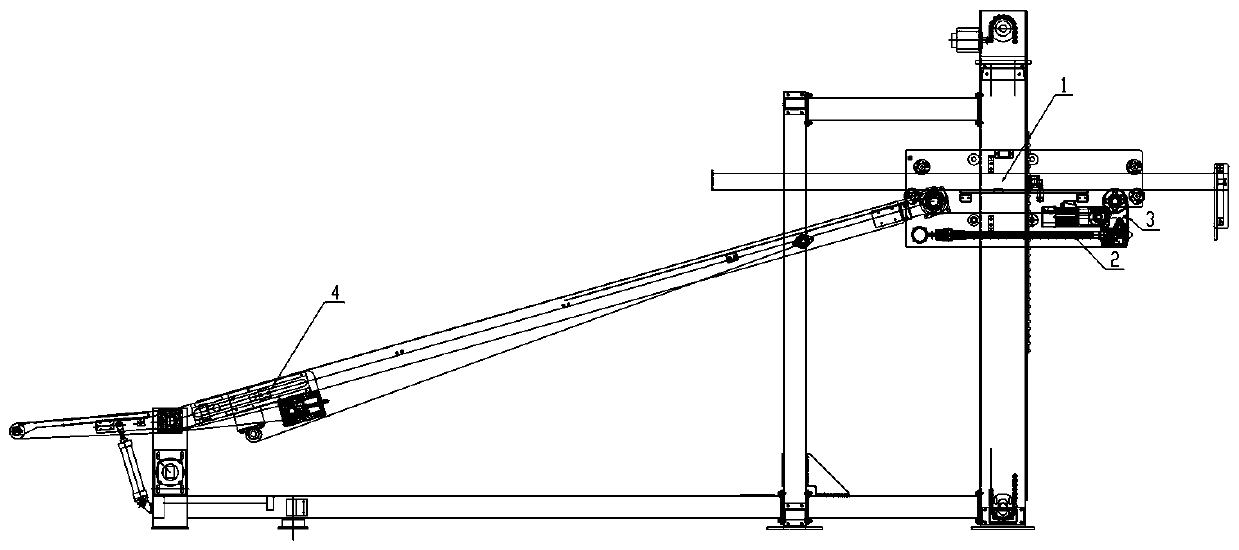

[0031] as attached figure 1 As shown, a stacking device for a stacker includes a platform sorting part 1, an automatic paper receiving part 2 and a snapping and sorting part 3, and the automatic paper receiving part 2 and the snapping and sorting part 3 are respectively installed on the platform sorting part 1, The snapping and sorting part 3 is installed on the front end of the automatic paper receiving part 2 , and the snapping and sorting part 3 is used in conjunction with the automatic paper receiving part 2 .

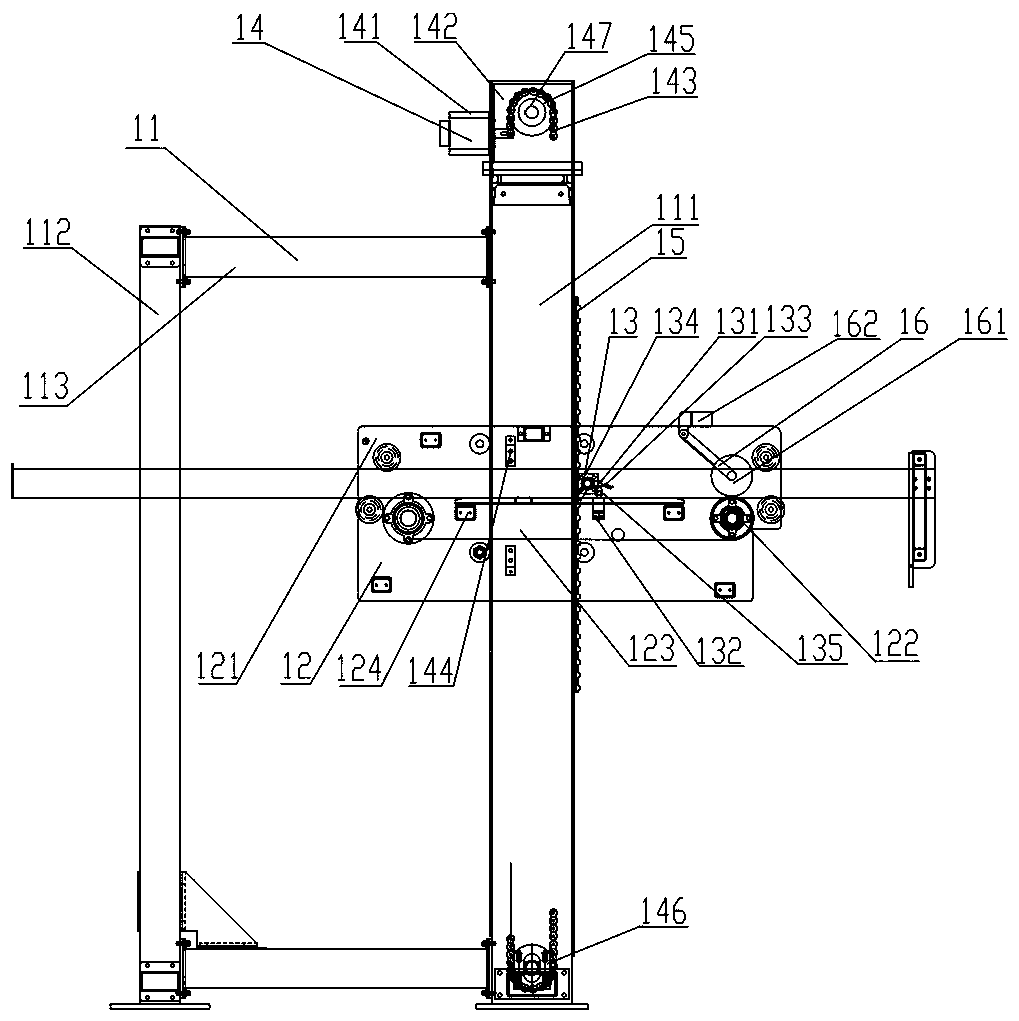

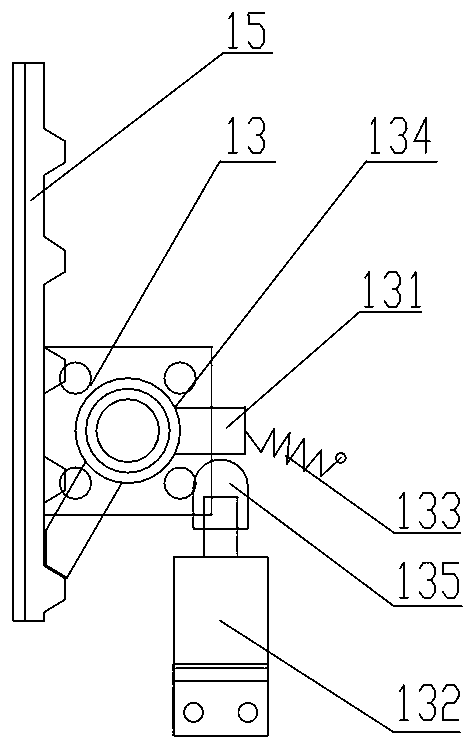

[0032] as attached figure 2 As shown, the platform finishing part 1 includes a platform lifting frame 11, a platform finishing mechanism 12 and a safety limit mechanism 13. The platform finishing mechanism 12 is installed on the platform lifting frame 11, and the safety limit mechanism 13 is installed on the platform finishing mechanism 12. The lifting frame 11 is provided with a drive mechanism 14 for driving the platform finishing mechanism 12 to move up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com