Imaging lens and laser thickness measurement device employing same

An imaging lens and laser thickness measurement technology, applied in the direction of using optical devices, measuring devices, optics, etc., can solve the problems of small measurement range and low measurement accuracy of rangefinders, and achieve small lens length, high measurement accuracy, and accurate calibration. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

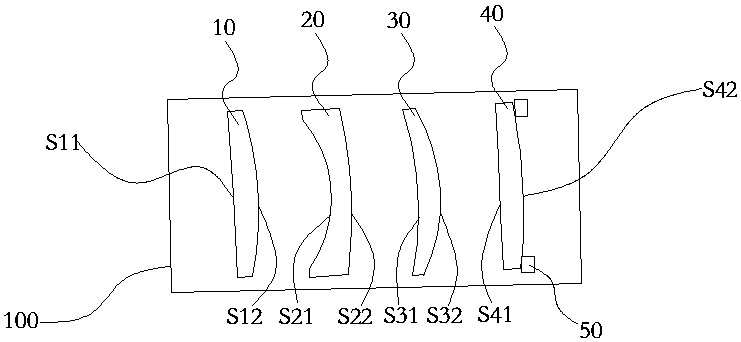

[0032] figure 1 A schematic structural diagram of an embodiment of the imaging lens of the present invention is shown, which is also a schematic diagram of a preferred embodiment. Such as figure 1 As shown, the imaging lens 100 described in this embodiment sequentially includes from the object side to the image side along the optical axis: a first lens 10 with positive refractive power, the first lens has a first object facing the object side Side S11, a first image side S12 facing the image side; a second lens 20 with negative refractive power, the second lens 20 has a second object side S21 facing the object side, facing the image side The second image side S22 of the; has the third lens 30 of positive refractive power, and the third lens 30 has the third object side S31 toward the object side, the third image side S22 toward the image side; and has The fourth lens 40 with positive refractive power, the fourth lens 40 has a fourth object side S41 facing the object side, an...

Embodiment 2

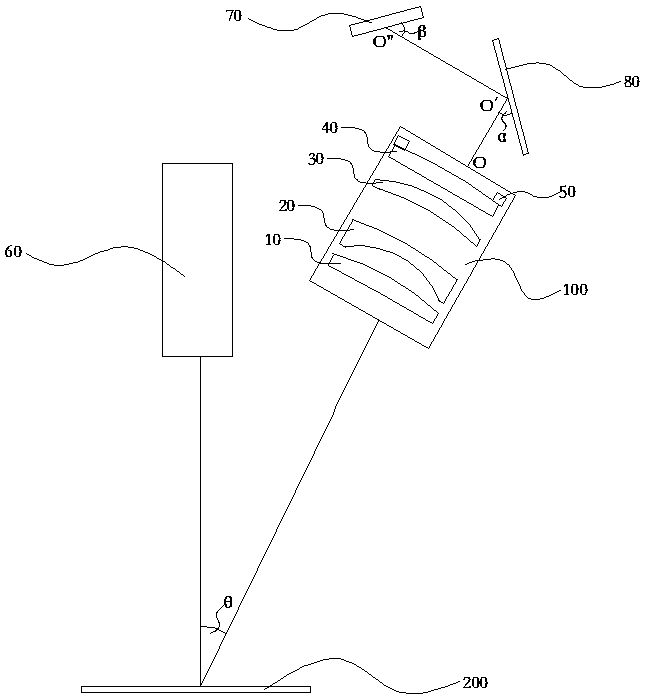

[0036] This embodiment provides a laser thickness measuring device using the imaging lens 100 described in Embodiment 1, such as figure 2 As shown, the laser thickness measuring device described in this embodiment includes: a laser 60, the imaging lens 100 described in Embodiment 1, and a photodetector 70. The laser beam emitted by the laser 60 passes through the object to be measured 200, the imaging The first lens 10 , the second lens 20 , the third lens 30 and the fourth lens 40 of the lens 100 converge on the photodetector 70 afterward.

[0037] As a preferred implementation mode, the imaging size X of the photodetector 70 in this embodiment is:

[0038]

[0039]Wherein, Y and L are respectively the maximum and minimum distances between the laser 60 and the object to be measured 200, L-Y is the thickness of the object to be measured, f is the focal length of the imaging system, and l is the distance from the laser to the center of the imaging lens.

[0040] As a prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com