Individual drive for detaching rollers of a combing machine

A technology for separating rollers and combers, which is used in combers, textiles and papermaking, fiber processing, etc., can solve the problems of complex and expensive layout, and achieve the effect of reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

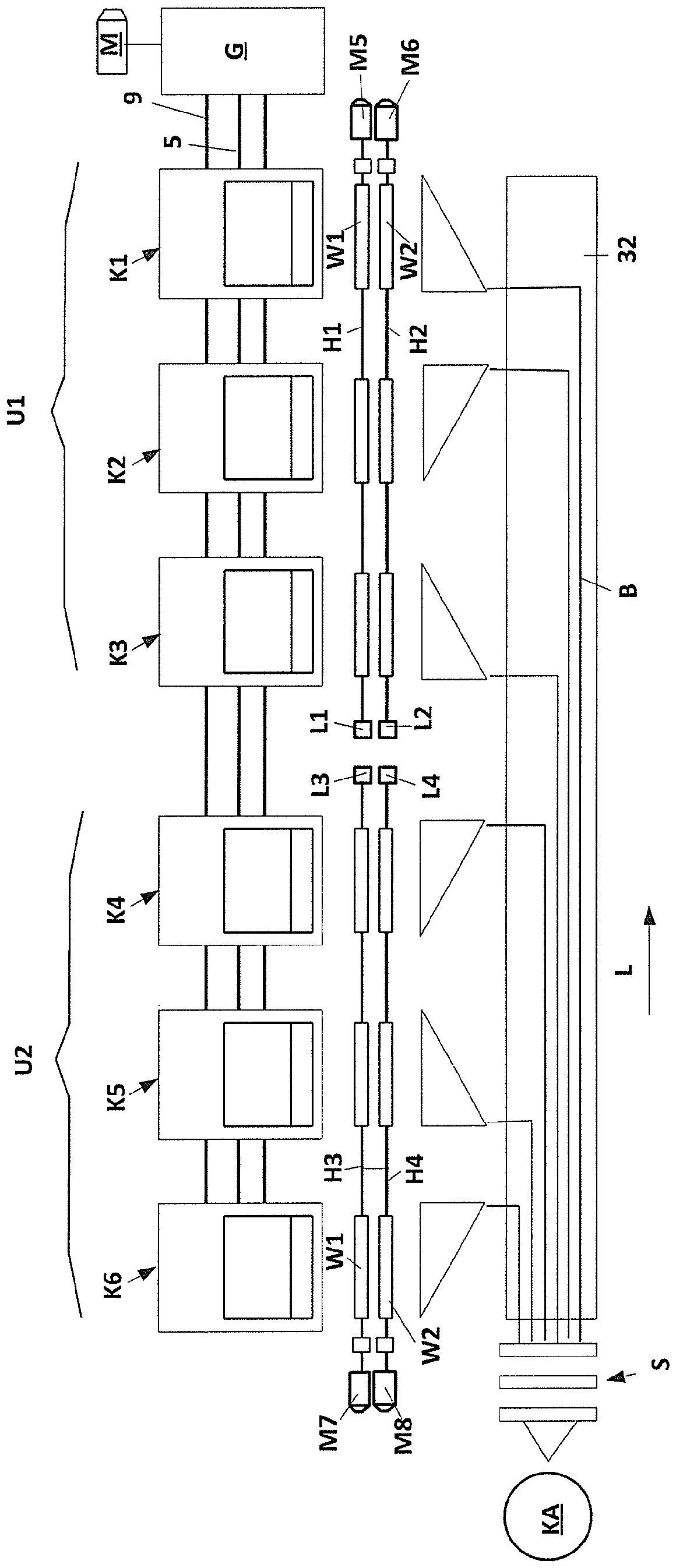

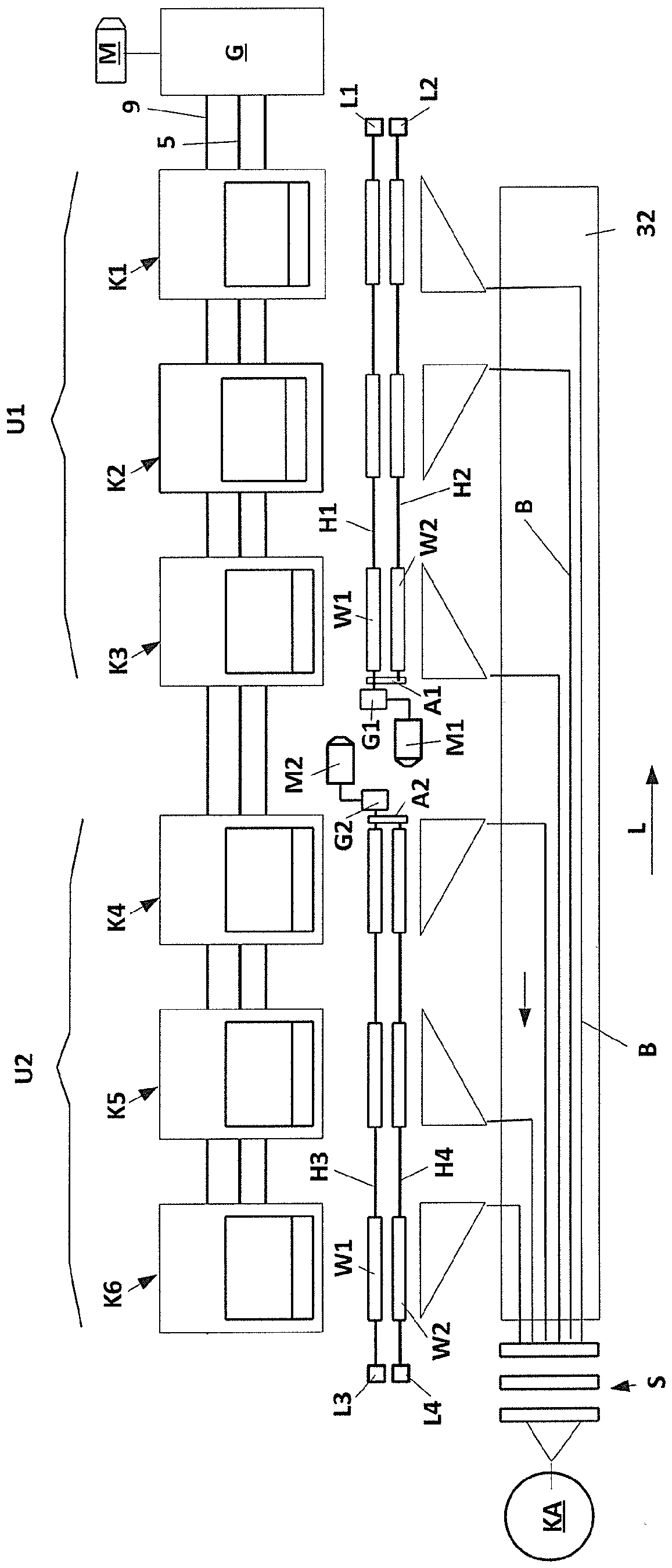

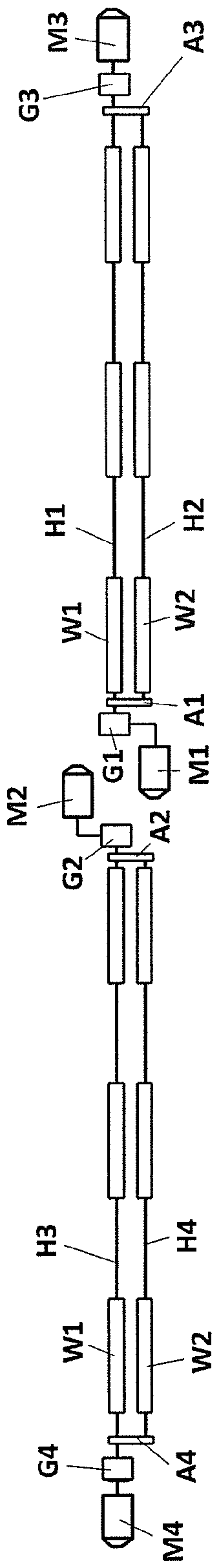

[0024] figure 1 A known embodiment of a combing head (s) K1 of a combing machine is shown, which has a pincer unit 1 (referred to simply as "pincer") which is mounted so that it can be moved by means of crank arms 2, 3. pivotally move. The two crank arms 2 are respectively mounted pivotably on their shaft 5 on the sides of the cylinder comb (also called "circular comb"). The other end of the pivot arm 2 is attached to a lever shaft 13 on the jaw frame 8 so as to be rotatably movable. The rear pivot arm 3 (possibly two) is mounted in a rotatably fixed mount on the tong shaft 10 . The opposite free end of the pivot arm 3 is connected to the jaw frame 8 so as to be rotatably movable by a shaft 9 .

[0025] The combing cylinder 4 has on a part of its circumference a combing section 7 which, as schematically shown, is provided with a combing card clothing and is driven in the direction of rotation D. As shown in FIG.

[0026]In this example, the pliers 1 comprise a lower nipper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com