Model-plant mismatch detection using model parameter data clustering fortransverse process behavior monitoring

A model, behavioral technology, applied in the direction of comprehensive factory control, comprehensive factory control, simulator, etc., can solve problems such as difficulty in using routine operation data, interference with product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

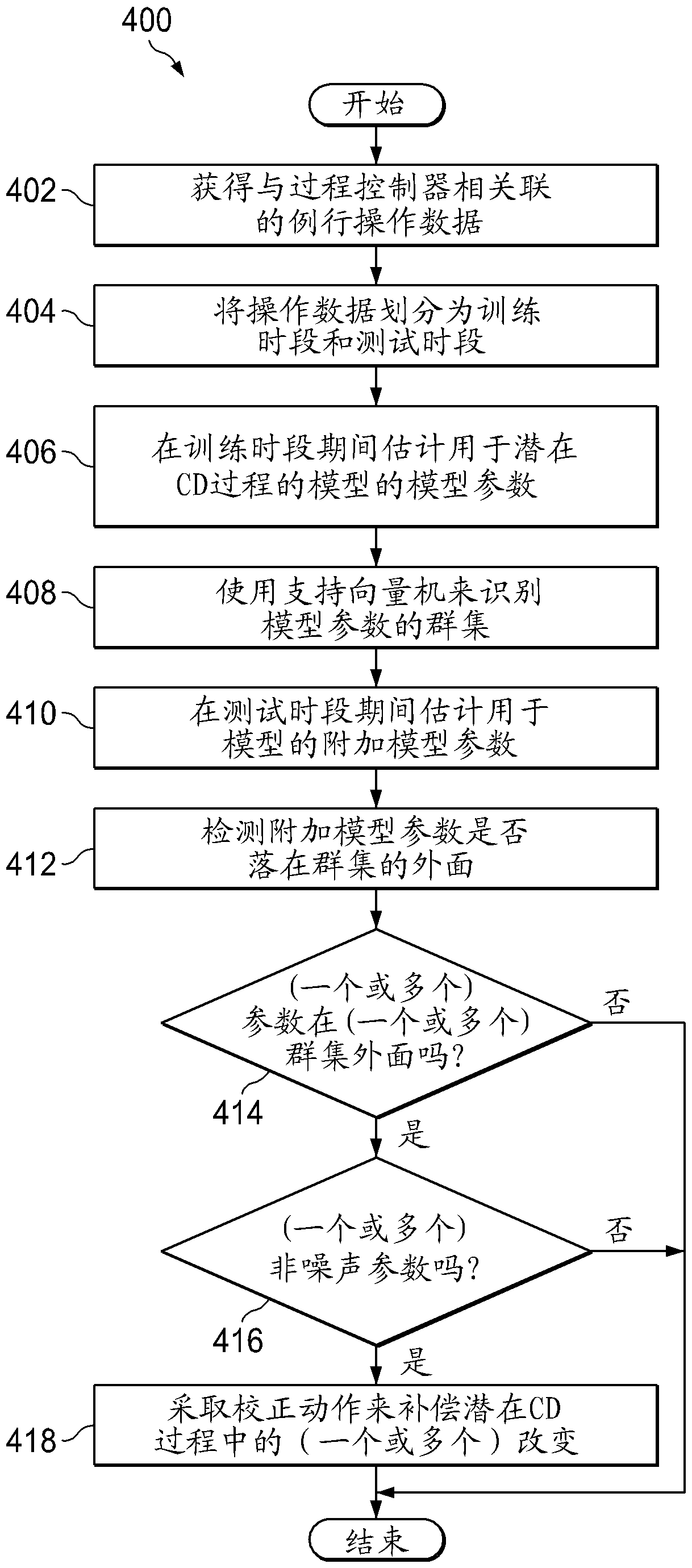

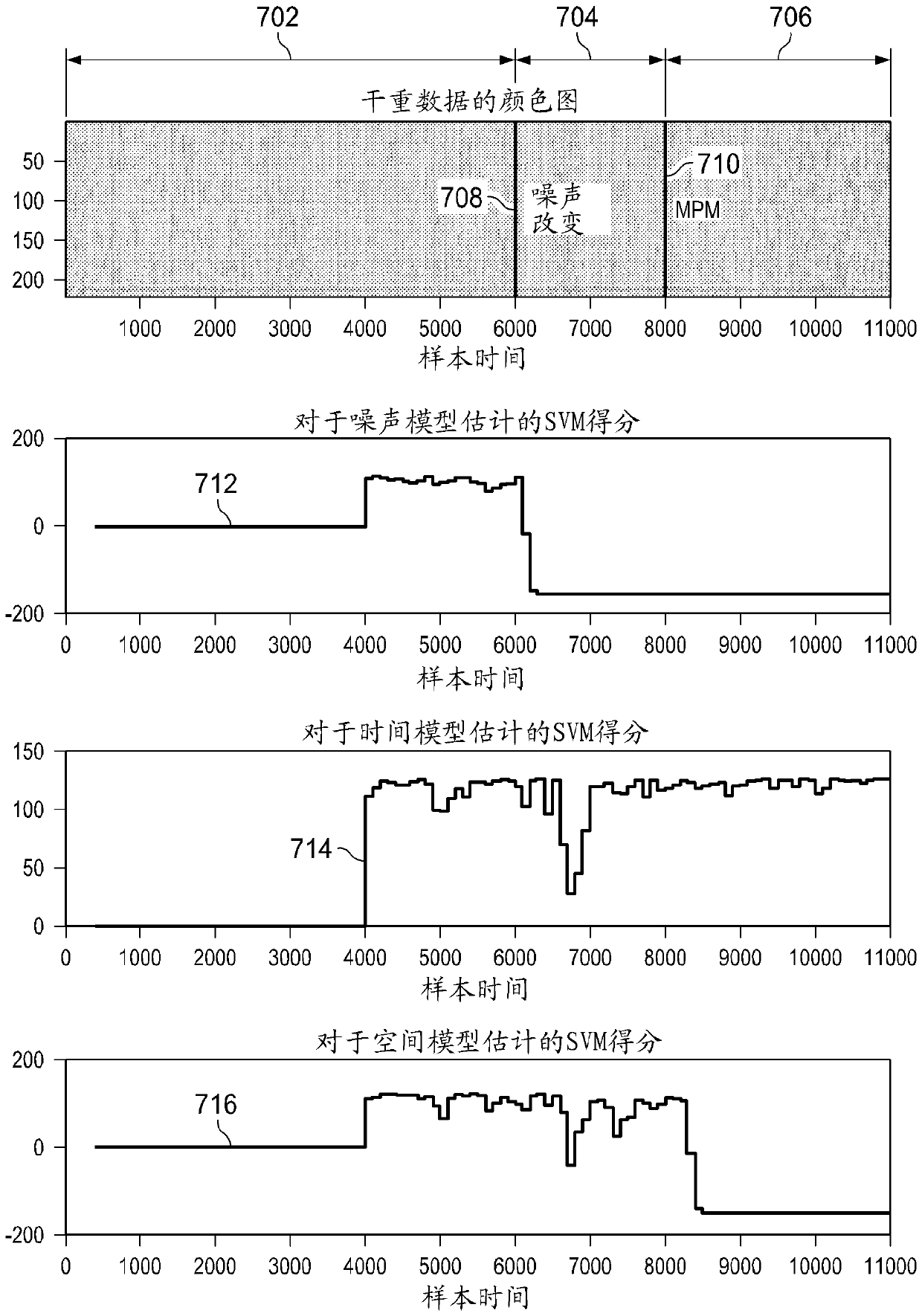

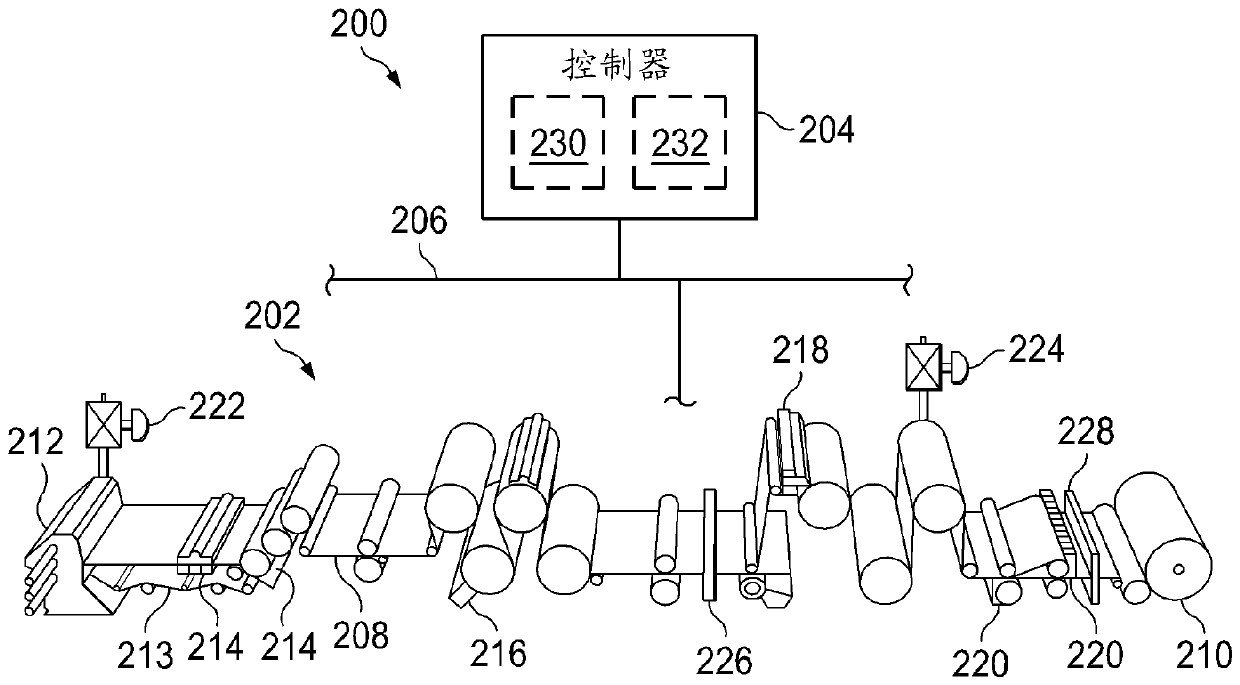

[0017] In this patent document, the following discussed Figure 1 to Figure 7 And the various embodiments used to describe the principles of the invention are by way of illustration only and should not be construed in any way to limit the scope of the invention. Those skilled in the art will understand that the principles of the invention may be implemented in any type of suitably arranged device or system.

[0018] As noted above, a model-based industrial process controller is one type of process controller that is routinely used to control the operation of an industrial process. Model-based process controllers typically use one or more models to mathematically represent how one or more properties within an industrial process respond to changes made to the industrial process. Model-based controllers generally require an accurate model of process behavior in order to perform well. As conditions associated with an industrial process change, models for the process often need t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com