Method for pressing and shake-out for large steel casting

A technology for steel castings and press boxes, which is applied in the field of box-packing and large-scale steel casting press boxes, can solve problems such as affecting the production efficiency of factories, large physical injuries to operators, poor operability, etc., to achieve short-process production of castings, The effect of shortening production cycle and pressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A method for pressing and boxing large-scale steel castings, the method comprising the following steps:

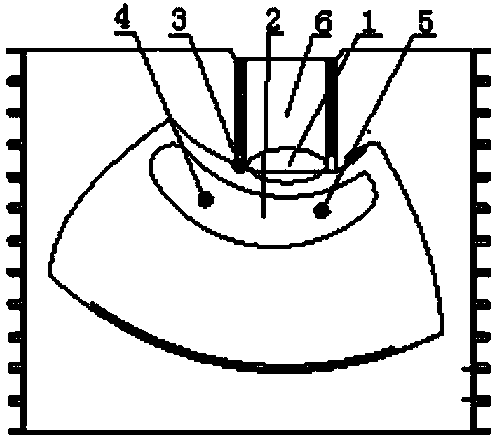

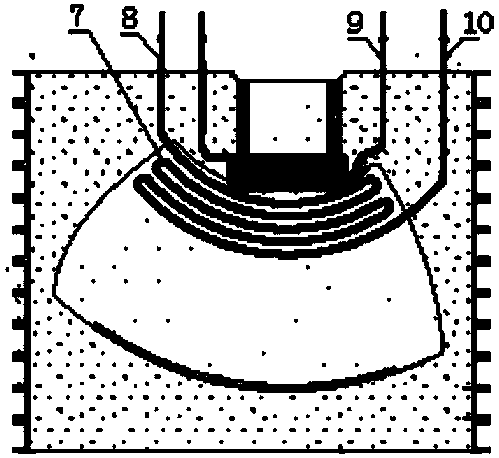

[0029] a. Determine the part of the casting that needs to be cooled and determine the temperature measurement point: use computer software to simulate the cooling sequence of each part of the casting, and determine the final solidification part of the casting, which is the part that needs to be forced to cool; or apply the modulus calculation method, the modulus The largest part is the part that requires forced cooling. Casting parts need to be cooled such as figure 1 Shown: the cooling part of the casting is (1), the (1) is the lower part of the open riser (6) of the part, and the (2) is the most thick part of the water inlet edge of the blade, which is 1000mm away from the water inlet edge Within the range, (2) is a symmetrical front and back, (1), (2) corresponding temperature measurement points are (3), (4), (5);

[0030] b. Determine the casting temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com