Overspeed braking bearing wheel for manually-operated sliding door

An overspeed braking and sliding door technology, applied in door/window fittings, wing leaf parts, wing leaf suspension devices, etc., can solve the problem of inability to grasp the deceleration or stop of the door body, and achieve the effect of easy manual control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

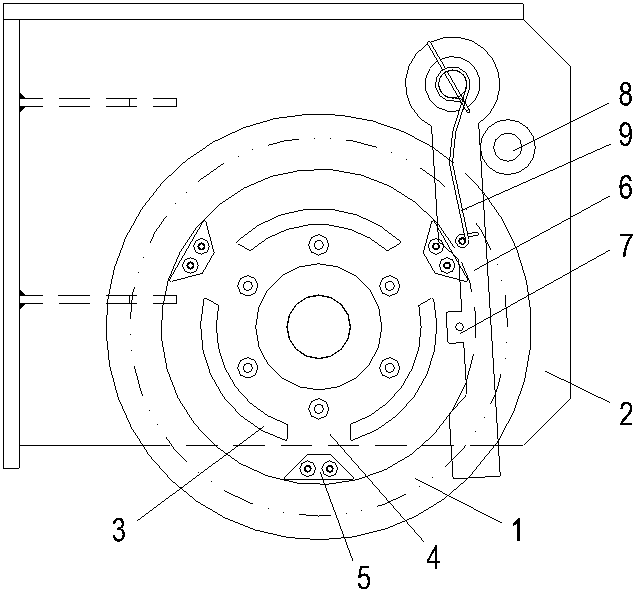

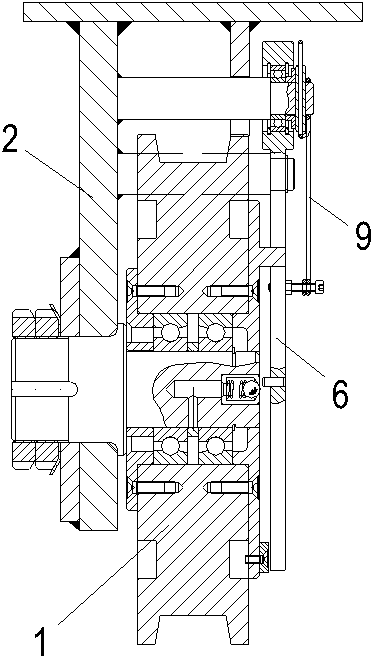

[0014] Such as figure 1 , 2 Shown is a load-bearing travel wheel for overspeed braking of a manual sliding door, including a travel wheel 1, which is installed on a travel wheel fixing seat 2, and the surface of the travel wheel 1 is provided with a ring protrusion 3, and the upper edge of the ring protrusion 3 A plurality of grooves 4 are arranged at the equally divided position of the circumference, and the number of the grooves 4 is three or more than three. There is a collision block 5, a pendulum plate 6 is installed on the fixed seat 2 of the traveling wheel, and the lower part of the pendulum plate 6 is installed on the surface of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com