A zinc phthalocyanine based/tio 2 Nanorod Composite Photoelectrochemical Sensors and Their Applications

A composite material, photoelectrochemical technology, applied in the field of photoelectrochemical sensors, can solve problems such as high cost and inconvenient detection, and achieve the effects of low cost, reduced composite, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

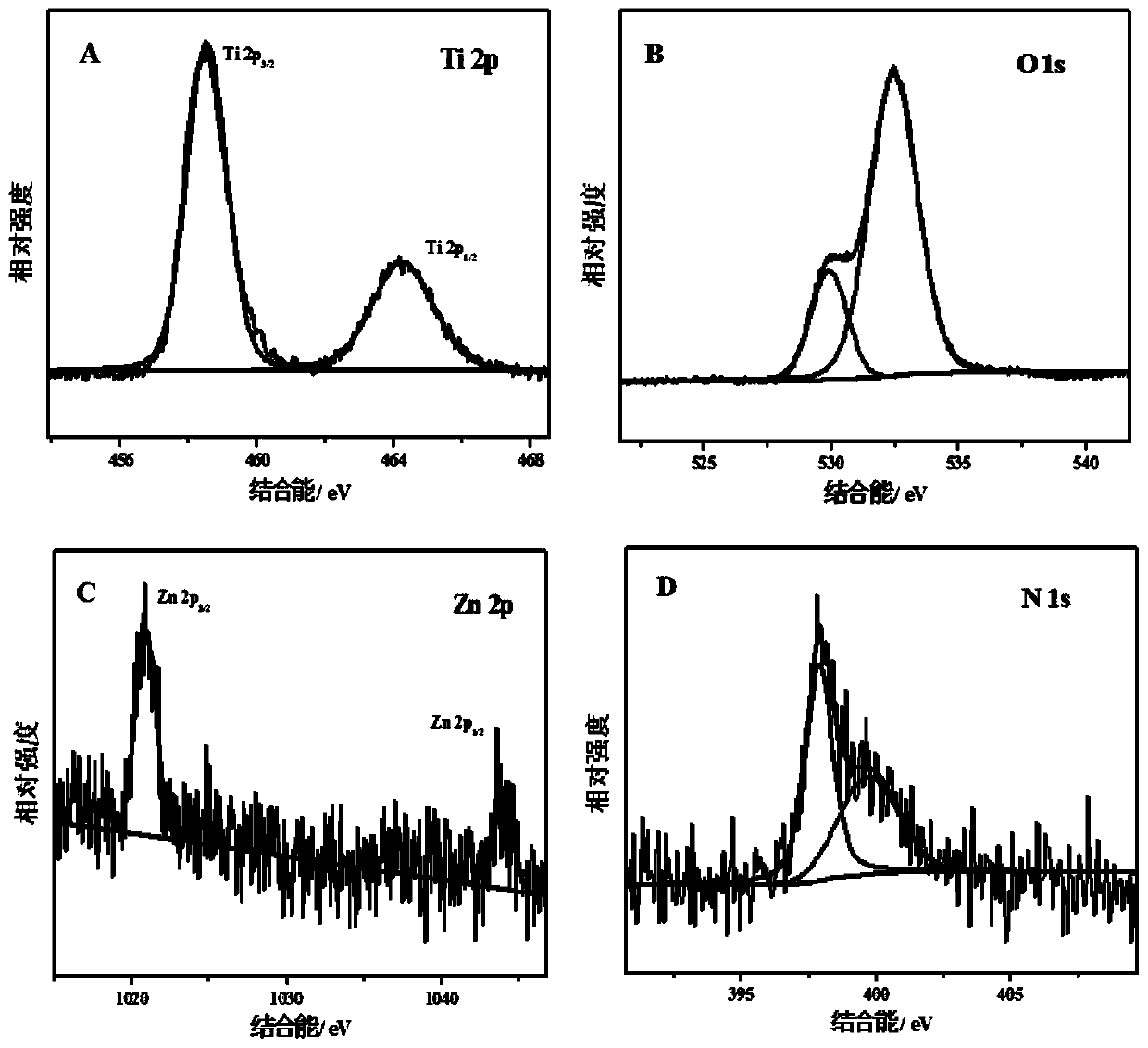

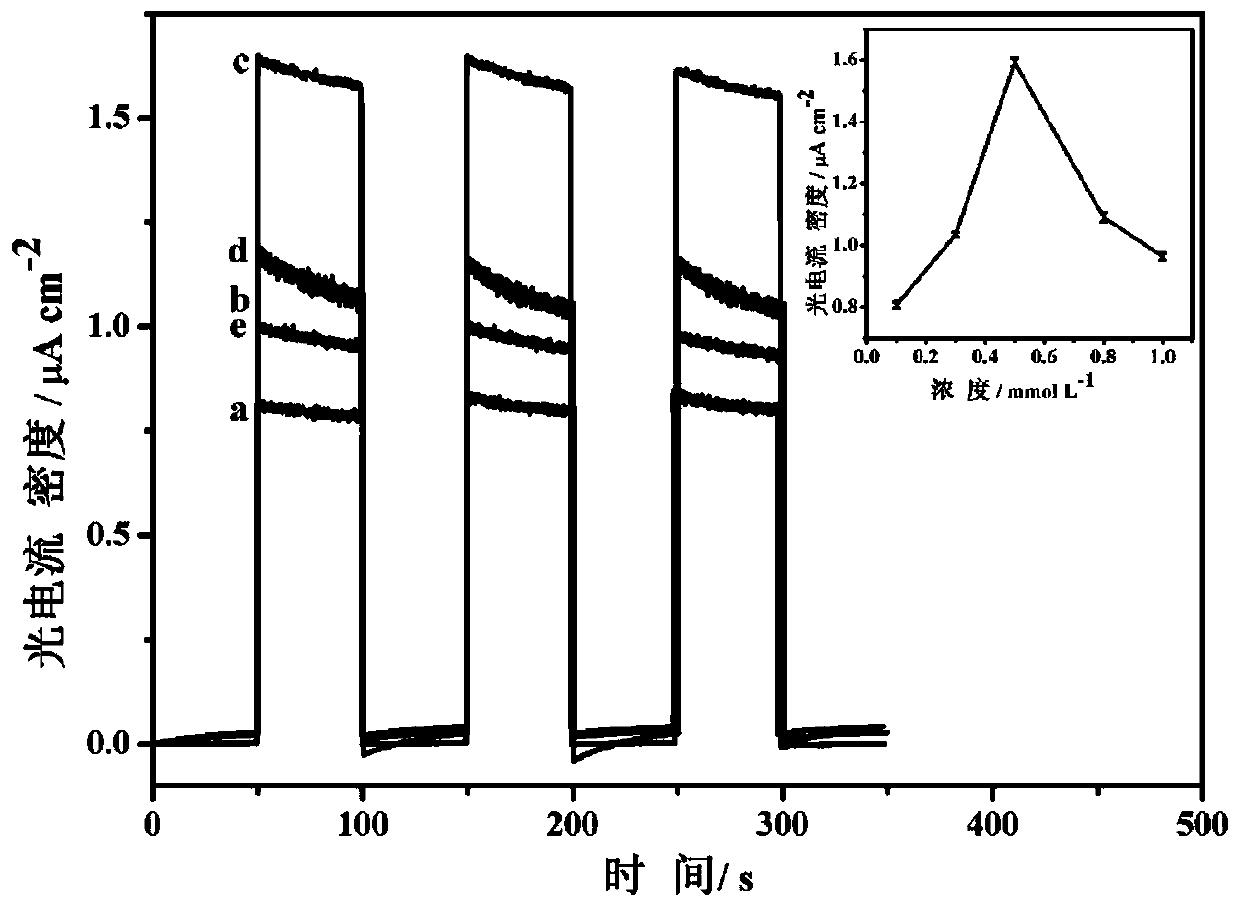

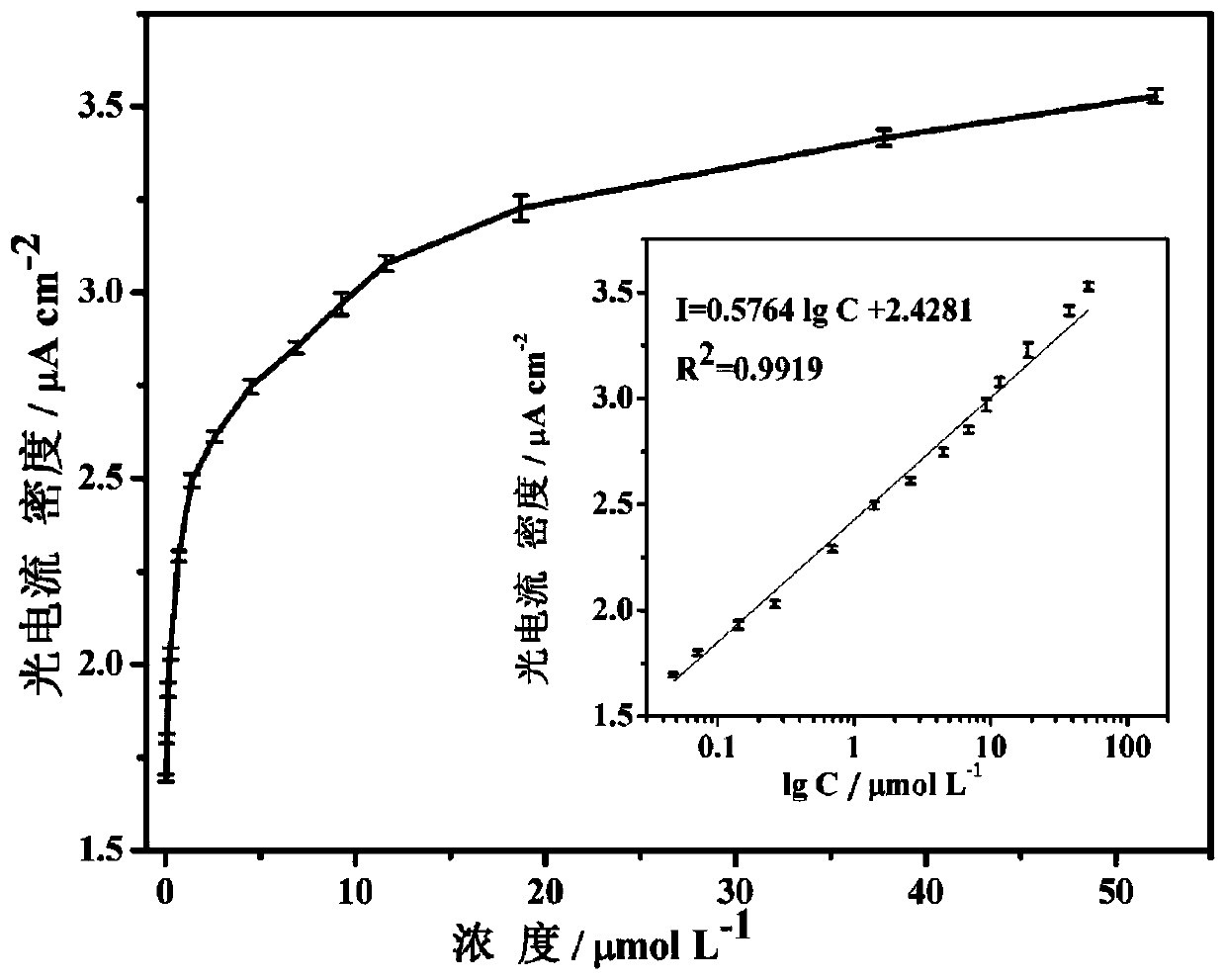

[0035] Based on zinc phthalocyanine / TiO 2Construction methods of photoelectrochemical sensors based on nanorod composites:

[0036] (1) TiO 2 Construction of nanorods: Using tetrabutyl titanate as titanium source and saturated sodium chloride solution as dispersant, TiO was directly synthesized on FTO conductive glass by one-step hydrothermal method 2 Nanorods and FTO conductive glass (15×50 mm) were ultrasonically cleaned with acetone, ethanol, and ultrapure water for 15 minutes respectively, and dried naturally for use. Mix 12.5mL of deionized water and 2.5mL of saturated sodium chloride solution, add 15mL of concentrated hydrochloric acid, mix and stir for 5min, then add 0.4mL tetrabutyl titanate and continue stirring for 5min, and transfer the obtained homogeneous solution to a 50mL autoclave , after cleaning and drying, the conductive surface of the FTO conductive glass leans downward and leans against the wall of the reactor, and puts it into an oven at 180°C for 6 hou...

Embodiment 2

[0045] Actual sample testing:

[0046] Choose PC plastic bottles, PC baby bottles, and PVC food packaging bags as raw materials, cut them into pieces, wash and dry them with ultrapure water, accurately weigh 2.0g into a conical flask, add 40mL of dichloromethane until the plastic is completely dissolved, and then Add 100mL of methanol to it to precipitate the high-molecular substances, centrifuge to take the supernatant, and evaporate it to dryness, then dilute to 5mL with ethanol, filter through a 0.45μm filter membrane, and add 0.1mol / L Na 2 SO 4 solution to 20 mL. Using the current-time curve method in Example 1, under the irradiation of visible light, a bias voltage of 0.0 V was applied to measure the photocurrent density of the above solution. Then add a concentration of 1 × 10 -6 mol / L bisphenol A standard solution for photocurrent density measurement, and calculate the concentration and recovery rate of the actual sample according to the working curve.

[0047] Mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com